Aluminum processors face constant challenges to their aluminum melt operations. Due to robust demand, processors often operate these furnaces at higher temperatures to maximize production rates. As a result, one of the costliest operational challenges is the aggressive formation of corundum deposits in their furnaces.

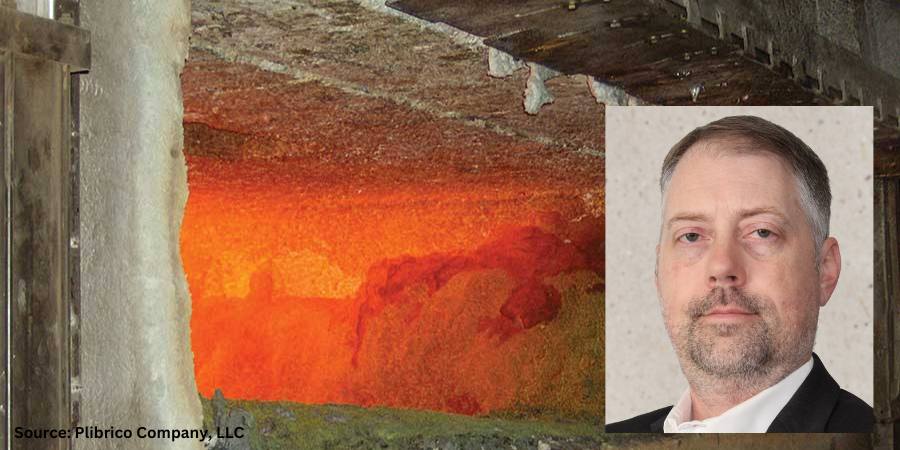

In this article, Dan Szynal, VP of Engineering & Technical Services, Plibrico, discusses the causes and concerns of corundum growth and outlines excessive, damaging, and costly corundum growth can be mitigated with the right refractory materials, coupled with the correct maintenance and watchful operation.

Root Causes of Corundum Growth

Corundum growth in a refractory lining of an aluminum furnace occurs due to a reaction between the alumina-silicate refractory and molten aluminum. Corundum formation can occur both externally and internally in the refractory lining.

There are four identifiable root causes that promote corundum growth:

- High temperature

- Presence of oxygen

- Alloy composition

- Use of fluxes and fluoride salts

High temperatures accelerate the reduction of oxides in the refractory. The higher the temperatures, the more quickly non-wetting agents lose their effectiveness. Aluminum begins to penetrate the refractory matrix because of decreases in aluminum viscosity and surface tension. Excessive furnace temperature can be the result of several causes: overfiring, improper furnace control, or inaccurate thermocouple placement. For example, a thermocouple that is recessed into the refractory lining by 2 inches may underreport temperatures by several hundred degrees.

Oxygen drives the reaction process in two ways: as an atmospheric gas, and as a reducible oxide in the refractory. Minimizing oxygen by controlling negative pressure sources such as doors, windows, and well openings reduces the potential for reaction. Proper flue sizing and burner stoichiometry also reduce excess oxygen and improve furnace energy efficiency.

Alloy composition can be a factor. Some aluminum alloys contain elements that reduce the silica as well as iron oxide, zinc oxide, and other oxides in refractories. Careful attention is necessary when choosing an appropriate refractory for more aggressive aluminum alloys to reduce the potential for reaction.

The use of fluxes and fluoride salts like cryolite Na3AlF6 in aluminum melting accelerate the reduction of oxides in the refractory. Their alkaline properties also reduce the local melt temperature of the refractory at the bellyband and then infiltrate the furnace lining. Over time, with a lack of regular maintenance, the corundum buildup will reduce furnace performance and increase aluminum loss.

Trouble Spots

The spread of corundum growth occurs most commonly in areas where its formation mechanisms of heat and oxygen are present. Typical problem areas include doors, openings, flue areas, and burner cones due to the potential for excess oxygen. Negative furnace pressure can also lead to leakage from the outside. Other common areas of formation include rear walls and bellyband areas where regular cleaning and maintenance are more difficult.

Control and Avoidance

The key to fighting corundum starts with choosing the proper refractory material for molten aluminum contact. The development of effective refractory additives that combat corundum, including non-wetting additives, dense oxide barrier formers, and pore-size reducers was pioneered by Plibrico, which includes these additives in products aimed at:

- increasing wetting resistance and reducing the potential for oxidation-reduction of the refractory (The Plicast Al-Tuff® system)

- forming a reactive layer to resist molten aluminum penetration up to 2000°F (Plibrico’s Al-Shield™ refractories)

- offering good resistance to metal slag penetration, especially in higher temperatures, and adhering well to the existing refractory for repairs (Phos-bonded castables like Plibrico’s Exo-set Uno™)

In general, PliPartner refractory contractors tell us that they find phos-bonded plastic refractories to be excellent repair materials for aluminum processors. They are usually low in free silica and nonwetting. The material bonds chemically to existing refractory, making them easier to install, and phos-bonded plastic refractories are an excellent solution for corundum growth at the bellyband.

Best Practices That Will Help

A regular maintenance plan can go a long way to increasing refractory life; a schedule is essential. A knowledgeable refractory expert with genuine experience in aluminum heat processes can help with ideal schedules and checklists.

Corundum buildup is a common concern among aluminum furnace end users. Optimally, the longevity of a furnace lining depends on best practices in refractory materials and installation methods, knowing the past refractory performance history to evaluate future performance, managing expectations of furnace production output, and monitoring regular maintenance and operation of the furnace.

These factors are measurable key performance indicators that will help decision makers design and build good refractory linings for the demanding needs of aluminum producers today. Considering these factors and balancing them according to the producers’ needs can deliver a higher-quality product for longer life.