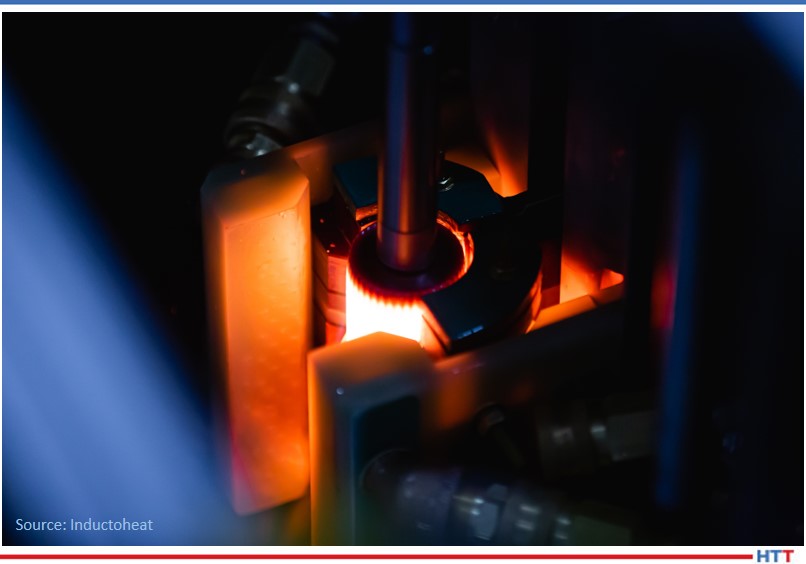

Alternatives to internal combustion engines have long dominated conversations in the automotive world. Discover why induction heating is playing a vital role in the production of the electric vehicle in this Technical Tuesday original content article written by Michael Zaharof, regional sales and marketing manager at Inductoheat.

This article first appeared in Heat Treat Today's May 2021 Induction print edition. Find the digital upload and other past editions here.

Regional Sales and Marketing Manager

Inductoheat

The electric vehicle (EV) sector of the automotive market is gaining momentum. Government mandates, fuel economy standards, and increasing consumer interest are all driving the push to EV. Some platforms are further along in the process, while others are just starting to enter the space. Many new ideas and vehicle configurations are being developed to deliver the best alternative to the internal combustion engine (ICE).

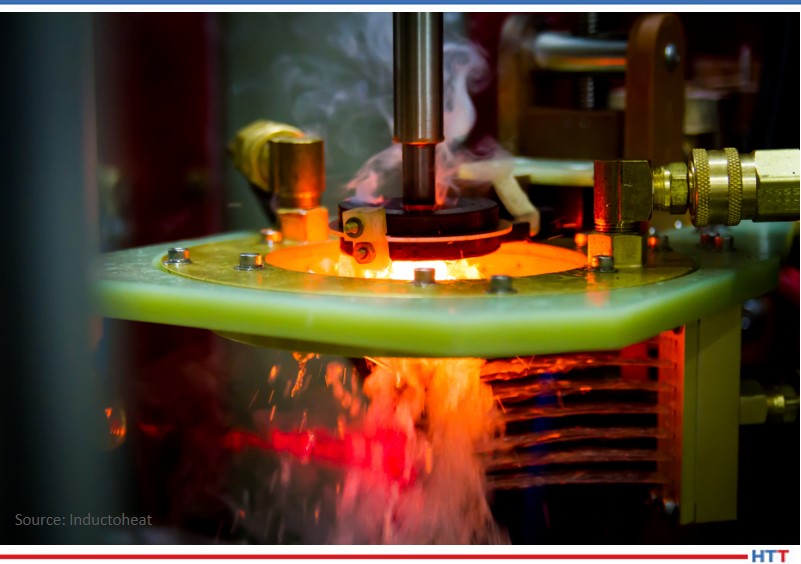

This industry is learning about the best way to configure drive mechanisms and control acceleration, be it a centralized power source operating a driveline or multiple motors powering different areas of the vehicle. Heat treating the necessary components properly to impart enough strength for the much higher torque delivery is more critical than ever compared to the traditional performance characteristics of those equipped on a standard ICE platform. Induction heating plays a critical role in the EV market as it permits several unique benefits over other thermal processing methods. Whether it is heat treating, shrink fitting, curing, or surface hardening, induction heating is one technology that has already proven itself to be beneficial for the manufacturing of electric vehicles.

Deeper Case Depth

Because of the almost instant torque delivery and fast acceleration characteristics of electric motors, EV driveline components must be more robust to handle the added torsional stresses. Combined with the need for wear resistance and fatigue life, these components must be heat treated to deliver these critical properties.

The powertrain components generally made with carbon steels (such as bearings, raceways, constant velocity joints, pinions, shafts, hubs, and gears), must be sufficiently hardened to provide enough strength, while remaining ductile enough to prevent premature failure. Induction hardening is ideal in many cases since it can deliver deeper hardened case depths, if desired, compared to other methods like conventional gas carburizing and nitriding. These alternative heat treatment methods must rely on diffusion mechanisms associated with a sustained and prolonged environment.

Alternatively, induction utilizes subsurface heating through electromagnetic current applied to a specified and customizable area achieving the desired casehardened depths. Because heat can be applied quickly to the specific area, electromagnetic induction produces much less metallurgical distortion compared to thermochemical methods that rely on through-heating and diffusion processes at high temperatures, which in some instances eliminates or diminishes the need for post heat treatment grinding or machining.

Fast & Flexible

The speed of manufacturing is an essential factor in keeping a supply chain moving and having enough product available. Many manufacturers and automotive part suppliers have adopted just in time (JIT) manufacturing workflow methodologies to increase speed to market while controlling production and inventory costs.

Induction hardening allows for parts to be processed as needed and in a way that does not require hours of processing time in contrast to alternative thermochemical heat treating methods. Because of the constant flow of individual parts and almost instantaneous time to heat, production can be incremental and consistent while still being flexible enough to adjust rates as needed. This flexibility and lean approach to inventory management can be more difficult when batches of parts are being processed together.

Also, because material distortion after induction heat treatment can be much lower, as previously mentioned, post-heat-treatment manufacturing operations can be reduced or eliminated.

Single Part Flow: Repeatability & Traceability

Part process flow is an important consideration when repeatability and traceability become essential, like in automotive manufacturing. When multiple parts are being processed simultaneously, such as in a furnace operation, individual parts cannot be validated while the heat treatment is in process. The part variability in batch operations can be impacted by part spacing, location in the furnace, gas concentration, and temperature from one batch to another.

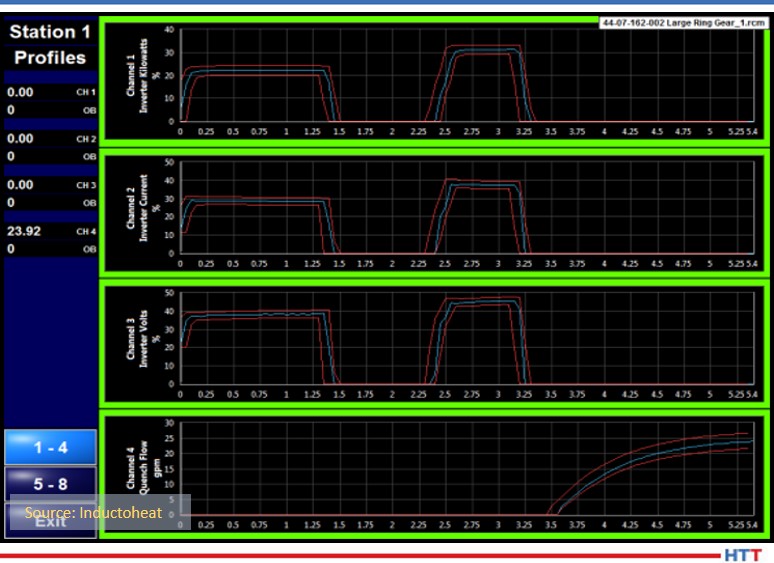

Many quality standards require tight control of the heating process and data collection during heat treatment to ensure that acceptable parts are being made. Induction heating allows precise monitoring and real-time evaluation of each stage in the heat treat process. The parameters of the process cycle – such as quench temperature, quench concentration percentage, quench pressure, quench flow, energy used, frequency, and part rotation – are just some of the points that can be analyzed by today’s sophisticated sensors and signature monitoring systems.

Some of the more advanced monitoring systems, like those offered by Inductoheat, allow the user to “teach” the induction machine what a “good part” signature looks like as all the data points of the process are plotted throughout the cycle and compared to established acceptable limits. As the process runs in production, the user can validate that all critical factors being monitored are in specification.

In the event of an issue in which one or more points are out of specification, the part will be rejected by the quality system. The cycle processing data can be instantly associated with each heattreated piece through part marking/reading or the most suitable such as radio frequency identification (RFID),u for example, for storage and later use by the manufacturer.

Environmentally Friendly

Induction heating uses electricity as its means of heat generation. Other methods such as carburizing and different batch heating processes employ gases such as ammonia and other chemicals in conjunction with fossil fuel-powered furnaces. Induction heating is considered a clean and environmentally friendly option for heattreating.

The process uses electrical energy and can quickly cycle through the desired operation and then sit idle until needed again. Most alternative systems require warm-up and cooldown time before and after production runs. In some cases, it is less expensive to keep the furnace running while continuing to burn natural resources and vent exhaust gases into the environment compared to shutting the system down in between uses.

More Efficient

Induction heating is a fast and efficient operation and can be scaled up easily to meet production requirements. Induction heating machines generally take up much less floor space than gas-powered batch furnaces. As mentioned above, they can be operated when needed without lengthy preheat or cooldown sequences.

Induction heating is associated with greater heat intensity, transferring more power directly to the workpiece in a concentrated fashion, compared to most other methods that rely on heating a surrounding environment. Induction coils can be designed to apply the required current density into an exact area of the part to be heat-treated instead of heating the entire piece.

The induction process is also more efficient as energy output can be controlled precisely to apply only the necessary power needed to obtain the desired temperature profiles at the desired production rate.

Conclusion

Induction heating is a proven and environmentally friendly process that has a long history of precision and repeatability. The ability to heat parts quickly and more effectively is why many companies have opted for induction heating over other heat treat methods. Some other popular applications utilizing induction heating employed in EV production include shrink fitting, brazing, bonding, curing, battery production, stamping, forming, and varnishing of motor components.

Induction heating technologies are also dynamic, changing every day to meet new requirements and manufacturing goals. The use of multiple power levels and frequencies from a single induction inverter is one such innovation changing how some parts are being engineered and produced. Induction heating is a solution that will continue to assist the automotive manufacturing industry for years to come.

About the Author: Michael Zaharof is a regional sales and marketing manager at Inductoheat in Madison Heights, Michigan. He has been with the company since 2011 and has worked in the sales application, digital media marketing and outside sales departments. Michael has a bachelor of computer science in Information System Security. Michael currently works with customers in several states with their induction heat treating and induction forging needs.

Contact Mike at mzaharof@inductoheat.com.