![]()

Heat treat induction coils, forgings, AM parts, and gears. What do they all have in common? R&D specialists have been creating simulations to make for more precise heat treating and solve issues like cracking or imperfect coil design. This original content piece pulls together 8 images for you on this Technical Tuesday so you can review the progress of simulation software for the heat treater over the last several years. Enjoy!

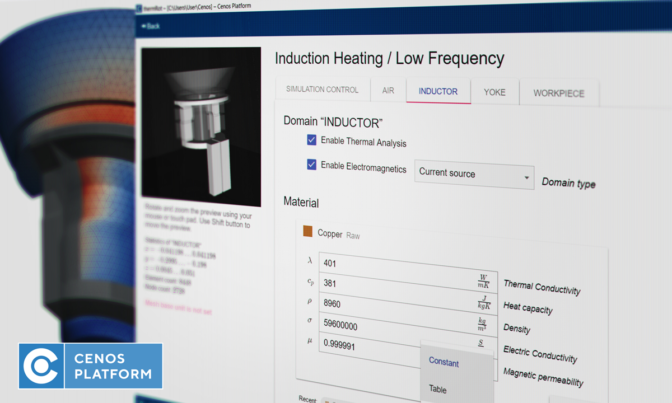

1. June 2019: Induction Heat Treatment & the Role of Simulation Software

![]() Contact us with your Reader Feedback!

Contact us with your Reader Feedback!

Looking for highly customizable induction heating solutions? Computer simulation can be the answer. Dr. Mihails Scepanskis and Dr. Vadims Geza, both of CENOS LLC, share how simulation is best employed in this summer 2019 throw back. Here's an excerpt: "Computer simulation for induction heating is a powerful tool that enables engineers to investigate or design a physical system and process using a virtual mathematical model, thus saving time and money on numerous physical design iterations."

2. September 2019: Simulation of Induction Heating of Steel Billets for Forging

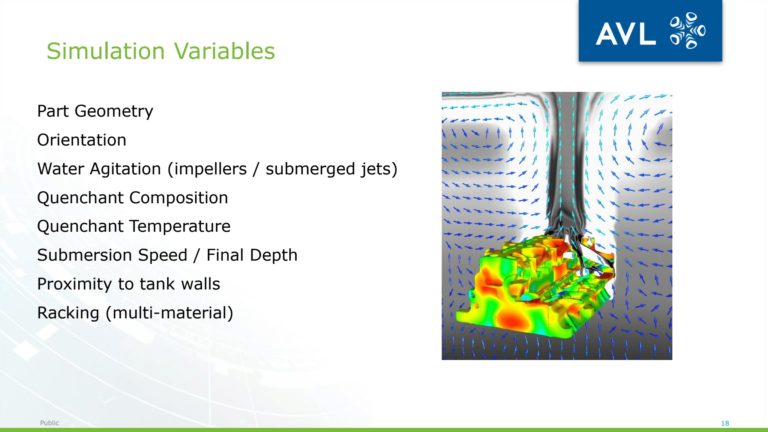

How does one go about optimizing a progressive induction heating system for a steel billet? With 3D simulation. The platform elaborated upon in this article shares how both single and multiple coil designs can be simulated as well as the material and frequency for a full experiential test.

3. November 2019: Heat Treat Radio: James Jan & Andrew Martin on Development of Modeling Software

Simulation software was also used by Ford Motor Company to solve issue of cracking in cylinder heads. This was a problem that many competitors of the automotive company also had, so figuring out a solution that would save resources, time, and money was critical. Listen to the conversation or read the transcript when you click the link above.

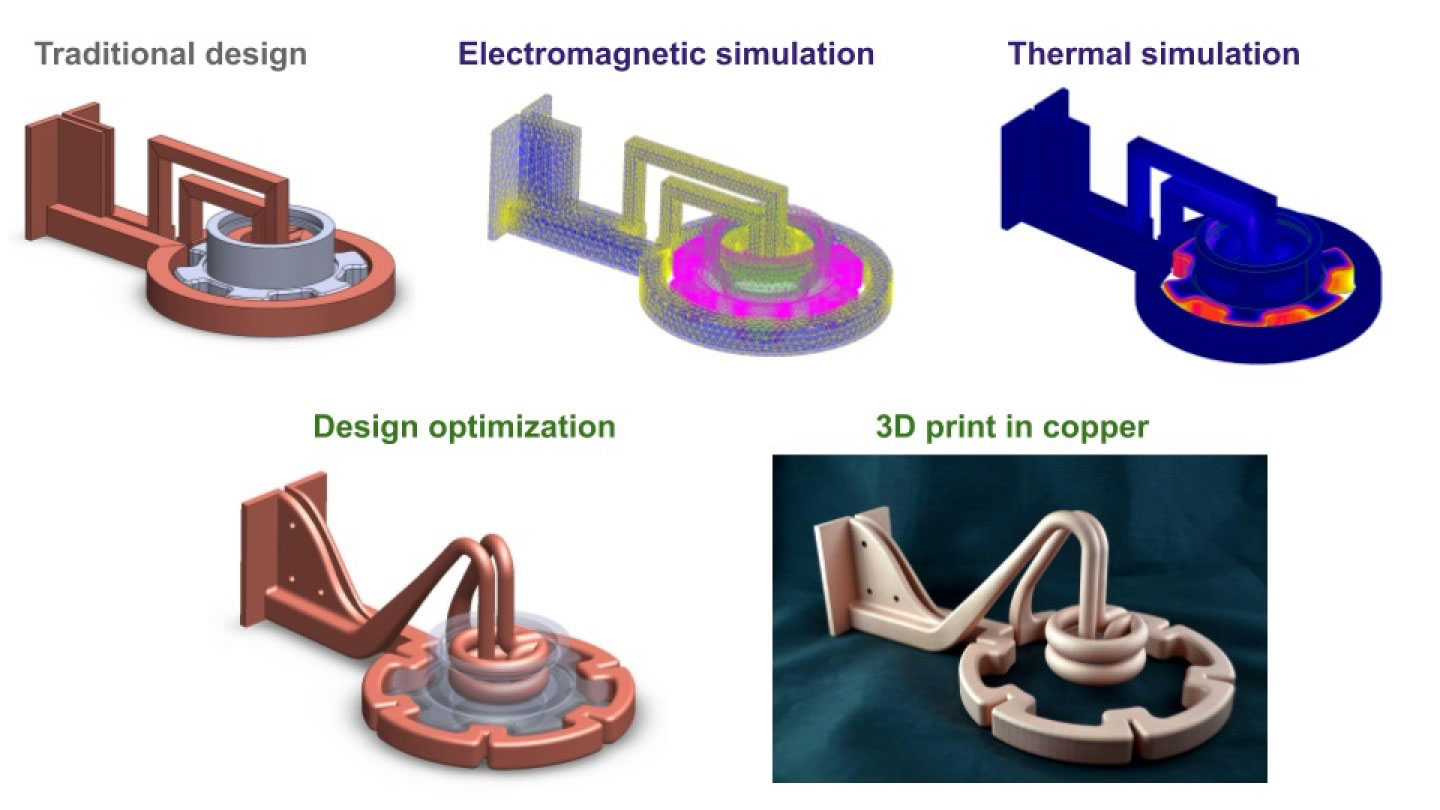

4. March 2020: Simulation Software and 3D Printers Improve Copper Coils

With additive manufacturing and especially 3D printed designs, engineers are better able to design complex parts. With part manufacturing that can solve challenging and precise problems, simulation software can help develop 3D digital prototypes to test and add extra layers of complexity. Read this article about the role of simulation in 3D printed designs.

5. June 2020: Predicting the Effects of Composition Variation for Heat Treatment of Aerospace Alloys

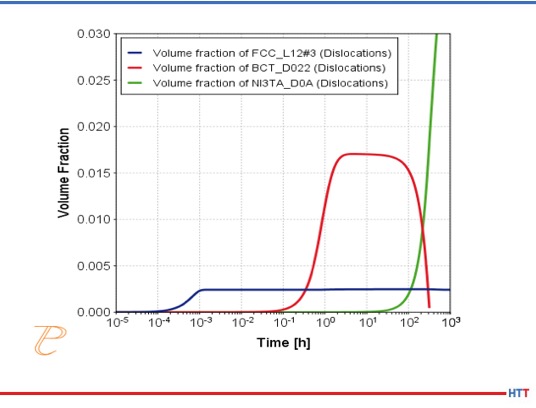

Variability between parts can mess up your heat treat operations if heat treat operators are not careful. Beyond knowing what composition is in your alloys, simulation can help predict what will happen to the different parts during heat treatment. Adam Hope and Paul Mason of Thermo-Calc Software reveal that "[the] examples shown [in this article] have illustrated how modeling and simulation tools such as those based on the CALPHAD approach can be used to predict variability arising due to material composition."

TC-PRISMA Precipitation simulations using nominal IN625 powder compositions measured at the dendrite boundaries. Recalculated based on Reference 3.

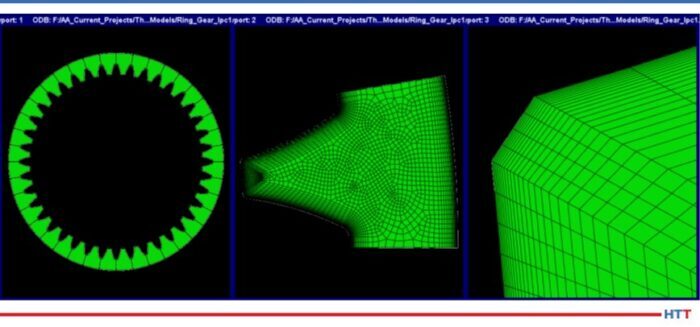

6. November 2020: Case Study: The Low-Pressure Carburizing Process Improvement for a Ring Gear

LPC got you feeling low? In this case study from DANTE Solutions, learn how the the simulation software helped a heat treater improve their LPC schedule and successfully dissolve carbides in the case of ring gears. Two of the takeaways were: "The heat treatment simulation software DANTE model parameters for carbon diffusivity, carbide formation, and carbide dissociation fit from experimental data," and "The software successfully predicted the results of a low-pressure carburizing process that was resulting in poor part performance during rolling contact fatigue."

7. January 2021: 9 Industry 4.0 Terms You Should Know

This brief reference guide will bring you up-to-speed on the Industry 4.0 terms you should know, especially as the world of manufacturing continues to rapidly change and people begin mentioning "Industry 5.0" more and more.

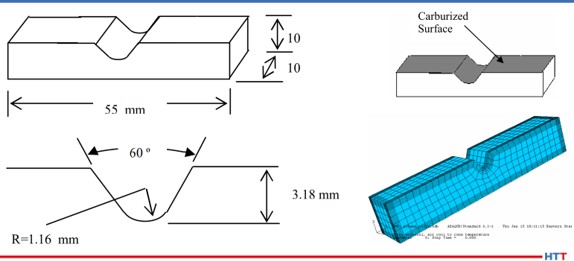

8. May and June 2021: Fatigue Improvement for Gear Steels in Helicopter Powertrains Phase 1 and Phase 2

In this two-part article series in 2021, we look at how the precise heat treating of gears can be improved with simulation software. Check it out!

Coupon dimensions, selectively carburized surface, and finite element model

Coupon dimensions, selectively carburized surface, and finite element model