Today’s News from Abroad installment is all about growth in the global heat treating market. A heat treater expands its contract machinery product line with brazing and sintering capabilities, a capital goods manufacturing group bolsters its vacuum heat treatment production capabilities, and a long-term technology alliance results in manufacturing growth of refractory products for glass melting plants in the glass industry. To round out our news from abroad, Japanese steel giants set their sights on government funding allocated to advance research and development in decarbonizing operations.

Heat Treat Today partners with two international publications to deliver the latest news, tech tips, and cutting-edge articles that will serve our audience — manufacturers with in-house heat treat. heat processing, a Vulkan-Verlag GmbHa publication, serves mostly the European and Asian heat treat markets, and Furnaces International, a Quartz Business Media publication, primarily serves the English-speaking globe.

Merger Results in Heat Treatment Furnaces Manufacturing Division

“The ECM Group is reinforcing its capital goods manufacturing business by bringing together several legal entities under the company ECM Technologies. This merger between ECM Technologies, ECM Greentech, and ECM Technologies Villard Bonnot creates a division dedicated to the manufacturing of innovative heat treatment furnaces. The aim of this merger is to better serve its customers and respond more effectively to market changes. It will enable the ECM Group to build up a veritable hub of skills and knowledge around its core areas of thermal engineering, gas management and atmospheres. This marks a first step towards realizing its ambition of becoming the world leader in vacuum heat treatment equipment, all technologies combined.”

READ MORE: “ECM Technologies merges with ECM Greentech” – at heat-processing.com

Japanese Steel Giants Pursue Government Allocated Green Funding

“Two of the largest integrated steel producers in Japan, Nippon Steel and JFE Steel, have applied for government funding allocated through the new Green Transformation Promotion Act (GX) to advance research and development in decarbonizing operations. JFE Steel is seeking funds to build a new large electric arc furnace (EAF) to replace blast furnace No. 2 at West Japan Works (Kurashiki). The company expects the EAF to be commissioned between 2027-2028. Blast Furnace No. 2 at the plant underwent a re-lining in 2003. JFE usually performs such maintenance after about 25 years of operation, so the next one is due in 2028. However, JFE Steel hopes that the new electric arc furnace will be operational by then, so the unit can be shut down. West Japan Works currently operates three blast furnaces with a steel output of about 8Mt/yr.”

READ MORE: “Japanese steel giants apply for government subsidy to go green” at furnaces-international.com

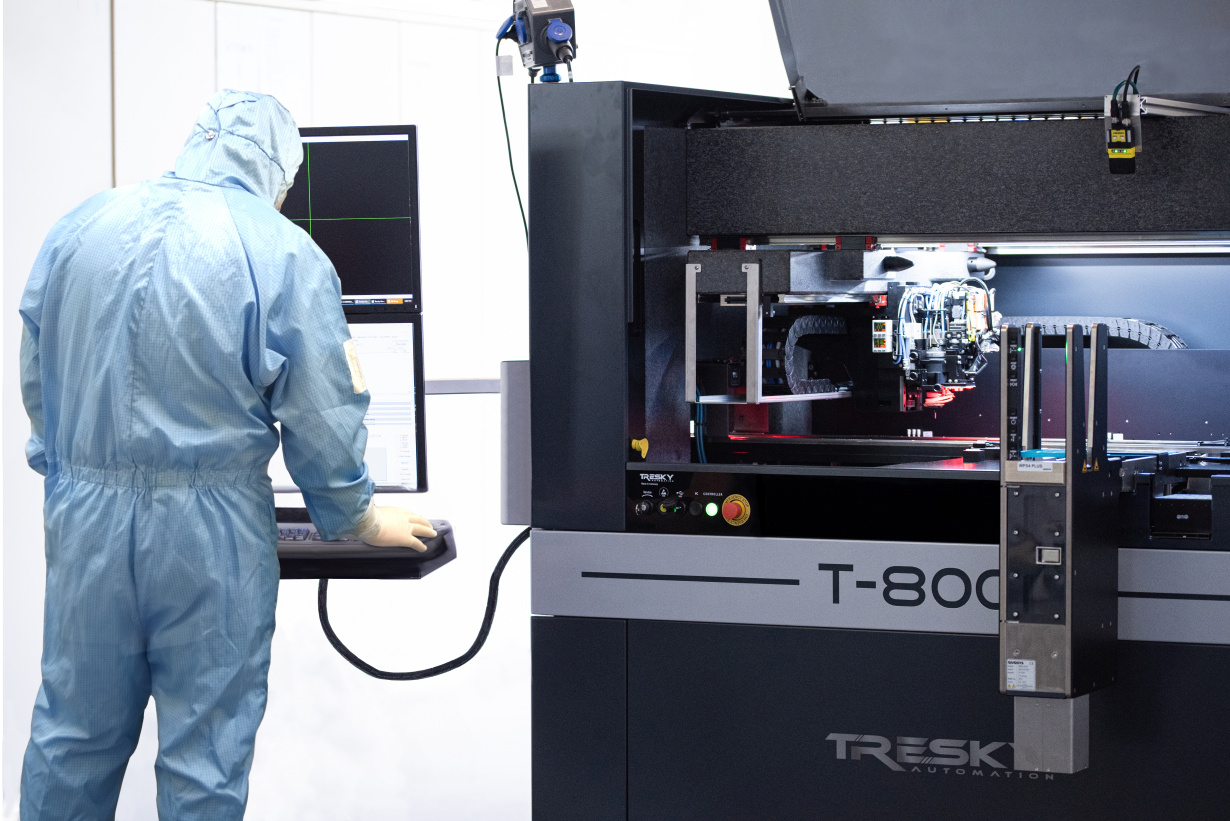

Contract Machinery Manufacturer Expands Capabilities With Vacuum Brazing Furnace, Sintering Press

“Tresky Automation announces the latest addition to its contract manufacturing machinery. Customers will now benefit from a state-of-the-art vacuum brazing furnace and a powerful sintering press with a maximum pressing force of up to 15 kN. The new equipment enables Tresky to offer additional manufacturing technologies, which is particularly beneficial for demanding applications in the fields of photonics, optoelectronics, hybrid bonding, microelectronics and power electronics. The new vacuum brazing furnace offers the possibility to produce material bonding under controlled conditions with nitrogen (N2) or formic acid (HCOOH). This process effectively reduces voids, as the vacuum allows air or process residues to escape during the preheating and melting phase of the solder. The result is virtually void- and flux-free solder joints that are characterized by high reliability.”

Technology Alliance Enables Growth in Refractory Products Manufacturing

“RATH and REFRATECHNIK announced the launch of a long-term technology alliance. The goal of the ambitious partnership is close collaboration in the development and manufacture of refractory products for glass melting plants in the glass industry. As part of the technology alliance, both companies will contribute their respective know-how in glass manufacturing and refractory production to combine it into a unique technology solution. The two companies will be operating under the name ‘R² – THE GLASS FURNACE ALLIANCE.’ The alliance enables RATH to expand its technological expertise, as products manufactured by REFRATECHNIK will be developed in close collaboration with the research and development departments of both companies.”

READ MORE: “RATH and REFRATECHNIK form technology alliance” at furnaces-international.