Processes that utilize electric-powered industrial heaters instead of fossil fuels will necessitate improved power consumption management. Therefore, advanced technologies in power management systems are critical, as in-house operations think about cost savings and electric power requirement compliance.

Janelle Coponen, senior product marketing program strategist, and Christian Schaffarra, director of research and development — Power Control Solutions’ Engineering Team, both of Advanced Energy, address the key to the discussion, SCRs and VSC, in this Technical Tuesday. Read more to understand how the reduction of harmonics allows operations to better manage energy consumption.

This informative piece was first released in Heat Treat Today’s January 2025 Technologies To Watch in Heat Treating print edition.

Processes are increasingly converting to electric-powered industrial heaters instead of fossil fuels to improve process control and comply with the latest energy policies. This transition enables greater operational efficiencies but necessitates improved power consumption management by companies and their heat treat operations.

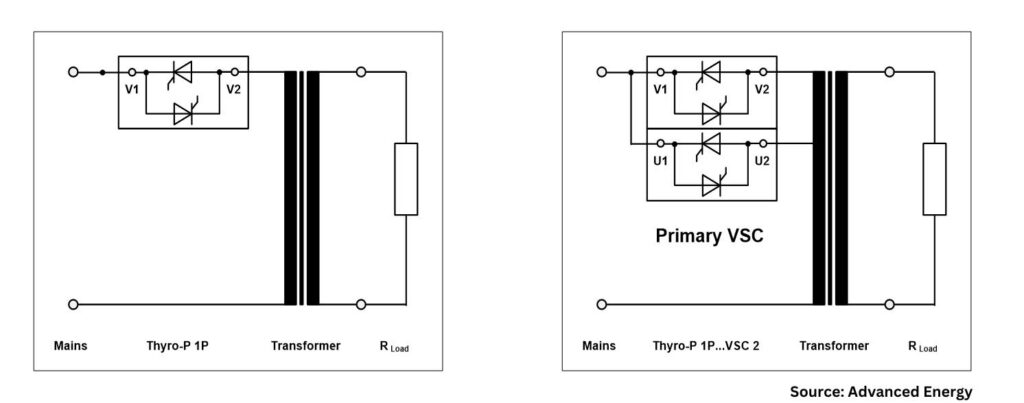

The integration of advanced technologies in power management systems is critical for both cost savings and to comply with electric power requirements. Among these technologies, silicon-controlled rectifiers (SCRs) and voltage sequence control (VSC) play a pivotal role in optimizing energy consumption. This article explores the significance of the reduction of harmonics by using a special energy-efficient mode to allow facilities to better manage and reduce their energy consumption.

What Are SCR Power Controllers?

SCR power controllers regulate the power delivered to resistive or inductive loads. Unlike traditional mechanical switches, SCRs offer faster switching times and greater reliability. They are commonly used in applications requiring heating, melting, or bending such as heating elements, motors, and lighting systems.

These devices control electrical power, current, or voltage with high precision and reproducibility. They adjust the phase angle of the AC supply, allowing for finer control over the amount of power sent to the load. This reduces energy consumption and minimizes wear on the equipment, thereby extending its lifespan. Phase-angle firing is designed for high dynamic loads with small thermal inertia and allows for high control dynamic, soft and bump-less loading, and exact current-limit setting.

SCR power controllers produce high manufacturing quality and efficiency through:

- Energy efficiency of approximately 99.6%

- Power density of approx. 18 W/in3 (for 3-step VSC SCR)

- High accuracy up to 1% for output power, 0.5% output voltage

- Flexibility

- EtherCAT Interface

Traditional SCR operation can be inefficient, especially under partial loads. An energy-efficient mode optimizes the SCR firing angle based on load requirements, reducing energy waste. By adapting to varying loads, these controllers improve system efficiency, lower energy costs, and reduce environmental impact.

Understanding Power Factor

Power factor (PF) is a critical component, representing the ratio of real load power (kW, the actual power consumed) to apparent load power (kVA, the total power supplied). It is a measure of how effectively electrical power is being converted into useful work output. A power factor of 1 (or 100%) indicates maximum efficiency, while lower values indicate wasted energy due to reactive power.

In many industrial settings, a low power factor can lead to higher electricity bills and additional charges from utility companies. Utilities must generate more power to compensate for the inefficiencies caused by reactive power, which does not perform useful work.

Benefits of Improved Power Factor and Reduced Harmonics

One significant advantage of using SCR power controllers is the ability to minimize harmonic distortion. Harmonics are voltage or current waveforms that deviate from the ideal sinusoidal wave, often caused by non-linear loads like electronic devices. These distortions can lead to overheating, equipment damage, and inefficiencies within the electrical system.

Reducing harmonics improves the overall efficiency of power systems and smoother equipment operation, which can prevent costly downtime. Additionally, improving power factor can result in financial savings by reducing energy loss, lowering demand charges, and increasing the capacity of existing electrical infrastructure.

This results in lower energy bills, less wasted energy, and better system reliability. Improved power factor can also help meet regulatory standards requiring specific power factor levels.

Special Energy-Efficient Mode, Voltage Sequence Control (VSC)

VSC complements SCR technology to enhance power system performance by managing voltage levels more effectively. It systematically sequences voltage application to loads, which improves power quality and extends the lifespan of equipment.

VSC is particularly beneficial for applications with inductive loads, where voltage management can significantly reduce inrush currents and mitigate harmonics. By integrating VSC with SCR technology, industries can harness the benefits of both systems, ensuring a stable and efficient power supply.

Combined Advantages of SCRs with Voltage Sequence Control

- Improved energy efficiency: By optimizing firing angles and managing voltage sequences, facilities can achieve substantial reductions in energy consumption.

- Cost savings: Lower energy usage translates directly into reduced operational costs, making these technologies economically attractive for businesses.

- Enhanced equipment longevity: By reducing stress on electrical components through better voltage management, both SCRs and VSC can prolong the operational lifespan of machinery.

- Environmental impact: Energy-efficient systems contribute to lower greenhouse gas emissions, aligning with global sustainability goals and regulatory standards.

Advantages and Disadvantages of Using SCR in Voltage Sequence Control Mode

Here are several of the advantages:

- Improved stability: Helps maintain voltage stability across the system, reducing the risk of voltage fluctuations and outages.

- Enhanced performance: Optimizes the performance of electrical equipment by ensuring they operate within their rated voltage range, improving efficiency.

- Protection against voltage imbalances: Monitors and adjusts for voltage imbalances in three-phase systems, which can prevent equipment damage and reduce wear.

- Energy efficiency: By maintaining optimal voltage levels, VSC can lead to energy savings and lower operational costs.

- Automated control: Often incorporates automation, allowing for real-time adjustments without manual intervention, thus improving response times.

- Lowest level of harmonics: VSCs can help minimize harmonic distortion in electrical systems.

- Lowest level of reactive power: The specific control design of the VSC can significantly impact the minimum achievable reactive power level, even in a weak grid.

Compare with a few disadvantages:

- Large footprint: Larger power controller footprint versus standard SCR power control system.

- Initial cost: The initial investment in VSC systems and related technology can be higher, but payback time is less than a year.

Conclusion

In-house heat treat operations aiming for greater efficiency and cost reduction can benefit from VSC, the energy-efficient mode for SCR power controllers. By enhancing power factor and reducing harmonics, these devices optimize energy use and support sustainable, cost-effective operations. Adopting such technologies leads to significant improvements in industrial power consumption and enhanced savings for end users.

About the Author:

Senior Product Marketing Program Strategist

Advanced Energy

With more than 21 years of experience in the industrial and energy sectors, Janelle Coponen bridges the gap between technical solutions and market needs. At Advanced Energy, she works alongside engineering teams to translate complex technologies into market ready strategies ensuring alignment between engineering innovations and business objectives.

For more information: Contact Janelle at Janelle.Coponen@aei.com.

Director of Research and Development

Power Control Solutions’ Engineering Team

Advanced Energy

With more than 30 years of experience, Christian Schaffarra leads a research team dedicated to developing and advancing innovative power control technologies, ensuring optimal performance and reliability. He has a deep understanding of both the technical and marketing requirements that drive successful product development and engineered solutions.