A global manufacturer of aircraft parts has ordered a single-chamber vacuum furnace for brazing jet engine parts. The new equipment will replace a 30-year-old unit previously operating in its Poland-based plant.

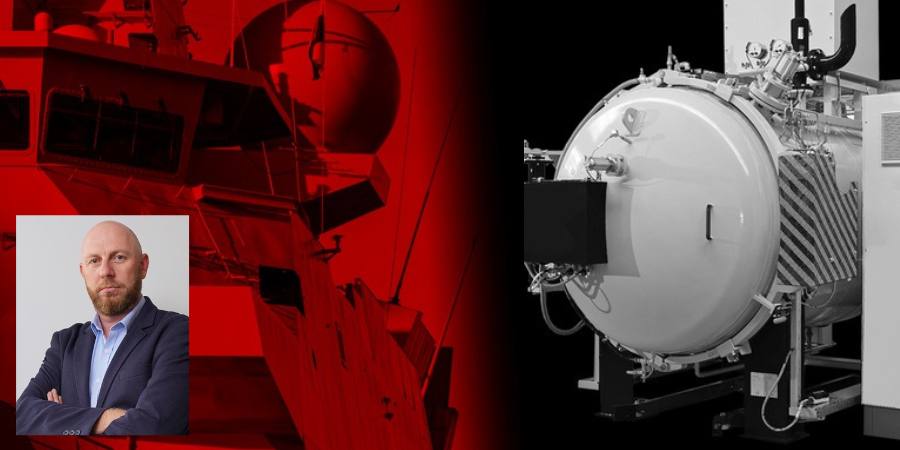

Sales Manager

SECO/WARWICK Group

Source: LinkedIn

The new Vector® vacuum furnace is being supplied by SECO/WARWICK, which also manufactured the retiring equipment. The upgrade is based on a standard Vector vacuum furnace with a working space of 900 x 900 x 1200 mm, with screen insulation and metal heating elements. The solution has been adapted to industry specific needs and can heat treat jet engine components, such as complex gears or main shafts.

“This unit is distinguished by the ability to carry out efficient and clean high vacuum processes thanks to the use of a molybdenum heating chamber and a very efficient pumping system. This ensures very high purity and the dynamics required for brazing processes. Another big advantage is the very good temperature uniformity in the molybdenum heating chamber and compliance with the strict requirements of industry standards such as AMS2750,” said Jędrzej Malinowski, sales manager, SECO/WARWICK Group.

The press release is available in its original form here.