Castool Heat Treat Capabilities Expand with Nitrocarburizing

Castool Tooling Systems, a tooling provider to extrusion and die-casting companies, expanded its in-house capabilities with a nitrocarburizing system.

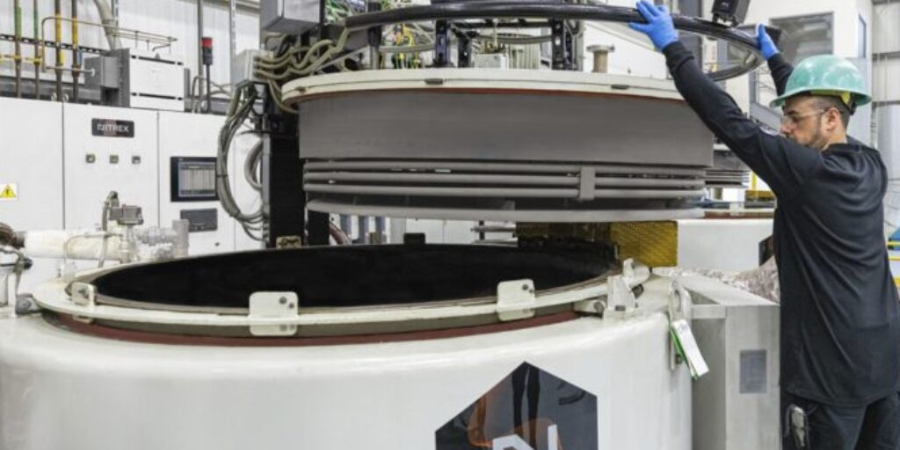

The new pit-type nitrocarburizing furnace, a model NX-1625 from Nitrex, is capable of processing large workloads of up to 6000 kg (13,200 lb.) with dimensions of 1550 mm (61”) in diameter and 2500 mm (98.5”) in height. The turnkey solution includes Nitreg®-C controlled nitrocarburizing and ONC® post-oxidation technologies, which can treat shot sleeves made of H13 tool steel while improving strength and longevity and preventing distortion when used in high-temperature and corrosive environments.

Account Manager

Nitrex

Source: NITREX

Commenting on the recent nitrocarburizing furnace, Nikola Dzepina, account manager at Nitrex, notes, "[Castool, a division of Exco Technologies] have been outsourcing nitriding to our heat treating services for many years and have been impressed with the quality of service and customer experience."

The large capacity furnace is part of a significant investment project that saw several furnace OEM suppliers collaborating to outfit the New Market, Canada, facility with various pieces of heat treating process equipment.

Find heat treating products and services when you search on Heat Treat Buyer's Guide.com

Castool Heat Treat Capabilities Expand with Nitrocarburizing Read More »