Aero and Turbine Heat Treat Expands for Titanium Steel Castings Manufacturer

![]()

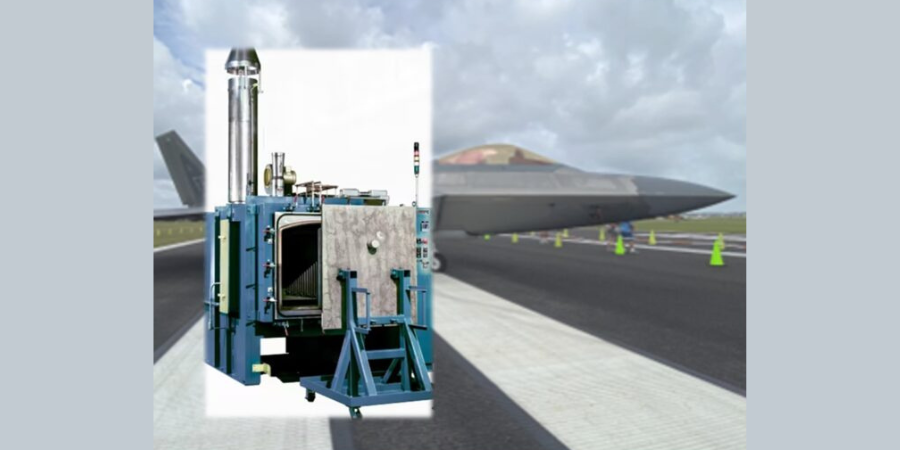

A front-loading box furnace delivered to a northeastern U.S. supplier of titanium castings will expand the manufacturer’s aerospace and gas turbine castings heat treat abilities. The company supplies to the aerospace and power generation fields and deals with exotic metals that are ideal for superior products using the lost wax process for castings, such as nickel and cobalt-based alloys.

Source: L&L Special Furnace Co., Inc.

The L&L Special Furnace Co., Inc. model FB435 has an effective work area of 48” wide by 32” tall by 60” deep and has certifiable temperature uniformity of ±10°F from 500 to 1,850°F. Additionally, the elements are very evenly spaced around the chamber and the furnace is lined with ceramic fiber on the sides and top.

The furnace case is sealed internally for atmosphere control, and an inert blanketing gas such as nitrogen is used to displace oxygen present within the work chamber. This provides a surface finish in which oxidization is less likely to form on the part. The atmosphere is delivered automatically through a flow panel by the furnace control.

Find heat treating products and services when you search on Heat Treat Buyers Guide.com

Find heat treating products and services when you search on Heat Treat Buyers Guide.com

Aero and Turbine Heat Treat Expands for Titanium Steel Castings Manufacturer Read More »