Thermomechanical Processing for Creating Bi-Metal Bearing Bushings

Multi-material design aiming at application-optimized technical components has been gaining importance over the last several years. In this context, combining steel and aluminum offers an effective solution for implementation of lightweight concepts due to its high strength-to-weight ratio. Due to the dissimilar material properties of steel and aluminum, the process design for bi-metal forming is very challenging and requires a process-specific heating strategy, the development of which is the focus of this paper, originally presented at IFHTSE TPIM 18 in Spartanburg, South Carolina. The current study involves the potential for creating bi-metal bearing bushings consisting of steel 20MnCr5 and aluminum AA-6082 by closed-die forging.

Multi-material design aiming at application-optimized technical components has been gaining importance over the last several years. In this context, combining steel and aluminum offers an effective solution for implementation of lightweight concepts due to its high strength-to-weight ratio. Due to the dissimilar material properties of steel and aluminum, the process design for bi-metal forming is very challenging and requires a process-specific heating strategy, the development of which is the focus of this paper, originally presented at IFHTSE TPIM 18 in Spartanburg, South Carolina. The current study involves the potential for creating bi-metal bearing bushings consisting of steel 20MnCr5 and aluminum AA-6082 by closed-die forging.

This article by Bernd-Arno Behrens, Robert Goldstein, and Anna Chugreeva originally appeared in Heat Treat Today’s June 2019 Automotive Print Issue.

Introduction

The world-wide competition in the transportation industry has awakened in manufacturers a growing interest in developing cost-effective and environment-friendly technologies reducing fuel consumption. This trend results in increasing demands on technical components and requires production of high-performance components with advanced functionality and weight reduction. Conventional materials cannot satisfy all these requirements due to material-specific limitations.

Multi-material designs afford the opportunity to place the appropriate material at the appropriate location with regard to individual operational conditions. When combining the benefits of different materials in a single component, it is possible to create application-optimized parts with a significant weight reduction while maintaining high durability and performance.

In this context, combinations of dissimilar materials, such as steel and aluminum, are becoming increasingly important for research and development. However, the forming of steel-aluminum components is rather challenging due to the various thermo-physical properties of each material. Most challenging is the fact that the forming temperature of steel significantly exceeds the melting point of aluminum. In order to achieve correct material flow and complete die filling, specific heating strategies are necessary to create the appropriate temperature gradients between different regions in the component.

The current study introduces a method to produce bi-metal bearing bushings by closed-die forging. The overarching goal was to examine the feasibility of this approach for bi-metal forming and to establish the effect of the thermomechanical processing during heating and forming on the bond quality. To study the process, bi-metal workpieces joined by shrink fitting were used. In order to define the temperature distribution appropriated for the subsequent forming, the induction heating process was investigated by modeling and experimentation. Besides the achieved temperature gradients used for the forging experiments, forged bearing bushings, and results regarding material flow, microstructure and the bonding zone are demonstrated. Additional considerations are given on how to further improve the process and achieve production capabilities.

State of the Art

At the industrial scale, multi-material machine components (i.e. brake discs, hydraulic cylinder rods, valves, shafts, etc.) are commonly fabricated by joining two individual components that are already given their near-final or final form. An alternative solution is represented by the bulk metal forming of multi-material components, where forming and joining can be combined within a single-process step.

In recent years, joining by plastic forming was studied in several research works. Plancak et al. performed analytical and experimental compression tests on co-axial bi-metallic workpieces consisting of two different steel materials (C15E/C45E) in order to investigate load characteristics during the forming depending on different upset ratios [1]. Sun et al. investigated the metallurgical bonding process of bimetallic hot deformation and influence of process parameter on the diffusion behavior of different elements [2]. The compression tests were conducted under isothermal conditions using a serially arranged combination of a carbon steel Q235 and a stainless steel 316L.

The study showed that element diffusion distance in the interface zone increases with effective strain, temperature, and time during both forming and holding stages to different degrees. Behrens et al. studied compound forming of bi-material shafts by indirect impact extrusion of different steel combinations such as a structural steel S355J and a heat-treatable steel 42MoCr4 [3]. Tensile tests of bi-material specimens showed that a failure is located outside of the joining zone, which indicates a good bonding quality between materials after forming. The results were transferred to the precision forging of bi-metal spur gears with different diameters of core material and various thickness of wear-resistant ring materials.

Politis, et al. presented compound forging of gears made of dissimilar material combinations utilizing steel or copper on the outer diameter and aluminum, copper, or lead for the inner core [4, 5]. Äyer used a numerical and experimental approach for upsetting bi-metallic hollow cylinders made of copper and aluminum in order to investigate the material flow behavior during the forming [6]. A similar research work was carried out by Misirli et al. on bi-metal workpieces consisting of a steel outer ring (AISI 102) and brass or copper inner cylinder [7]. Kong et al. investigated manufacturing steel-aluminum compounds (AISI 316L/6063) by forge welding with various process parameters including temperature, amount of diameter, and forging speed. It was established that the forming temperature has the most decisive influence on the resulting quality and the tensile strength of the joint [8].

Wohletz and Groche elaborated a joining process by combined forward and cup extrusion and compared the joining of steel C15 and aluminum AW 6082 T6 at ambient and elevated temperatures [9]. It could be stated that while elevated forming temperatures have a positive impact on the final bonding quality, it is negatively affected by the emerging oxide scale that grows with increasing temperature. Kosch and Behrens investigated the compound forging of hybrid workpieces in the context of non-uniform temperature distribution between steel and aluminum raw parts and its influence on the emerging intermetallic phases [10]. Chavdar, Goldstein et al. used tailored heating strategies for hot forging and hot hydroforging of aluminum workpieces fully encapsulated within a steel shell, where the aluminum core was formed in a semi-solid or completely molten state [11, 12].

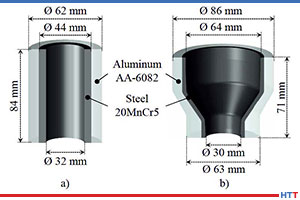

Initial and Final Geometries

The current study deals with manufacturing of a bearing bushing consisting of steel 20MnCr5 on the internal diameter and aluminum AA-6082 on the external diameter. The inner rolling surface is exposed to high stresses due to bearing balls and requires an application of high performance and wear resistant material such as steel. Removed from the high-stressed regions, lightweight materials with high toughness, ductility, and breaking resistance such as aluminum can be used for reducing the total weight of the part. The coaxially arranged bi-metal workpieces were designed in accordance with the stress conditions operating in the final parts. In this study, two concentric cylinders were joined together by shrink fitting and subsequently formed to the final geometry. The models of investigated bi-metal workpieces and bearing bushings are presented in Fig. 1.

Induction Heating Strategy

In order to achieve sufficient formability, the bi-metal workpieces have to be heated up to material-specific forming temperatures. For this purpose, a tailored heating strategy with radially inhomogeneous temperature distribution is required. For forming without cracks or other material defects, the warm or hot working temperature range (greater than 1292°F [700°C]) should be obtained in steel. At the same time, the aluminum temperature is limited to the melting onset (solidus temperature) at approximately 1076°F (580°C). Reaching required temperature gradient within the bi-material workpieces is possible using induction heating.

Induction heating is a volumetric heating method where power is controllable along the surface and in the depth of the workpiece. With the appropriate coil design and proper selection of frequency, it is possible to deposit electrical energy into the steel component with almost no direct inductive heating of the aluminum component. Using induction heating, the heating process can be tailored to achieve different temperature gradients in the composite structure to optimize the forming process [13].

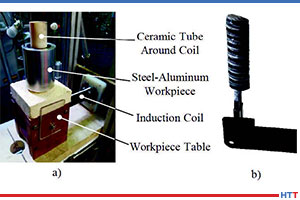

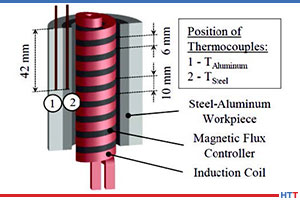

According to the geometry shown in Figure 1, an induction heating concept with a water-cooled inner induction coil and magnetic flux controller was designed (Fig. 2). With this construction, the eddy currents are primarily induced in the inner periphery of the workpiece, which leads to a more pronounced heating of the inner steel ring compared with the aluminum. The heating of the aluminum outer ring is due to conductive heat transfer from steel to aluminum.

For experimental heating tests, a middle-frequency generator Huettinger TruHeat MF 3040 with a frequency range between 5 and 30 kHz and a maximum output power of 40 kW was used. The induction coil was connected to the capacitor box with total capacity of 47.1 μF included in an oscillating circuit.

The heating process was controlled with set value presetting via percentage of the maximum voltage (300 V). For achieving the largest possible temperature difference between steel and aluminum in a short time, all tests were carried out at 100% voltage with various heating times. The maximal operating frequency was approximately 16.5 kHz. During the heating tests, time-temperature curves were recorded for the reference points in the middle of steel and aluminum rings, which are shown schematically in Fig. 3. For the measurements, mineral insulated NiCr-Ni thermocouples (Type K) with an Ø 1.5 mm stainless steel sheath were used.

In order to complement the experimental temperature values and to predict radial temperature distribution after the heating and transportation time, the induction heating process was modeled using the electromagnetic and thermal analysis software ELTATM. The main challenge of bi-metal heating modeling is to identify the thermal contact properties between steel and aluminum, which have a significant effect on the resulting temperature gradients. For this reason, the simulated thermal behavior should be matched to the experimental data [11, 12].

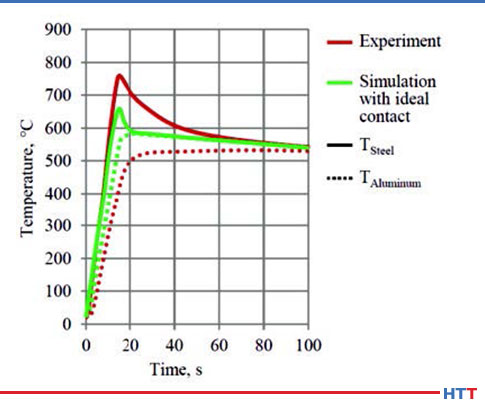

In Fig. 4, the experimental temperature curves for the heating time of 14 s are compared with simulated results under ideal thermal contact condition between steel and aluminum. In both cases, the curves equalize at the same temperature, which means that the heating was performed based on the same total energy input. More efficient contact provides for faster equalization of temperatures, which can be explained by higher heat conduction from steel to aluminum. Under real-life conditions, the connection in bi-metal workpieces without metallurgical bonding is not perfect. This results in significantly less heat transfer and slower heating of the aluminum ring. Therefore, the temperature equalization takes a longer time in workpieces produced by shrink fitting. In this case, a higher temperature gradient between steel and aluminum is favorable for the subsequent forming process.

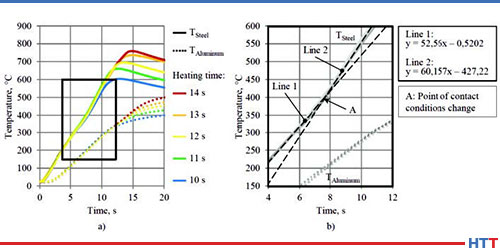

It should be taken into account that the contact characteristics between steel and aluminum are not constant over the heating time. Due to different thermal expansion of steel and aluminum, the gap between the materials grows with increasing temperatures. This behavior can be proven by experimental investigations. Fig. 5a shows the temperature curves with various heating time (from 10 up to 14 s). The resulting absolute temperatures and temperature gradients between steel and aluminum are different, but the initial heating process is reproducible for all of the tests.

In Fig. 5b, it can be seen that the temperature curves for steel have a slight bend at the same point, when the steel temperature (approximately 752°F [400°C]) is about two times higher than the aluminum temperature (approximately 392°F [200°C]). Higher heating rates of steel after this point can be explained by lower thermal conduction from steel to aluminum due to increasing gap size between steel and aluminum parts. This effect should be considered by modeling of the heating process.

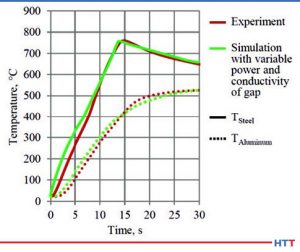

In order to reproduce this phenomenon in heating simulation, a thin layer with temperature dependent conduction properties was integrated in bi-metal workpieces between steel and aluminum [11, 12]. The temperature curves received with the validated model are shown in Fig. 6. They agree with the experimentally measured temperatures. The slight deviation at the beginning and the end of the heating process can be explained by thermal lag of the thermocouples because of relatively greater diameter of their steel sheath.

Forging Process

Forging processes represent a promising method for forming bi-metals due to several benefits, such as outstanding material properties, uninterrupted grain flow, and homogeneous structure. Moreover, forging at elevated temperatures enables reaching high strains and forming complex geometries in a single stroke. Additionally, thermal and mechanical influence during the forging can lead to improving local mechanical properties and the quality of the resulting joining zone.

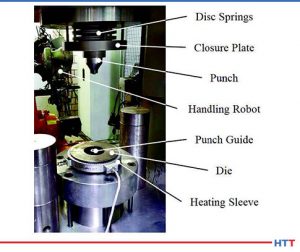

For manufacturing bearing bushings from bi-metal hollow workpieces, a single-step forging process was designed. The forming is performed in a closed-die forging system, which is presented in Fig. 7. Within the forging stage, the material is formed by two active tool components—a punch and a closure plate. While the upper punch gives the inner shape of the bushing, the closure plate attached to the moving frame by a set of disc springs ensures the final height of the forgings. At the end of the forming process, the forged bushing is automatically detached from the upper punch with the force stored in the disk spring stacks. A hollow ejector system then removes the final bearing bushings from the forging die.

Before the forming process, the warm workpieces are automatically transferred from the induction heating unit to the forming tool by means of a programmable robot arm to ensure high reproducibility and to limit heat exchange during transportation. The transportation time was limited to 6 s for all of the forging tests. After the forging, the final parts are cooled down by air.

Results and Discussion Temperature Distribution

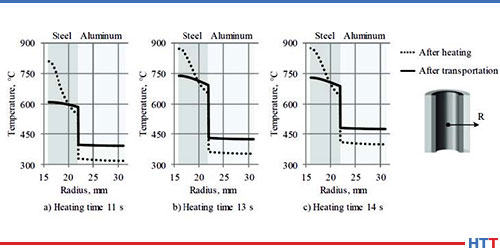

The maximum heating time during the experimental investigations was limited to 14 s. With increasing heating time, the temperature of steel and aluminum equalizes above the solidus temperature, which leads to the partial melting of aluminum. Fig. 8 represents the temperature evolution for three heating strategies (a, b, and c) with various heating times. The diagrams show the radial temperature distribution directly after heating and transportation time. The temperature profiles after the transportation corresponding with the forming temperature are of great importance for the following forming process. In strategy a (Fig. 8, left), the steel shows the lowest temperature and thus will have reduced formability compared with other heating strategies. At the same time, the heating strategy b (Fig. 8, middle) leads to the largest temperature gradient between the steel and aluminum and thus is the most suitable for subsequent forging. The final temperature of steel is between 1292-1382°F (700-750°C) and the temperature of aluminum is about 806°F (430°C). With heating strategy c (Fig. 8, right), similar steel temperature has been achieved, although the entire heating phase was longer in this case. With this strategy, the aluminum is heated to a higher temperature of approximately 896°F (480°C) after transportation due to its high thermal conductivity, and thus a lower temperature gradient compared with strategy b can be achieved.

Forged Bearing Bushings

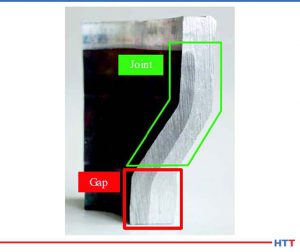

Based on conducted investigations, heating strategy b with heating time of 13s and transportation time of 6s has been primarily used for the subsequent forming tests. The bearing bushing forged using the selected heating strategy is presented in Fig. 9.

Due to the lower flow stress, aluminum flows over the steel and forms an undercut in the upper part of the bearing bushing. The steel in the upper part undergoes a high radial expansion leading to a wall thickness reduction from 6 to 5 mm. In contrast to this, the wall thickness of the steel part is increased up to 7 mm in the bottom area, possibly due to axial up-setting. As observed in Fig. 9, the bearing bushing exhibits a sufficient macroscopic form fit between the steel and aluminum part. For detailed characterization of bonding quality, the specimens extracted from the forged bearing bushings were metallographically investigated. The metallographic cuts with resulting joining zone are presented in Fig. 10.

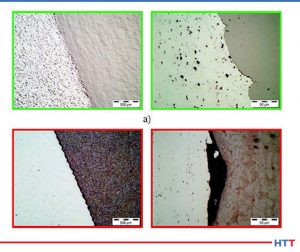

In general, two zones with different bond quality can be indicated as shown in Fig. 9 (green, red). In the upper area, a form- and force-closed joint has been achieved (Fig. 10a, left). In addition, a wavy topography from the finishing process can be observed in a higher magnification (Fig. 10a, right). In the bottom area, an undesired separation was detected (Fig. 10b, left). Due to the similar topography of both materials in some areas of the interface zone, it can be assumed that the separation is partially caused by shrinkage during the cooling process. A maximal gap size of approximately 40 μm was measured (Fig. 10, right).

Conclusions and Outlook

The presented work focuses on the issues occurring during the forming of bi-metal components. In this case, employed heating strategy becomes a key tool to control temperature distributions in the component, which are critical in efforts to achieve appropriate material flow during the forming process. In this context, a process for production of steel-aluminum bearing bushing, including the FE-aided development of a reliable inductive heating strategy, has been designed. The feasibility of the developed methods has been successfully validated with an experimental forging study. Metallurgical evaluations were conducted on the formed bi-metal components.

The metallurgical studies showed good bonding was achieved with both the form- and force-closed joint in the areas with high deformation. In the bottom area of the bearing bushing, where the material is less deformed, the resulting bond quality was poor. Thus, the forming process (e.g. punch geometry) or the heating strategy (higher temperature gradients by changing the input power) needs to be improved to ensure sufficient bonding over the entire joint zone.

Metallurgically bonded bi-metal blanks produced by coaxial lateral extrusion will be employed in further investigations. Thus, the materials will be joined prior to forming, which should have a further positive impact on the resulting joint quality. However, due to improved contact between the workpieces, higher power from the induction heating power supply would be beneficial in achieving the desired temperature gradients.

Acknowledgements

The results presented in this paper were obtained within the Collaborative Research Centre 1153 “Process chain to produce hybrid high-performance components by Tailored Forming” in subproject B2. The authors would like to thank the German Research Foundation (DFG) for the financial and organizational support of this project.

About the Authors

Bernd-Arno Behrens is the Director of the Institute of Forming Technology and Machines (IFUM), Leibniz Universitat Hannover, Germany. Robert Goldstein is the Director of Engineering with Fluxtrol, Inc. Anna Chugreeva is a Research Associate with the Institute of Forming Technology and Machines (IFUM), Leibniz Universitat Hannover, Germany. This article originally appeared in Heat Treat Today’s June 2019 Automotive Print Issue and is published here with the authors’ permission.

References

[1] Plancak, M., et al., “Compression of bimetallic components-analytical and experimental investigation,” Annals of the Faculty of Engineering Hunedoara, Vol. 10, No. 2 (2012), pp. 157-160.

[2] Sun C. Y. et al., “Element diffusion model of bimetallic hot deformation in metallurgical bonding process,” Materials & Design, Vol. 94 (2016), pp. 433-443.

[3] Behrens, B.-A., et al., “Investigation of load adapted gears and shafts manufactured by compound-forging,” Journal of Advanced Manufacturing Systems, Vol. 7, No. 1 (2008), pp. 175-182.

[4] Politis, D. J., et al., “An investigation into the forging of Bi-metal gears,” Journal of Materials Processing Technology, Vol. 214, No. 11 (2014), pp. 2248-2260.

[5] Politis, D. J., et al., “Investigation of material flow in forging bi-metal components,” Proceedings of the 14th International Conference on Metal Forming, January 2012, pp. 231-234.

[6] Ayer, Ö., “Material flow analysis of bimetallic hollow disc upsetting,” 6th International Conference on Trends in Agricultural Engineering, September 2016, Prague, pp. 38-43.

[7] Misirli, C., et al., “Experimental and fem study of open die forging for bimetallic cylindrical parts produced using different materials,” International Journal of Modern Manufacturing Technologies, Vol. 8, No. 1 (2016), pp. 69-74.

[8] Kong, T. F., et al., “Experimental Study of Effects of Process Parameters in Forge-Welding Bimetallic Materials: AISI 316L Stainless Steel and 6063 Aluminium Alloy,” Strain, Vol. 45, No. 4 (2009), pp. 373-379.

[9] Wohletz, S. and Groche, P., “Temperature Influence on Bond Formation in Multi-material Joining by Forging,” Procedia Engineering, Vol. 81 (2014), pp. 2000-2005.[10]Kosch, K.-G. and Behrens, B.-A., “Challenges in Compound Forging of Steel-Aluminum Parts,” EPD Congress 2011, John Wiley & Sons, Inc., pp. 169-176.[11]Chavdar, B., Goldstein, R., et al., “Hot Hydroforging for Lightweighting,” IDE 2015; Bremen, Germany; Sep. 23-25, Vol. 5, pp. 117-128.

[12] Goldstein, R., et al., “Modeling of the Heating Sequences of Lightweight Steel/Aluminum Bimaterial Billets for Hot Forging and Hot Hydroforging,” 23rd IFHTSE Congress, pp. 18-22.

[13] Abrikosov, A. A., Fundamentals of the Theory of Metals, Vol.1, North-Holland (Amsterdam, 1988).

Thermomechanical Processing for Creating Bi-Metal Bearing Bushings Read More »