Dig into the Archives: 5 Technical Articles for Fresh Heat Treaters in Auto

![]() Are you a relatively new reader in automotive heat treat? Welcome. Enjoy this archive of articles from the automotive industry, which provides years of technical knowledge to fill any information gaps. Even the "OG" readers with Heat Treat Today will want to investigate this Technical Tuesday original content compilation that plumbs the depths of the archives.

Are you a relatively new reader in automotive heat treat? Welcome. Enjoy this archive of articles from the automotive industry, which provides years of technical knowledge to fill any information gaps. Even the "OG" readers with Heat Treat Today will want to investigate this Technical Tuesday original content compilation that plumbs the depths of the archives.

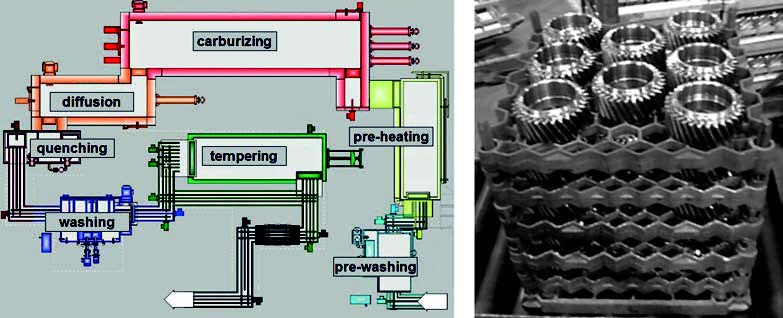

1. What Heat Treatment To Use for Truck Gear Boxes?

This paper reveals the investigation and conclusions of distortion potentials for case hardening processes. Mainly, the focus was on how the SyncroTherm® concept method compared to conventional case-hardening processes for gears and sliding sleeves.

This paper reveals the investigation and conclusions of distortion potentials for case hardening processes. Mainly, the focus was on how the SyncroTherm® concept method compared to conventional case-hardening processes for gears and sliding sleeves.

Read about how the results effected the bottom line: reduced costs, quicker processes, and less distortion. Also, be sure to examine each of the charts and figures for further understanding of each test.

This article entered the Automotive Heat Treat archive in 2016, and was written by Andreas Schüler, Dr.-Ing. Jörg Kleff, Dr. Volker Heuer, Gunther Schmitt, and Dr. Thorsten Leist.

Read about here: "Distortion of Gears and Sliding Sleeves for Truck Gear Boxes – a Systematical Analysis of Different Heat Treatment Concepts"

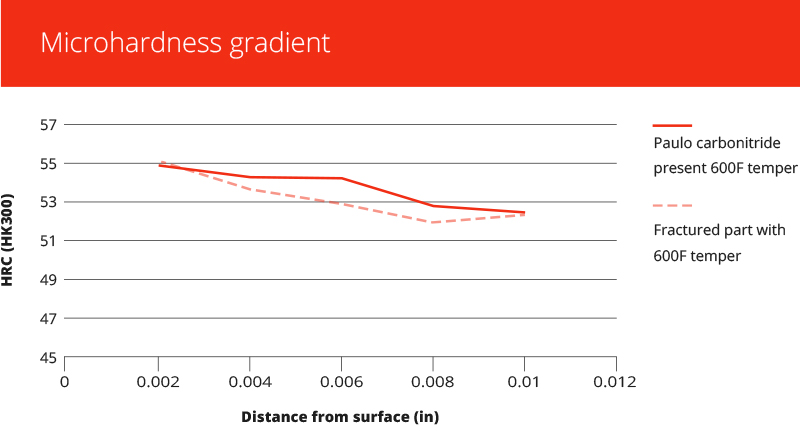

2. Cracking the Case

Problems in heat treating result in the loss of valuable time and money. Getting to the bottom of those problems also usually takes time and money to investigate what's happening and how to fix it. What is a heat treater to do?

Problems in heat treating result in the loss of valuable time and money. Getting to the bottom of those problems also usually takes time and money to investigate what's happening and how to fix it. What is a heat treater to do?

In this article, we follow a case study from the automotive industry to understand how to pinpoint a heat treating problem. This article specifically looks at what was causing cracking in variable valve timing (VVT) plates.

Read the 2018 article, "Part Failure Investigation & Resolution — A Case Study," by Rob Simons.

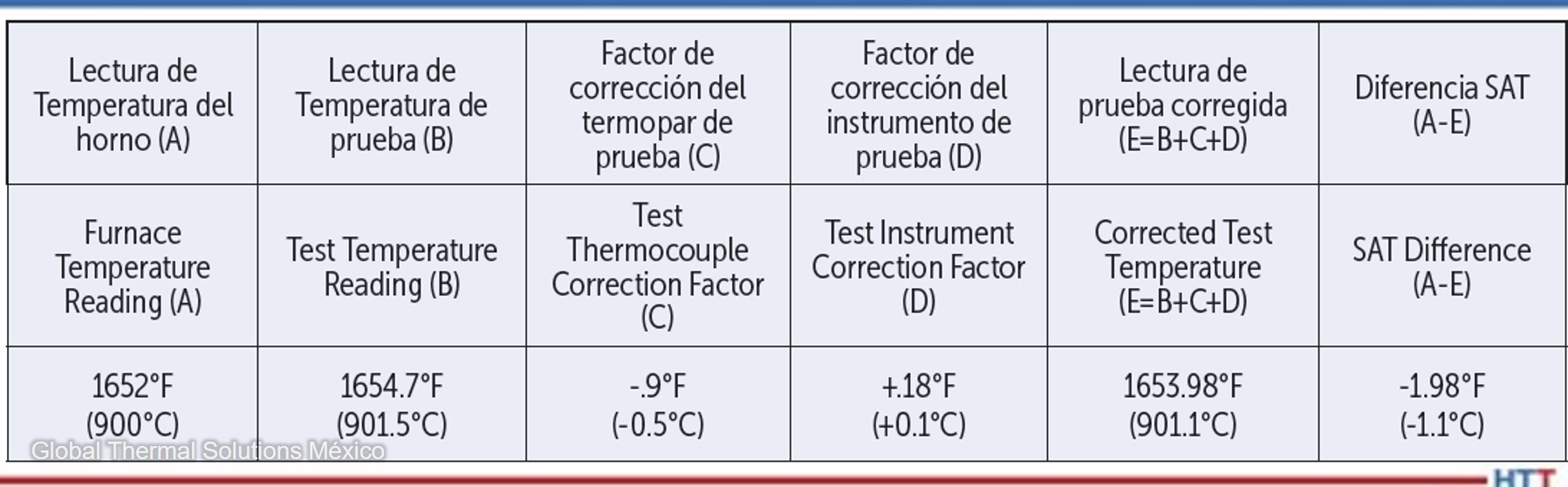

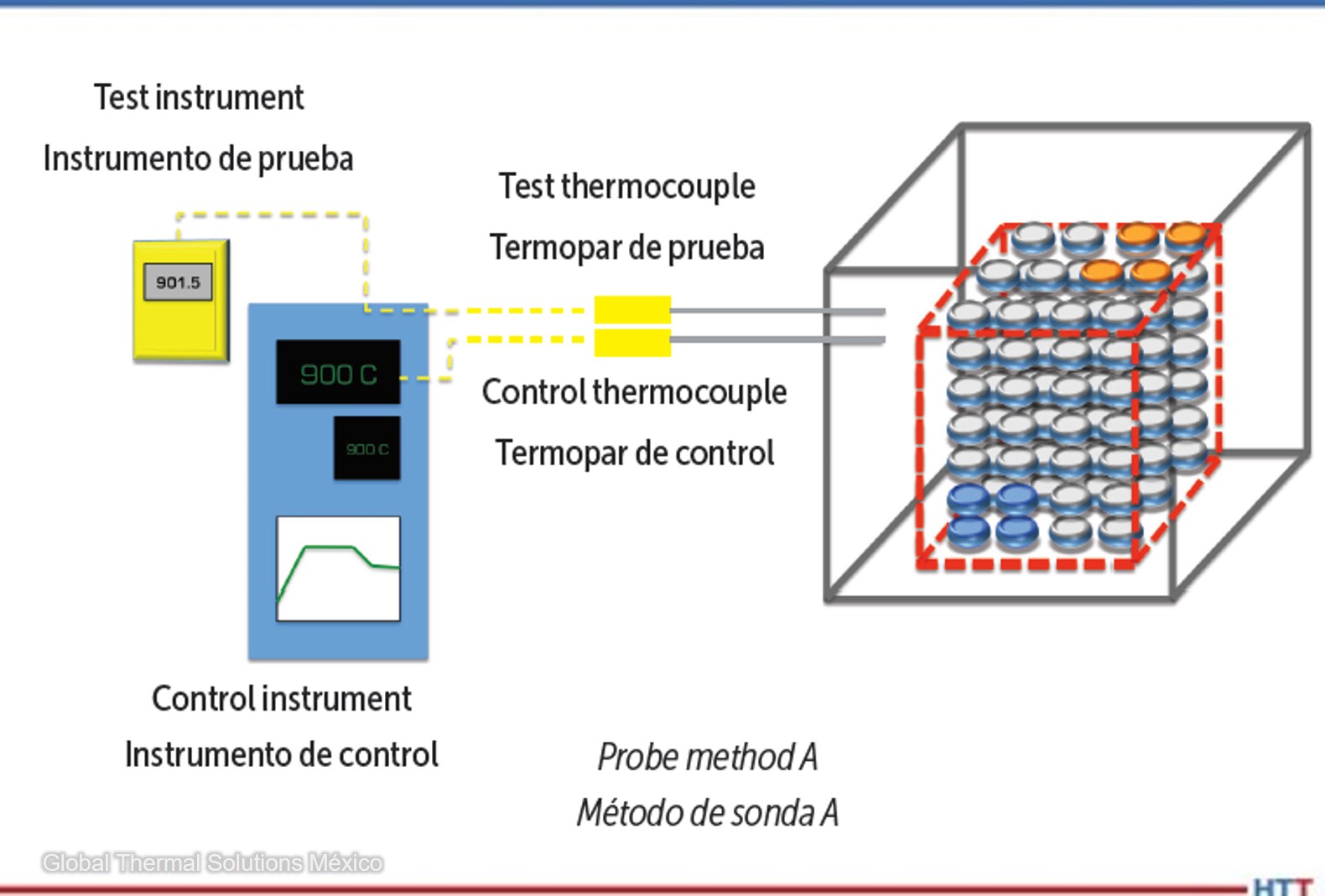

3. Carburizing: The Importance of Temperature Monitoring and Surveying

Low pressure carburizing (LPC) furnaces play an important role in the automotive heat treating industry. During LPC, it is essential that processing temperature stays consistent and critical that the processing time frame is monitored.

Low pressure carburizing (LPC) furnaces play an important role in the automotive heat treating industry. During LPC, it is essential that processing temperature stays consistent and critical that the processing time frame is monitored.

This article discusses the importance of collecting temperature data and what to do with the data when it's been collected.

Throughout 2019, Dr. Steve Offley wrote for this series, beginning with this part 1, "Temperature Monitoring and Surveying Solutions for Carburizing Auto Components: Introduction." When you're through, enjoy part 2, part 3, and part 4.

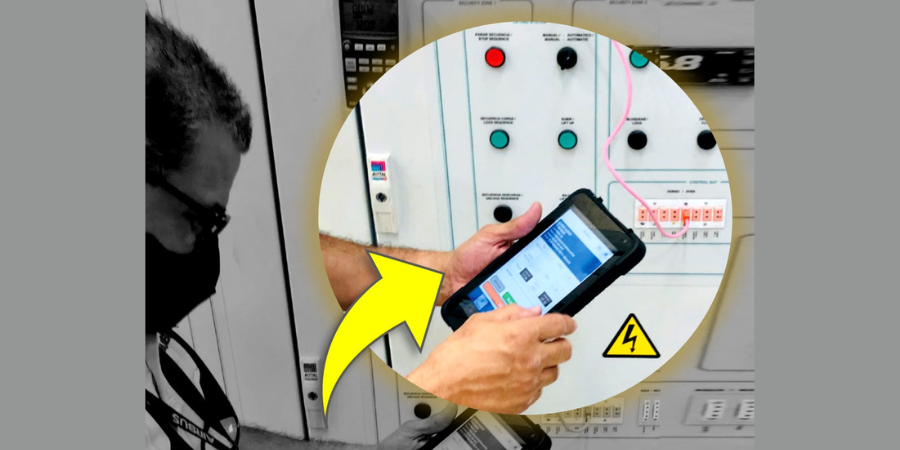

4. Vacuum Brazing --- Back to the (Automotive) Basics

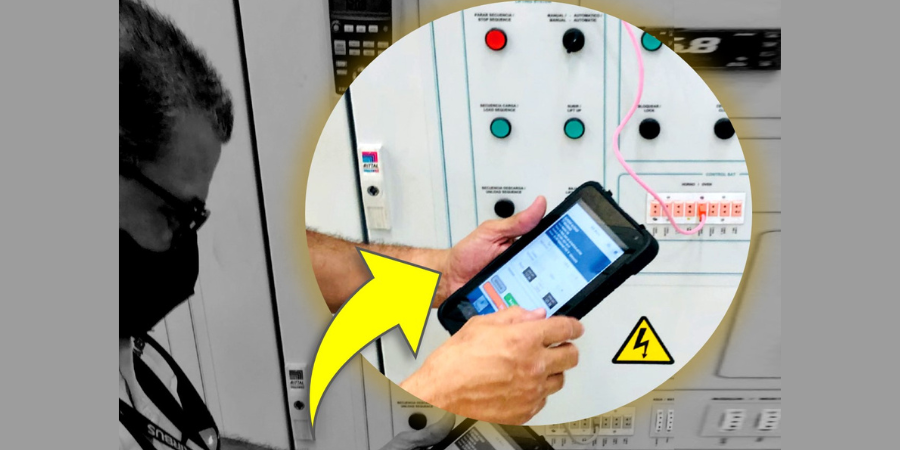

Time to brush up on a vacuum brazing furnace, but automotive industry style. Review the terms, parts, function, and more that are involved in a successful vacuum braze for automotive parts.

Time to brush up on a vacuum brazing furnace, but automotive industry style. Review the terms, parts, function, and more that are involved in a successful vacuum braze for automotive parts.

This study covers a semi-automatic TAV vacuum brazing furnaces, details the makeup of the furnace, and gives an idea of what happens with a load from start to finish.

Read this 2019 article by Alessandro Fiorese here: "Vacuum Brazing for Automotive Applications."

5. Saving Time --- Automation Versus Manual Hardness Tests

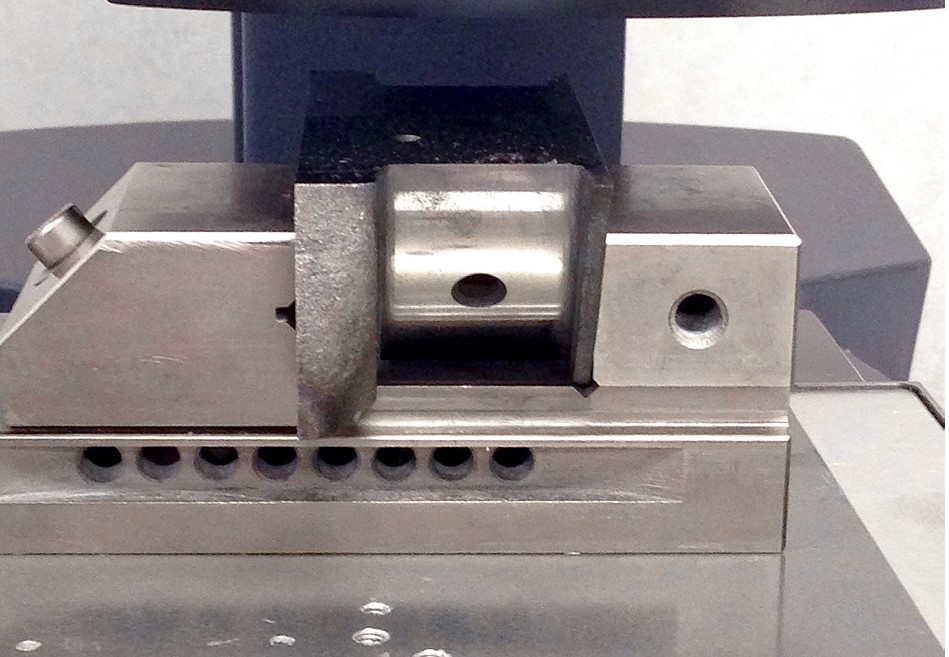

If you've ever heat treated automotive crank pins, you're probably familiar with at least one type of hardness test that case hardened crank pins are tested against. The big question is, which hardness testing method is better: automated or manual? This article compares these two methods to make and measure Vickers indentations.

If you've ever heat treated automotive crank pins, you're probably familiar with at least one type of hardness test that case hardened crank pins are tested against. The big question is, which hardness testing method is better: automated or manual? This article compares these two methods to make and measure Vickers indentations.

Evaluate for yourself the comparisons between an experienced operator manually entering data to Wilson VH3100 series Vickers Microhardness Tester and a DiaMet software entry. Some additional findings show that the crank pins could be examined by the Wilson tester with far less manipulation in the vice as well as reduction in data recording mistakes.

When you read this 2020 article by Buehler, "Manual Versus Automated Hardness Testing", learn exactly how much time, exactly, is saved with automation.

Find heat treating products and services when you search on Heat Treat Buyers Guide.com

Find heat treating products and services when you search on Heat Treat Buyers Guide.com

Dig into the Archives: 5 Technical Articles for Fresh Heat Treaters in Auto Read More »