Thermal Processing for Firearms: The Essential Guide

What do gas nitriding, hot isostatic pressing (HIPing), black oxide coating, and high pressure gas quenching have in common? They all are key processes in heat treating firearm components.

Written by Rob Simons, manager of metallurgical engineering at Paulo, this in-depth Original Content article covers Paulo’s perspective on the thermal processing of firearms components and best practices for handling and lot traceability.

Check out more of Heat Treat Today’s Technical Tuesday articles by searching “technical tuesday” in the search bar.

Manager of Metallurgical Engineering

Paulo

While many industries are continuing to reel from the ongoing coronavirus pandemic, the firearms industry in the United States is booming. Over the past decade, the sector’s strong growth has only accelerated in 2020, fueled by consumers’ response to the pandemic and ongoing civil unrest. According to the NSSF’s 2020 Firearm and Ammunition Industry Economic Impact report, the firearms industry is responsible for well over 300,000 American jobs—a figure that has doubled since 2008.

Consumer demand for firearms also drives the need for heat treatment services for this highly regulated industry. Proper thermal processing is critical for safety and also plays a key role in delivering the quality finish that manufacturers want and consumers expect. In this article, we’ll share our firearms heat treatment expertise, delving into the common processes, specifications, and considerations of servicing this thriving industry.

Key Heat Treatment Processes for Firearms Components

Gas Nitriding

Gas nitriding is used to case harden parts that must retain softer, more ductile cores. Because it is carried out at a lower temperature, gas nitriding helps prevent the part distortion that can sometimes occur as a result of conventional heat treatment. In addition to hardness characteristics, parts are often nitride coated for cosmetic purposes and to enhance corrosion resistance. Nitriding results in a beautiful, highly durable black coating that is often used in place of black oxide coatings or other blackening processes. Nitride coating is much harder than the alternatives, so the black finish will stand up to heavy use significantly longer.

Components and Materials Commonly Treated With Nitride Coating

Nitride coating is typically performed on outwardly visible components (and those you’d see while cleaning the gun) such as handgun slides and barrels, as well as muzzle devices such as flash hiders, muzzle breaks, and compensators.

These components are usually manufactured using the following materials, which can be nitrided to achieve the desired black finish and case hardness:

- 4140 steel. AISI 4140 is a chromium-, molybdenum-, and manganese-containing low alloy steel (usually referred to as chrome-moly steel). It has high fatigue strength, abrasion and impact resistance, toughness, and torsional strength.[1]

- Grade 416 stainless steel. Grade 416 steel is a free-machining, martensitic stainless steel with a machinability of 85%. [2]

- Grade 410 stainless steel. Grade 410 stainless steels are general-purpose martensitic stainless steels containing 11.5% chromium. Grade 410 steels have good corrosion resistance properties which can be further enhanced by hardening, tempering, and polishing.[3]

- Grade 420 stainless steel. Grade 420 stainless steel is higher incarbon than 410 with a minimum chromium content of 12%.

- 4340 steel. AISI 4340 alloy steel is a low alloy steel containing chromium, nickel, and molybdenum. When heat-treated, it exhibits high toughness and strength. This material is considered extreme duty and is typically used for higher-end firearms.[4]

- 17-4 stainless steel. 17-4 stainless steel is an age-hardening martensitic alloy combining high strength with the corrosion resistance of stainless steel. It is relatively cost-effective and more weldable than other martensitic alloys.[5]

Nitriding Specifications

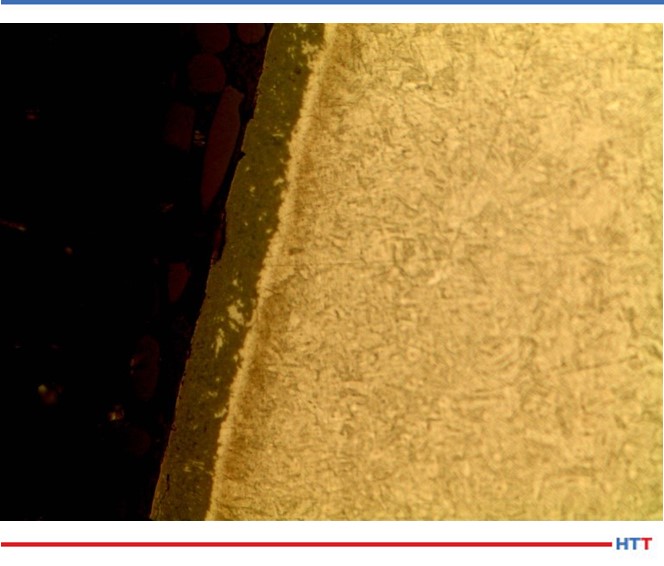

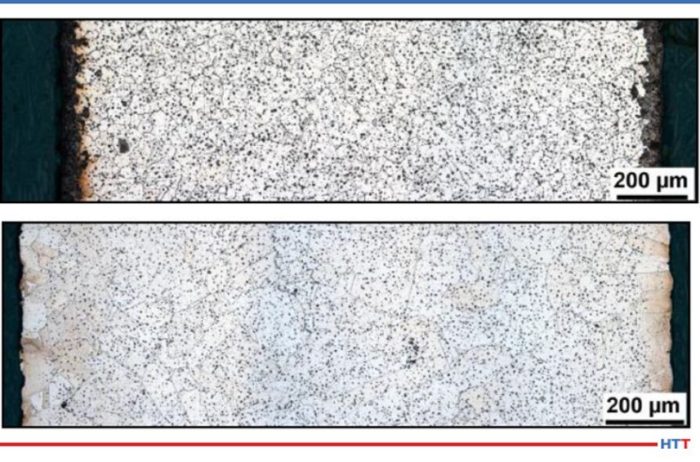

The most common measurement that firearms manufacturers specify in desirable nitriding results is intermetallic depth. Typical specifications fall between four and 25 microns of white layer depth. The amount of allowable porosity within the case depth is also commonly specified, and while there are varying ranges, less than 50% porosity is a typical target.

While porosity is often regarded as an undesirable characteristic, there are advantages to some porosity in the finished material. These microscopic voids can hold oils and enhance corrosion resistance. The resulting porosity in nitrided materials allows the coating to last dramatically longer than phosphate- or black-oxide-coated steels.

Some manufacturers utilize blanket aerospace specifications such as AMS 2757 or AMS 2959/12 because they encompass the desired porosity and case hardness depth for nitrided firearms components.

Vickers hardness testing is our preferred method for evaluating intermetallic depth in nitrided components. While 850 HV is typically the top achievable hardness for stainless steel, our team has consistently achieved 2000 HV with our nitriding processes. Higher-end hardness is beneficial for firearms components because it enhances wear resistance in components that slide against each other.

Hot Isostatic Pressing (HIP)

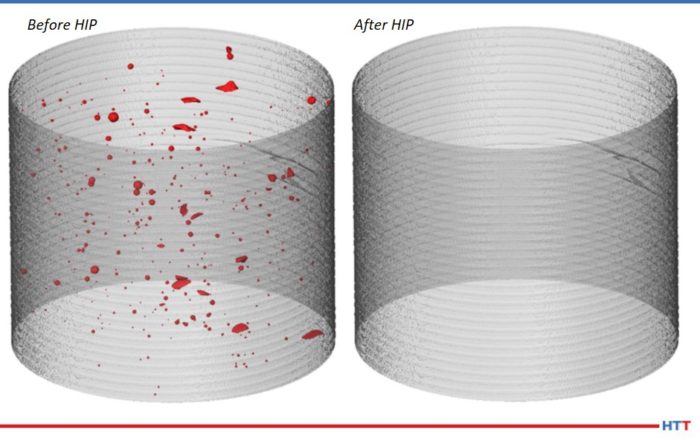

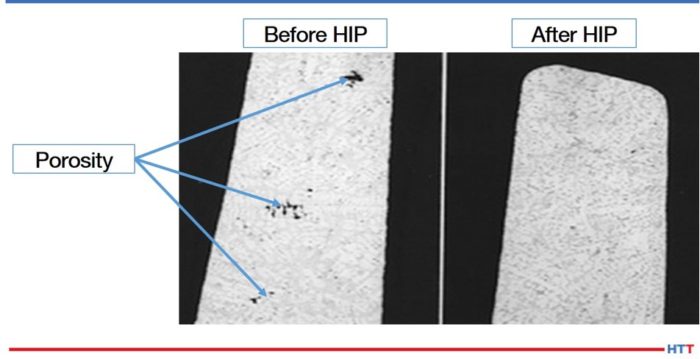

With hot isostatic pressing, parts are heated to very high temperatures in a sealed chamber capable of generating very high pressures in the presence of inert gas. During processing, heat and pressure combine to close the voids that formed during part manufacturing, eliminating weakness in the parts. Most firearms components respond well to standard coach cycles for HIP, which commonly run at 2050–2200°F and 15,000 psi.

Firearms Components and Materials Commonly Processed With HIP

HIP is especially well suited for removing porosity from metal injection molded (MIM), additively manufactured (AM), and investment cast parts.

MIM is a fast, cost effective way to produce fire control components such as hammers, triggers, and safety selectors, especially for AR-15’s. Traditionally, MIM components have had a reputation in the industry for being inferior to those manufactured with conventional machining because they have been known to fail early in the field.

Common MIM grades used in the manufacturing of firearms include 4140 steel, 17-4 stainless steel, and…

- FL-4605. FL-4605 is a low alloy steel with prealloyed manganese, molybdenum and nickel content for enhanced hardenability.[6]

- 420 stainless steel. 420 stainless steel is relatively high in carbon with a minimum chromium content of 12%, which gives it the highest hardenability of stainless steel grades.[7]

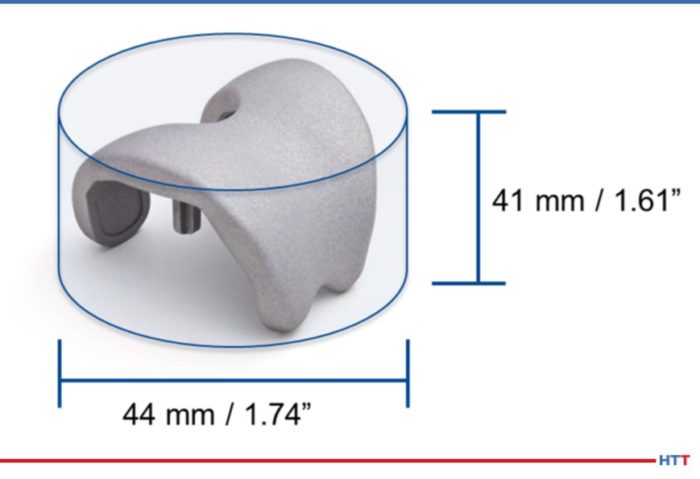

Additive manufacturing has not yet been widely adopted in the firearms industry, but we have seen it increasingly used in the manufacture of suppressors. These components—commonly known as silencers—trap the expanding gas as the weapon is fired to reduce noise, and are used for military sniper rifles. AM is an ideal method of manufacture for these components due to their complex geometry that is difficult or even impossible to achieve with traditional machining.

Investment casting is another process we see used in the production of handgun frames, specifically in the M1911 pistol.

MIM, AM, and investment castings all have one thing in common: these manufacturing methods leave voids behind in the internal structure of parts. HIP eliminates unwanted porosity in these parts, increasing their toughness, gross strength, and fatigue life which allows firearms components to withstand being repeatedly subjected to high impact.

HIP Specifications

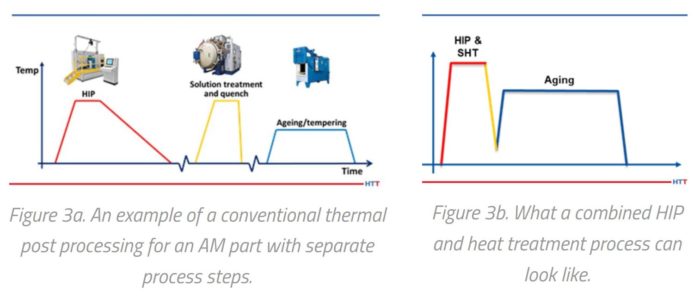

For additive manufactured firearms components, we encounter two primary specifications:

- ASTM F3301, a specification that outlines standards for thermal post-processing for metal parts made with powder bed fusion. ASTM F3301 identifies hot isostatic pressing as an acceptable means to stress relieve additive manufactured components.

- ASTM F3055, the standard specification for additive manufacturing nickel alloy with powder bed fusion. In this specification, HIP is required for Class B, C and D components and is considered optional for Class G.

In both specifications, components must be processed under inert atmosphere at no less than 100 MPa within the range of 2048 to 2165°F (1120 to 1185°C). Parts must be held at the selected temperature within ∓27°F (15°C) for 240 min ∓60 min, and cooled under inert atmosphere to below 797°F (425°C), or to parameters as agreed upon between the component supplier and purchaser.

Black Oxide Coating

Black oxide gives firearms a sharp black appearance, enhances corrosion resistance, and minimizes light reflection. Unlike paint, black oxide doesn’t add any additional thickness to gun components. The desired result in the black oxide process is creating magnetite (Fe3O4), an alloy of iron and oxygen, on the surface of the metal. The black oxide process enhances corrosion resistance by adding rust preventive oils to the metal part.

While it doesn’t last as long as gas nitride coating, black oxide is still a popular, cost-effective option to give visible gun parts the perfect black look. Finding a partner that can provide heat treatment and black oxide under one roof can reduce your transportation costs, speed up turnaround time, and simplify your overall process since one supplier owns the final results.

Firearms Components and Materials That Use Black Oxide Coating

Like nitriding, black oxide coating is used on outwardly visible components like slides, barrels, and muzzle devices including flash hiders, muzzle breaks, and compensators. It can be applied to any carbon steel component, but it will not adhere to stainless steel.

Specifications for Black Oxide Coating

Unlike nitriding and HIP, we rarely encounter standard specifications when it comes to black oxide results. However, as a best practice we work with customers to establish boundary samples for each part number treated with black oxide so we can compare our results to what both sides agreed upon as a desirable appearance.

High Pressure Gas Quenching

High pressure gas quenching can be performed in a vacuum furnace as an alternative to oil quenching for any firearms components that are near net shape or completely finished—or where distortion is a chief concern. In high pressure gas quenching, parts are austenitized under vacuum. Then, the chamber is backfilled with inert gas, which is heavily agitated by powerful motors.

High pressure gas quenching results in cleaner parts than oil quenching, but it has other benefits that can prove highly valuable for firearms components. This process can take a conventional 4140 alloy and make it achieve the same properties as a vacuum arc remelted (VAR) 4340, a much higher quality nickel-based material. This can allow firearms manufacturers to see similar hardness and strength results in everyday components as those they would expect from an extreme duty material like 4340.

Handling and Traceability for Firearms Components

No heat treater should make a habit of losing any type of parts, but the implications for serialized firearms components are more severe than any other mass-produced components. Serialized components are what the U.S. government considers the firearm—it refers to the part that features the serial number, usually the lower frame assembly and sometimes the barrel or slide.

Firearms components to be treated with gas nitriding that have AMS 2757 or AMS 2759/12 identified as the standard are also subject to the recordkeeping guidelines outlined in the specification. AMS 2757 requires that documentation includes the equipment and approved personnel’s identification, date of processing, number of parts, alloy, lot identification, and actual thermal processing times and temperatures at a minimum.

Proper handling of firearms components by heat treaters is essential to keep the supply chain running smoothly. Improperly heat treated parts will either wind up in the scrap bin or require reprocessing, and lost parts can result in an ATF audit or investigation. At our company, we’ve engineered our process to prevent issues from occurring in the first place. Here are a few examples of how we do it:

- Electronic tracking. Each lot of parts is assigned a barcode that links to electronic records of all relevant information about the job—process parameters, specifications, shop orders, etc. The process parameters on the parts’ barcode are integrated with equipment, so when parts are scanned for processing, the furnace will be automatically set to the proper parameters according to the parts’ recipe. This helps us prevent parts from being improperly heated or subject to the wrong process altogether.

- Secure storage. In Paulo plants that process firearms, we use locked cages and secure vaults to protect serialized components. All access to these areas is monitored and recorded to maintain accountability and, if applicable, adhere to AMS specifications.

- Specialized handling. To give our firearms customers more peace of mind and to safeguard against errors in our process, we’ve also engineered secure fixturing for many components that allows them to remain locked throughout the entire heat treatment and finishing process.

In addition to a Federal Firearms License (FFL), heat treaters should also have a documented quality management system in place. Choosing an ISO 9001-certified supplier can help give manufacturers confidence in a heat treating partner’s ability to maintain quality operations. Maintaining other certifications such as IATF 16946 and CQI-9 is also a good sign that your partner is well equipped to handle firearms work.

Conclusion

The firearms industry relies on its thermal processing partners to sustain its growth. Proper heat treatment and metal finishing results in better performing, longer lasting firearms for our military and law enforcement, which helps keep our country safe. In uncertain times, the firearms industry represents a bright spot in the U.S. economy that we are proud to support.

About the Author: Rob Simons is manager of metallurgical engineering at Paulo where he leads the commercial heat treating industry’s largest in-house metallurgy team. Rob continuously spearheads research and innovation at Paulo that lead to advanced capabilities and better results for the company’s customers. Rob holds a bachelor’s degree in Metallurgical Engineering from the Missouri University of Science & Technology.

About Paulo: Founded in 1943, Paulo is one of the largest providers of thermal processing and metal finishing solutions in North America. Headquartered in St. Louis, Paulo operates six divisions servicing the United States and northern Mexico.

[1] https://www.azom.com/article.aspx?ArticleID=6769

[2] https://www.azom.com/article.aspx?ArticleID=971

[3] https://www.azom.com/article.aspx?ArticleID=970

[4] https://www.azom.com/article.aspx?ArticleID=6772

[5] https://www.azom.com/article.aspx?ArticleID=4220

[6] https://www.ssisintered.com/materials/low-alloy-molybdenum-nickel-steels

[7] https://www.azom.com/article.aspx?ArticleID=972

All other images are provided by Paulo.

Article updated on Thursday 4/29/2021 at 3:22pm.

Thermal Processing for Firearms: The Essential Guide Read More »