Lukasiewicz– IMN Enhances R&D with Vacuum Furnace

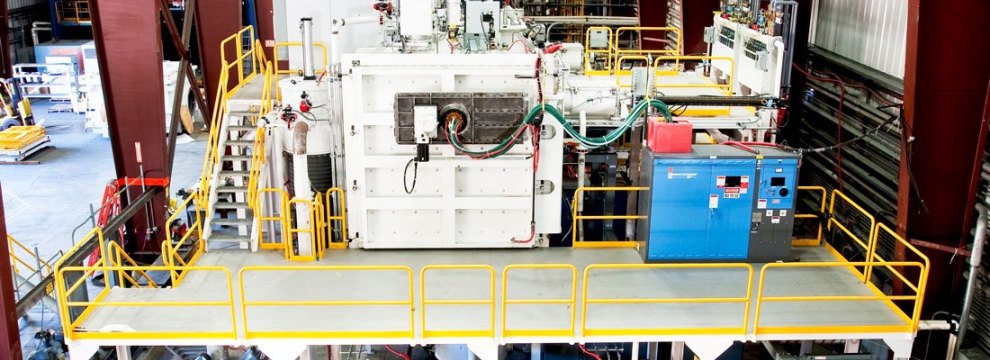

Łukasiewicz – the Institute of Non-Ferrous Metals (Łukasiewicz – IMN) recently expanded its heat treating operations with a VIM furnace for melting metals and metal alloys on a laboratory scale. The new equipment will be used to develop new types of alloys, make individual castings, and conduct research on melting processes.

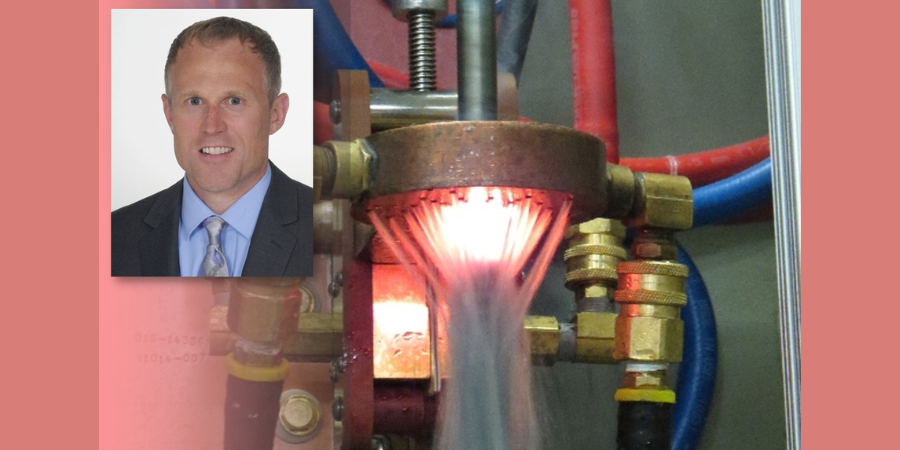

The vacuum induction melting furnace, ordered from SECO/WARWICK, has a maximum operating temperature of 2000˚C (3,632°F) and a single-chamber VIM furnace. It was designed to produce metal and alloy castings weighing up to 20 kg in vacuum, or under pressure using an inert gas (argon).

President & CEO

SECO/WARWICK Group

Source: SECO/WARWICK

This is the second processing solution the furnace supplier has designed for the institute. Łukasiewicz – IMN, a member of the Łukasiewicz Research Network, received a targeted subsidy for the implementation of an investment related to scientific activities for the purchase of research equipment granted by the Ministry of Education and Science (currently the Ministry of Science and Higher Education).

“Scientific institutions are one of the group of recipients for our solutions,” said Sławomir Woźniak, CEO of the SECO/WARWICK Group. “For example, we have supplied solutions to the Karlsruhe Institute of Technology (KIT), which ordered a non-standard, 12-meter vertical rotary retort furnace for the heat treatment of a gyrotron part, as a contribution to the ITER experimental thermonuclear reactor. We have also supplied laboratory furnaces for the Institute of Precision Mechanics. We invest heavily in research and development ourselves. We have our own R&D centers, which allow us to continuously improve the technology we offer.”

The press release is available in its original form here.

Find heat treating products and services when you search on Heat Treat Buyers Guide.Com

Lukasiewicz– IMN Enhances R&D with Vacuum Furnace Read More »