Digitalization Propels Heat Treating to Industry of the Future

If you work in a standards-driven industry, you may already feel the imperative of digitalization. In today’s Technical Tuesday, Mike Loepke, head of Nitrex Software & Digitalization, posits how, even if you aren’t necessitated to track compliance digitally, you are probably looking to synthesize and leverage the strengths of multiple advanced operations — furnace and process record-keeping, knowledge of furnace past operations, juggling different new equipment capabilities — across just one platform. In other words, you are looking to bring digitalization system management to your operations.

This informative piece was first released in Heat Treat Today’s December 2024 Medical & Energy Heat Treat print edition.

The Future of Heat Treatment Relies on Digitalization

The ultimate goal for heat treaters, whether commercial or captive, is to uphold the quality of their product and meet client expectations while remaining profitable. Digitalization supports these efforts as it synthesizes and presents detailed, transparent, and accessible data that allows heat treaters to better manage their equipment, processes, and product quality. In addition, the collection of detailed information can serve as a database of knowledge to be used by the next generation of heat treaters, supporting future viability and advancement in the field.

There are necessary steps to take to establish a digital solution and essential components to look for when choosing a software platform that assists heat treaters in optimizing equipment and processes, effectively creating the digitalization of the heat treat operations. Let’s explore these now.

How Digitalization Optimizes Heat Treatment Processes

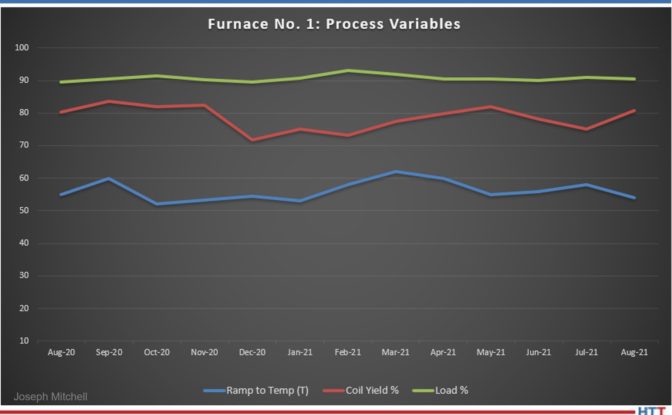

Digitalization in the heat treatment industry relies on the integration of industrial internet of things (IIoT) technologies with traditional and modern heat treatment processes. Using enabling devices such as sensors, modern connectivity methods, analytics, machine learning, and IIoT software platforms, it is possible for heat treaters to collect and process data that, after analysis, drives informed decisions to optimize equipment, processes, and product quality. To put a finer point on it, digitalization occurs when a manufacturing system is digitally integrated to capture and preserve human experience and knowledge, forming a holistic virtual representation of heat treat operations.

Source: Nitrex

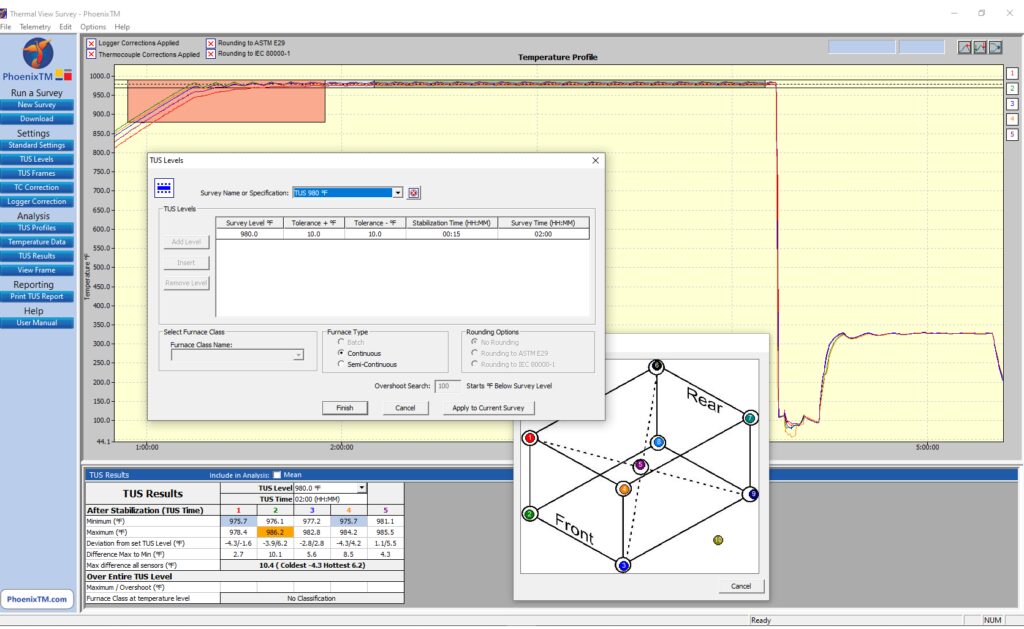

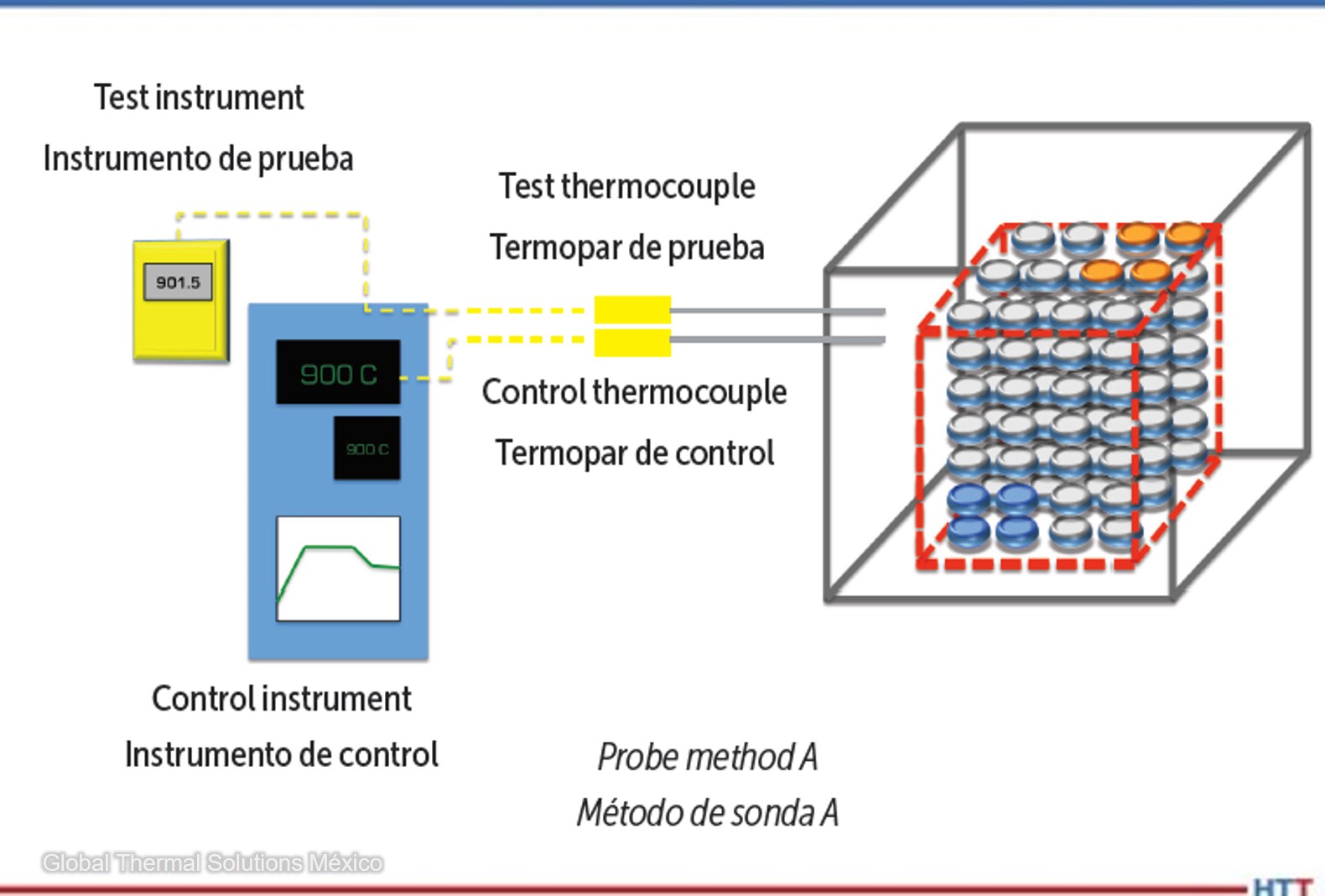

While digitalization varies from industry to industry and plant to plant, there are some common ways in which heat treaters can employ digital technologies to build such a system. Firstly, digitally integrated solutions can optimize process management and control. For example, when a sensor detects a temperature anomaly during a heat treatment process, the integrated software platform picks up that reading, analyzes it in real time, recognizes it as an error based on historical data or programmed parameters, and alerts the operator.

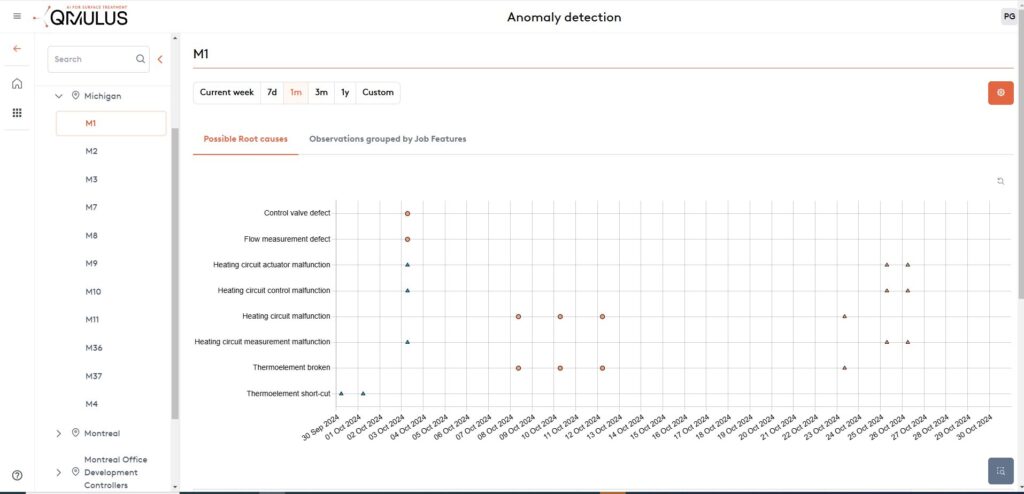

This integration also facilitates predictive, condition-based maintenance. For example, if collected data and analysis suggests that a furnace is behaving abnormally, the system can automatically generate a work order along with a list of potential failure causes, so that a technician can troubleshoot, identify, and correct small issues — such as a failing thermocouple — before they impact quality or result in equipment failure. By addressing these proactively, heat treaters can avoid extended periods of costly unplanned downtime and ensure continuous operation.

Secondly, artificial intelligence through machine learning plays a crucial role in optimizing quality control in a digitalized system. By analyzing data collected during heat treating processes, it learns to detect patterns and identify anomalies. As in the examples above, this capability enables the system to identify deviations from the desired outcomes, allowing heat treaters to quickly rectify any issues before they impact quality.

Source: Nitrex

Thirdly, algorithms can be programmed into a comprehensive management system to identify the most energy-efficient operating conditions for the heat treating process, helping heat treaters reduce their carbon footprint, minimize energy costs, and comply with sustainability goals.

In addition to these types of operational advantages, digitalization technologies can also be used to create a database of knowledge before experienced operators and experts leave the workforce. Traditionally, a handful of experts in the plant oversee the furnaces and equipment and understand how to best control and maintain them based on experience. However, passing down this knowledge to the next generation of heat treaters can take years, which may not be possible due to a company’s workflow demands and cost pressures. Digitalization addresses this challenge by creating a streamlined and accessible database of knowledge, offering less experienced operators and technicians immediate access to detailed information about what may be happening in the equipment or process for an issue at hand. This ensures that essential insights are not lost and enables quicker problem-solving and decision-making on the shop floor.

Making the Digitalization Transformation

While digitalization presents obvious advantages, the heat treatment industry, often conservative in its approach to technology, has some initial work and investment required before realizing the full benefits.

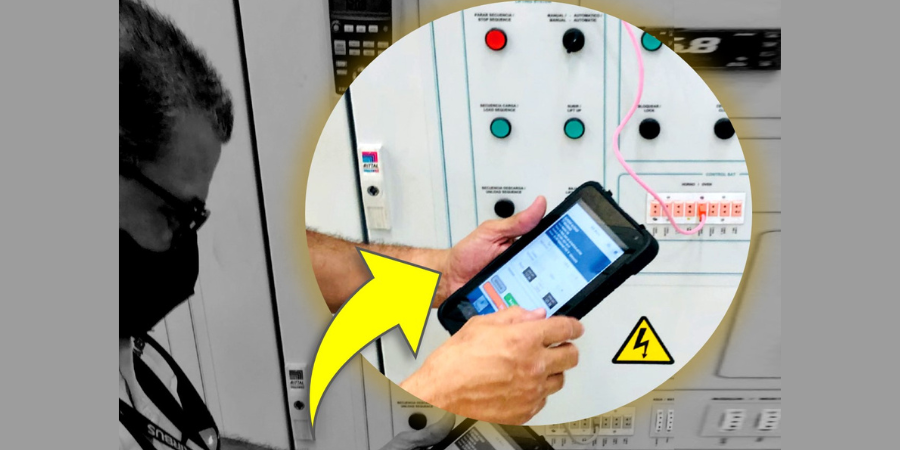

Going “paperless” in order to unlock the full potential of the available data is an important first step. All reports, histories, drawings, and other paperwork associated with equipment, processes, maintenance activities, product quality, and other relevant information should be digitized to provide a comprehensive view of both historical and current data.

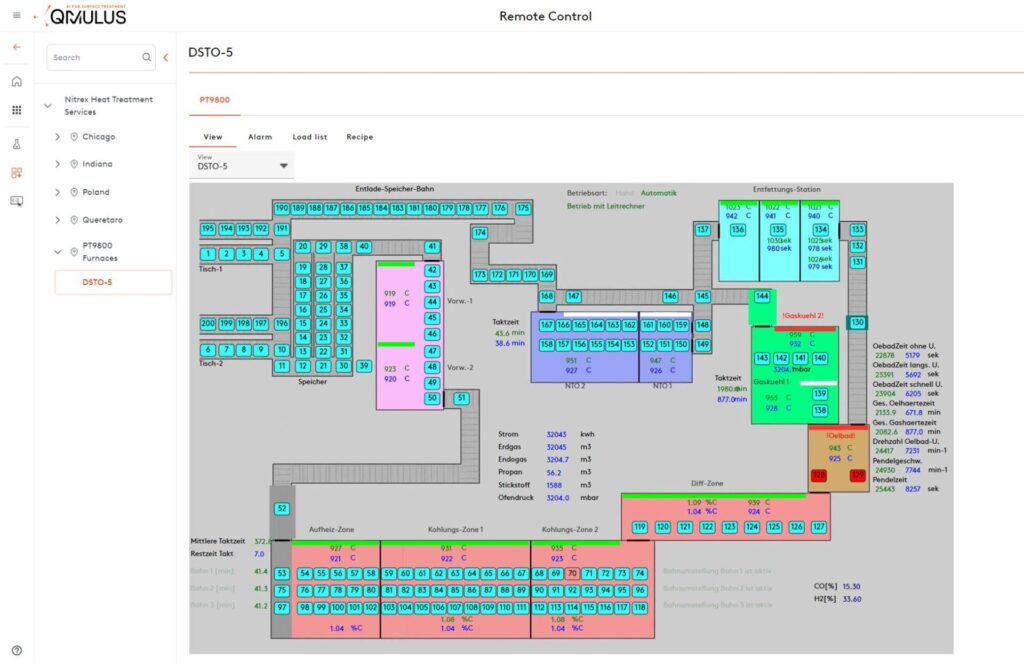

Connectivity and integration between machine and higher-level systems are essential for effective data acquisition, monitoring, and remote control. SCADA systems, Manufacturing Execution Systems (MES), and other higher-level systems are rich sources of machine and process data. Gathering and analyzing this data can provide actionable insights that operators can use to make smarter decisions about the control and maintenance of equipment and processes.

Source: Nitrex

Finally, just having data is not enough. The data must be accessible, transparent, and relevant to be valuable. Achieving a complete picture of all the collected data, known as data consolidation, is necessary.

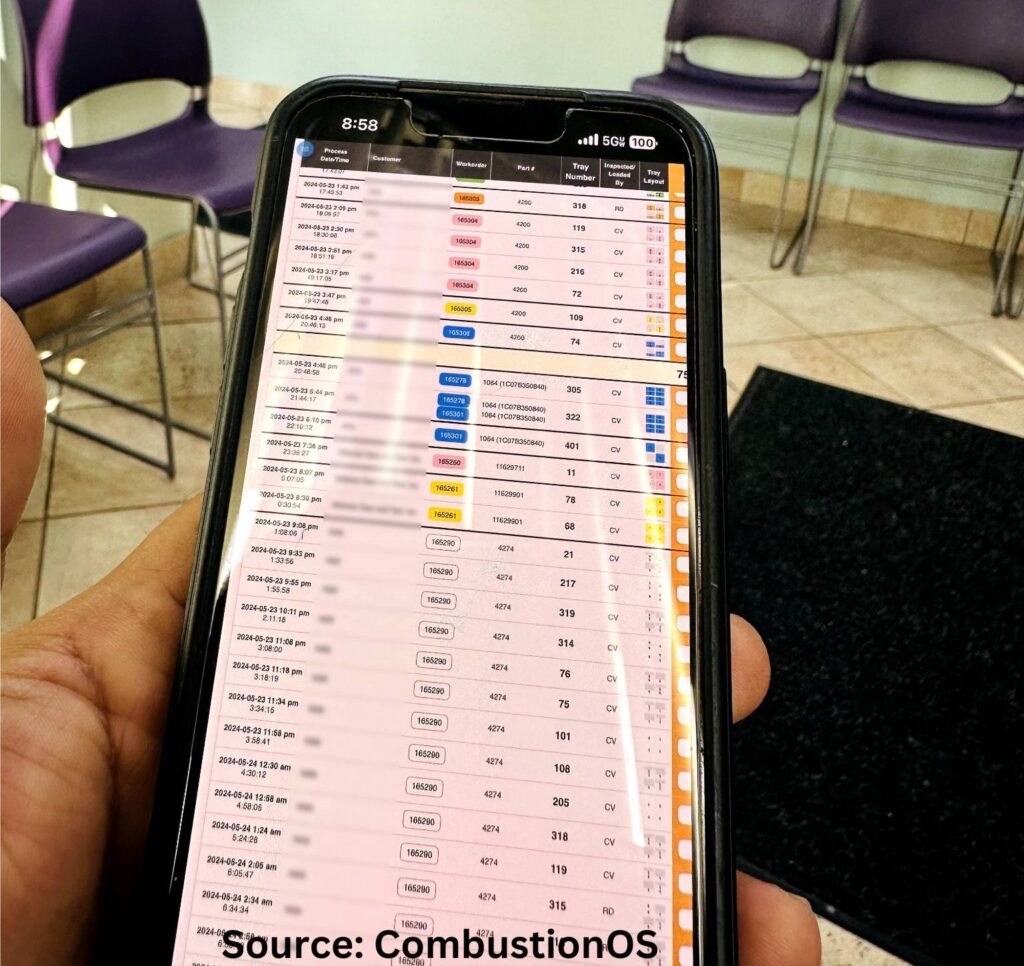

To build an IIoT platform with a well-architectured data engine, heat treaters should begin by identifying and understanding the different sources of data provided by sensors and high-level systems. This involves integrating the data through interfaces adapted to the data type and source, as well as documenting the integrated data sources, data fields, and data streams. Next, a “data lake” should be created to store the collected raw data. From this foundation, a data warehouse can be established to store enriched or analyzed data, derived values, data models, and forecasts in an organized way. For heat treaters, this type of contextualized data might be grouped by parts, loads, or orders.

Once the data engine is in place, the information stored in the data warehouse must be presented in a way that makes sense to operators and technicians for them to make informed decisions for heat treatment processes. To facilitate this, a universal data interface should be considered.

Building from this well-architectured data engine, the IIoT platform can then be expanded with statistical analytics, remote monitoring, KPI tracking, machine learning, artificial intelligence, and other applications to optimize processes and increase profitability.

What Heat Treaters Need in a Digitalization Solution

Harnessing modern technologies tomake digitalization a reality presents heat treaters with the opportunity to implement a solution based on a complete and well documented data system. It also means that the solution creates a holistic solution to data analysis, interpretation, reporting, and action that supports the real-world actions of heat treaters on the plant floor and in the office.

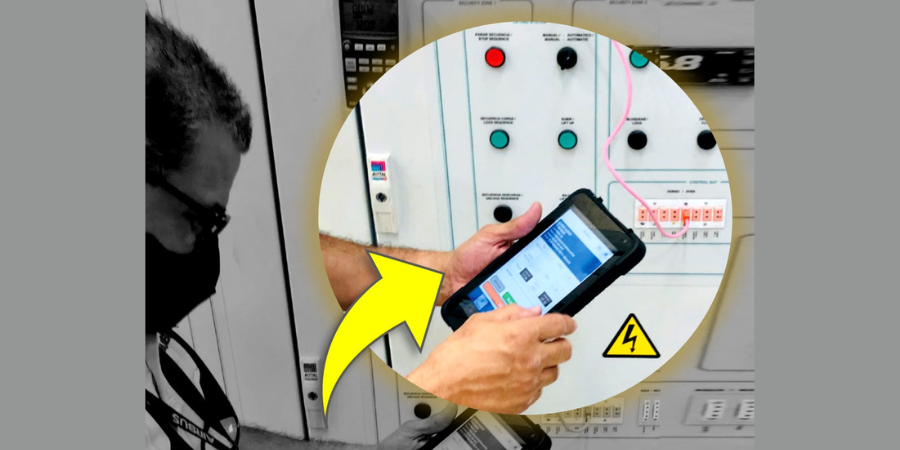

For this reason, a digitalization solution that has cloud and on-premises allows real-time access to analysis and alert messages for operators on the floor as well as managers who are away from the plant, ensuring quick problem-solving and maximum uptime in the event of process or machine issues.

Additionally, heat treaters should look for a solution that offers the freedom to integrate all the various platforms and equipment from which data are gathered from. These may include relevant machinery and production data from the shop floor as well as third-party and custom controllers. This flexibility to synthesize information from multiple sources will ensure the digitalization efforts lead to a comprehensive solution with actionable process overviews, recipe control, batch tracking, and other customization options.

To further this intent of a holistic solution, heat treaters should consider various data capabilities with different portal views, such as a manufacturer portal, a plant portal, and a client portal. However, considering the historic value of a comprehensive software solution, it may be worthwhile to consider how each user could transfer direct feedback and add new rules into the system, creating a repository of knowledge that bridges the knowledge of outgoing generations to future heat treaters.

Finally, any platform that directs the digitalization of a plant must prioritize robust security measures. Several features to look for are:

- enhanced encryption standards to keep data confidential and tamper-proof during transmission and storage;

- secure protocols based on industry best practices to safeguard data integrity;

- a granular access control system (ACS) to allow IT administrators to define and manage user permissions of authorized personnel, thereby minimizing the risk of data breaches and unauthorized data manipulation; and

- intrusion detection and prevention systems to continuously monitor network and system activities, enabling instant identification and mitigation of suspicious behavior. This serves as an additional layer of defense against potential cyber threats.

Beyond the software setup, be sure to use best practices by conducting regular security audits to assess the platform’s vulnerabilities and ensure compliance with evolving cybersecurity standards. While digitalization of heat treat operations may seem like a task for the next generation to complete, secure software options that integrate the hard work of digitizing plant activities can make this endeavor just a step away.

About the Author:

Head of Nitrex Software & Digitalization

Nitrex

Drawing from a background in Mathematics and Physics, coupled with extensive R&D experience and metallurgical modeling, Mike Loepke specializes in AI and process prediction. He has led Nitrex’s initiative in developing QMULUS, a pioneering IIoT cloud-based platform. Mike’s relentless pursuit of knowledge keeps him at the forefront of evolving technology.

.

For more information: Contact Mike at mike.loepke@nitrex.com.

Find heat treating products and services when you search on Heat Treat Buyers Guide.Com

Digitalization Propels Heat Treating to Industry of the Future Read More »