Combustion Corner: Natural Gas 101

Natural gas. It’s a necessity for producing energy and a staple in the heat treating industry. In this reader-friendly and thorough guide of all things natural gas, learn about its supply and demand, availability, pricing, consumption and much more.

Natural gas. It’s a necessity for producing energy and a staple in the heat treating industry. In this reader-friendly and thorough guide of all things natural gas, learn about its supply and demand, availability, pricing, consumption and much more.

This column will appear in Heat Treat Today’s 2021 Atmosphere-Air February print edition.

Heat Treat Today is pleased to announce that John Clarke, technical director at Helios Electric Corporation, will be writing about combustion related topics throughout 2021. John has been a long-time friend of Heat Treat Today and his expertise in system efficiency analysis, burner design as well as burner management systems will be incredibly helpful as he navigates us through all things energy as it relates to heat treating equipment.

Technical Director

Helios Electrical Corporation

This article is the first in a series describing trends in energy use and technology used in heat treating equipment. So, it is important to first discuss the supply and demand for natural gas–the energy source on which we depend for not only combustion for heating, but also to generate a substantial share of our electricity.

Heat treaters, be they captive or commercial, are dependent on natural gas to power their operations. Its price and availability are areas deserving special attention from anyone responsible for the purchase, maintenance, and operation of heat-treating equipment.

The good news is that the sky is not falling. In fact, it is a pleasant and sunny day, figuratively speaking. The bad news is that we are increasingly dependent on this one energy source. The economic impact from rapid spikes in cost will be even more severe than they were in the 2005-2009 period, when the United State saw prices for natural gas double in just a few days.

But wait: “Danger, Mr. Robinson” (Imagine a robot with vacuum cleaner hoses for arms shouting a warning to all of us). Is it really that simple? Can I invest my resources with confidence that the price for my energy will remain constant? Should I hedge my bets by spending more on increased efficiency? What is the impact on my return on investment? Can I count on the availability of this energy source? Critical questions all, and questions we will address in this and subsequent articles.

What is Natural Gas?

Natural gas is a mix of a number of hydrocarbons with 80 to more than 90% methane (CH4) and lesser quantities of ethane(C2H6), propane(C3H8), heavier hydrocarbons, carbon dioxide (CO2) and/or nitrogen(N2). The composition varies depending on the source, but it averages a higher heating value (HHV) of around 1,000 British thermal units (BTU) per standard cubic foot (SCF). This fuel can be used directly to heat our equipment and is being used, in increasing quantities, to generate our electricity.

Domestic Production

Advances in horizontal drilling and hydraulic fracturing (fracking) have greatly expanded our domestic production of both oil and natural gas, releasing otherwise “tight” gas and oil previously trapped in shale formations. This has made recovering these sources of natural gas economically feasible. The supply of shale natural gas grew sevenfold in the last 15 years and now represents roughly two-thirds of our total domestic production of gas. (2005 shale gas production was less than 10 billion cubic feet per day to over 70 billion by 2020.)3 Furthermore, the Energy Information Agency (EIA) — an agency within the Department of Energy charged with tracking US energy production, consumption, and project future demand and supply– projects an increase in US domestic production through at least the year 2050.

Domestic Consumption

Natural Gas Use by Sectors in the US, 2019 and Change Since 20094

Total Consumption 2019 31 Trillion Cubic Feet

Total Consumption 2009 23 Trillion Cubic Feet

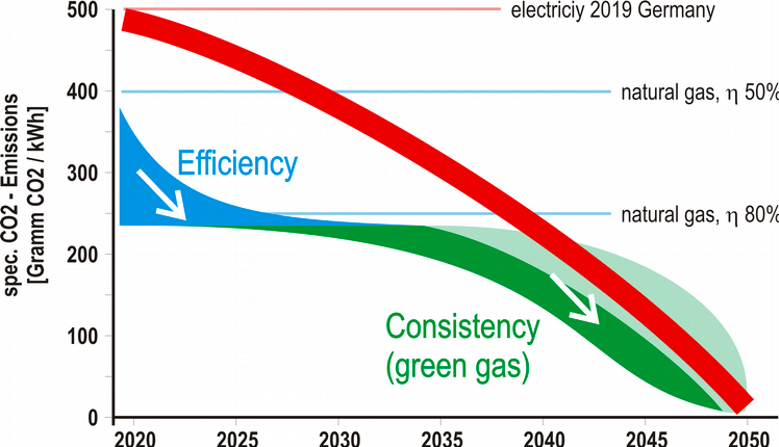

Efforts to reduce CO2 emissions from electrical power generation and reduce the cost of new generating capacity have led to a rapid expansion of electricity generated using our abundant supply of domestic natural gas. Switching from coal to natural gas reduces CO2 emissions by nearly 59% per unit of electricity generated. (See table “U.S. electric utility and independent power… by fuel 2019”)5 Noteworthy Trend – Electrical Power Generation

In the last 10 years, coal consumption for electricity generation has fallen 48% while natural gas’s contribution has gone up 60%.6 This investment in new natural gas fired electrical generating facilities has created a very stable demand. It is likely that this trend will continue as coal plants are shuttered in favor of the cheaper and cleaner natural gas alternative. In the long run, renewables, specifically solar and wind, may displace some of this natural gas consumption, but in the near term, coal is the most likely fuel to be displaced. The demand for electricity produced by natural gas will be buoyed further by the rapid expansion in the use of electric vehicles.

Exports – Liquified Natural Gas (LNG)

The US was a net exporter of LNG in 2017 and 2019. Our export capacity has expanded nine-fold from 2016 to 2019, growing from 0.36 trillion cubic feet per year in 2016 to 3.24 trillion cubic feet per year in 2019. As our capacity to export natural gas expands, it is likely that an increase in international demand will place upward pressure on domestic prices.

Externalities – The Unpredictable

There are factors that are, by their very nature, impossible to quantify. They remain a risk, nonetheless. As political power shifts in Washington, it is likely that politicians will pursue legislation to reduce CO2 emissions. The Biden administration, for example, could seek to reduce coal consumption by switching to natural gas as a means to generate electricity. Regulations or moratoriums on fracking might reduce our ability to expand production in the face of rising demand. The U.S. may seek to export more natural gas to reduce allies’ dependency on natural gas produced by our geopolitical rivals. On balance, the net effect of these political factors cannot be predicted and modeled with any certainty.

Other non-political factors make our future less clear. Weather remains a constant unknown and as natural gas’s share of electrical generation expands, both hot and cold weather can lead to an increase in demand. Furthermore, excessive speculation could also introduce instability to prices if not supply. Remember Enron and the effect on electrical power prices and supply in California in 2000 and 2001.

Conclusion

With any luck, we will see no national supply or demand shocks that will imperil the availability of natural gas for U..S industry. I am concerned that prices will rise and fluctuate as a result of one or more of the factors highlighted in this article. These risks should be considered when making equipment acquisition, maintenance, and operating decisions. In the upcoming articles, we will focus on technologies and practices that can help to mitigate these risks as well as save both energy and money.

Endnotes:

[1] “Natural gas explained: Factors affecting natural gas prices,” Independent Statistics & Analysis U.S. Energy Information Association. https://www.eia.gov/energyexplained/natural-gas/factors-affecting-natural-gas-prices.php.

[2] Ibid.

[3] “Natural gas explained: Where our natural gas comes from,” Independent Statistics & Analysis U.S. Energy Information Association. https://www.eia.gov/energyexplained/natural-gas/where-our-natural-gas-comes-from.php.

[4] “Natural gas explained: Use of natural gas,” Independent Statistics & Analysis U.S. Energy Information Association. https://www.eia.gov/energyexplained/natural-gas/use-of-natural-gas.php.

[5] “FREQUENTLY ASKED QUESTIONS (FAQS): How much carbon dioxide is produced per kilowatthour of U.S. electricity generation?” Independent Statistics & Analysis U.S. Energy Information Association. https://www.eia.gov/tools/faqs/faq.php?id=74&t=11.

[6] “Electric Power Monthly: Table 1.1. Net Generation by Energy Source: Total (All Sectors), 2010-October 2020,” Independent Statistics & Analysis U.S. Energy Information Association. https://www.eia.gov/electricity/monthly/epm_table_grapher.php?t=epmt_1_01.

About the Author:

John Clarke, with over 30 years in the heat processing area, is currently the technical director of Helios Corporation. John’s work includes system efficiency analysis, burner design as well as burner management systems. John was a former president of the Industrial Heating Equipment Association and vice president at Maxon Corporation.

Combustion Corner: Natural Gas 101 Read More »