DUAL PERSPECTIVES: Europe vs. North America

Changes are inevitable, but the world today is changing so rapidly that it’s constantly keeping us on our toes. Do two men from different parts of the world and lots of experience within the heat treating community have vastly different perspectives on the happenings in the heat treat industry?

We want to find out, so we asked a question that focuses on the world of heat treating to Thomas Schneidewind, the editor-in-chief of heat processing magazine, and Doug Glenn, the publisher and founder of Heat Treat Today. The question: Will the war in Ukraine impact the heat treat industry?

Thomas’s expertise lies in the European market while Doug’s resides in the North American market. We will feature their responses in each print magazine. Will their views align? Time will tell. Enjoy this first installment of an ongoing column. This column was first published in Heat Treat Today’s May 2022 Induction Heating print edition.

Will the War in Ukraine Impact the Heat Treat Industry?

Will, or how will, the war between Russia and Ukraine directly or indirectly impact the industry? What immediately comes to mind?

Thomas Schneidewind, Editor-in-Chief, heat processing magazine

Editor-in-Chief

heat processing Magazine

First of all, the war in Ukraine is a humanitarian catastrophe. And the first war in Europe since 1945 marks a turning point in history. It has a strong impact on the global economy and hits the thermprocess industry in particular. The exploding energy prices lead to shutdowns of sites in the steel industry. That means that some investments will be frozen.

Europe’s Turning Point

Due to the economic downturn more and more companies are facing another difficult year. Machine and plant builders are affected by the imposed sanctions. Most of the companies are engaged in Russia and in Ukraine as well. One example: Against the background of the war in Ukraine and the human suffering associated with it, SMS group has ceased its main business activities in Russia and Belarus, with the exception of safety-critical maintenance work. New orders will not be accepted. All companies who have strong relationships with clients in Russia and Ukraine are taking care of refugees. SMS will be taking in one hundred families from Ukraine at its German locations in Hilchenbach and Mönchengladbach.

In Europe we see a completely new set up of the political agenda. Specifically, the German so called Energiewende (the country’s planned transition to a low-carbon, nuclear-free economy) will be pushed by the decision makers. The German economy has a long way to go to be independent from Russian gas and oil. The war will affect people and businesses all over the world – we see a historical turning point. For Europe and for the whole world.

Doug Glenn, Publisher, Heat Treat Today

Publisher and Founder

Heat Treat Today

The first thing that needs to be clearly communicated is that our thoughts and prayers are with all of those being adversely affected by this war. The loss of human life, personal freedom, and property are the most important impacts of this crisis. Everything else – including what follows in this short column – is somewhat insignificant.

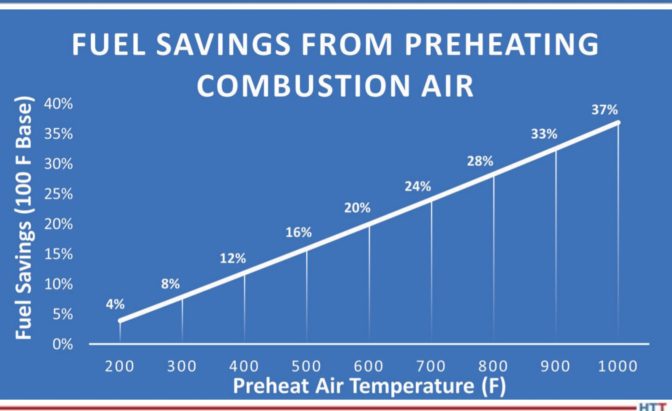

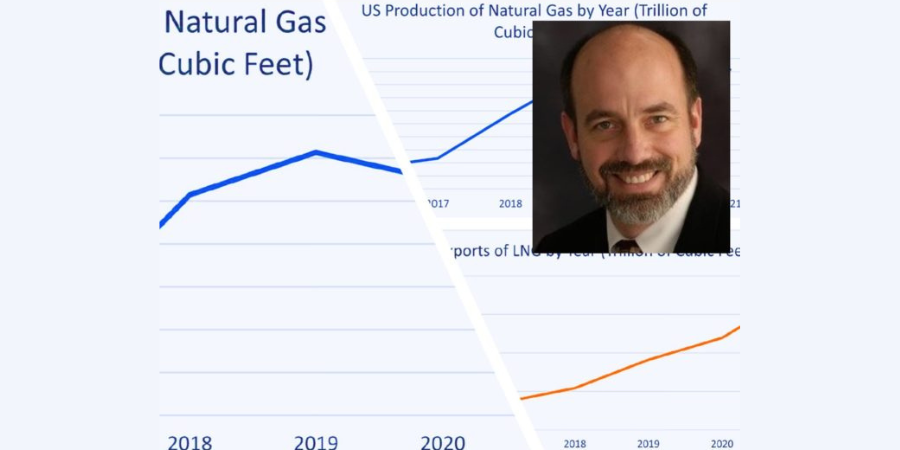

Energy Shortages

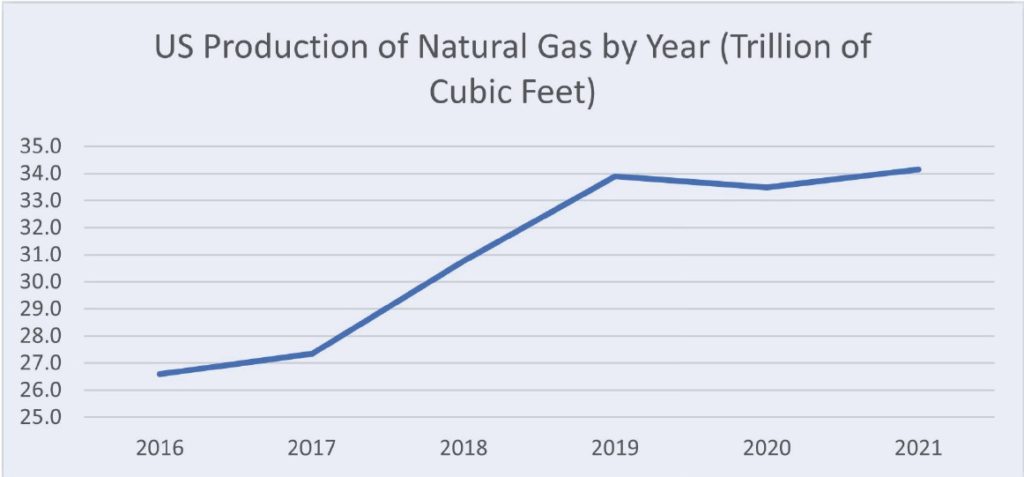

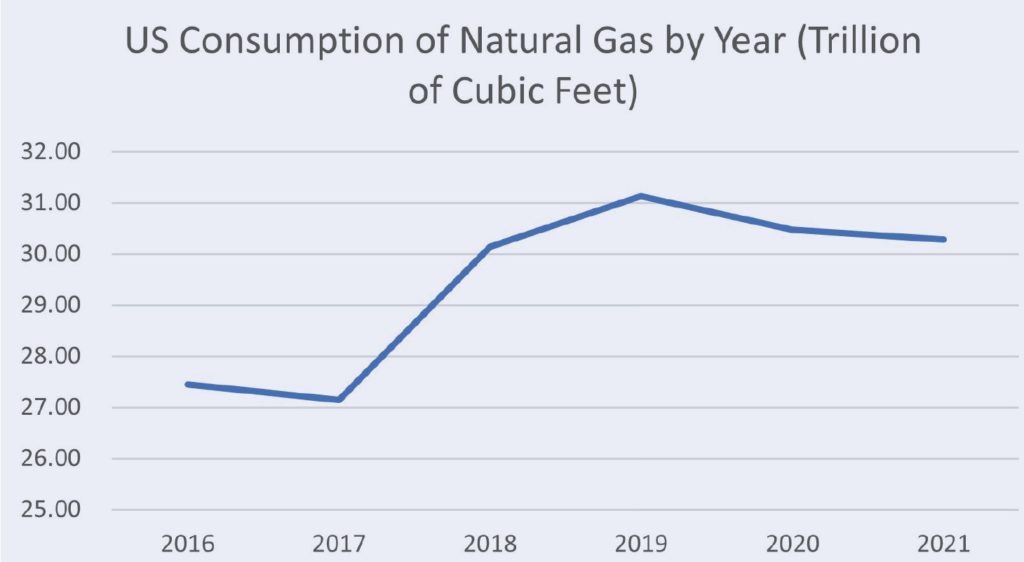

Higher energy prices caused by supply shortages are and will continue to happen. More so today than any time in history, markets are global and what happens halfway around the world will have an impact everywhere. The U.S. has imported nearly 20% of its energy from Russia, and with that supply being cut off, we are and will continue to see rising gas, natural gas, and oil prices.

The U.S. could do more to help ourselves and the world through this crisis, however. Mark Mills from the Manhattan Institute asserts that today, with oil prices at $120 per barrel, the U.S. is producing 1.5 million FEWER barrels of oil than we were last year when oil prices were only $60 per barrel. The energy problem in the U.S. is not fundamentally a lack of energy and it is not a market problem. It is a political problem caused by those who have pushed for “green” at all costs.

Supply Chain

Supply chains are and will continue to be disrupted. Being the largest economy in the world and geographically removed from the crisis, I anticipate that U.S. supply chains may not be as badly hurt as those in Europe, but the disruptions will continue. As we all know, if a manufacturer is missing just ONE PART, the entire end-product is on hold. It is completely unpredictable how and when this will impact the North American heat treat industry, but it is safe to say that it is and will continue taking a toll.

Increased National Debt

Probably the most significant long-term impact of the crisis is the continued irresponsible growth in national debt. Now exceeding $30 trillion, our country does not need a war to incur more debt. But as we all know, there is nothing like war to drive national debt through the roof.

Find heat treating products and services when you search on Heat Treat Buyers Guide.com

Find heat treating products and services when you search on Heat Treat Buyers Guide.com

DUAL PERSPECTIVES: Europe vs. North America Read More »

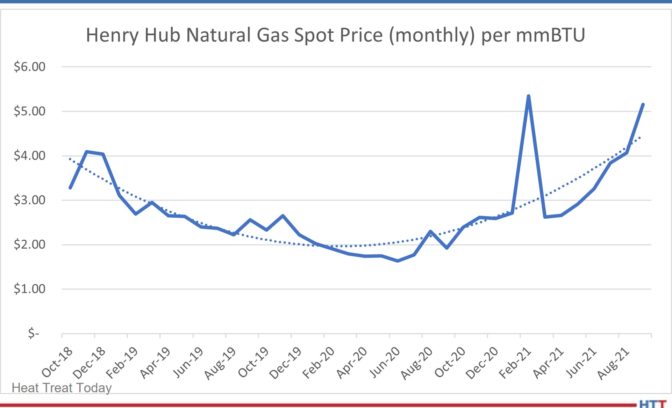

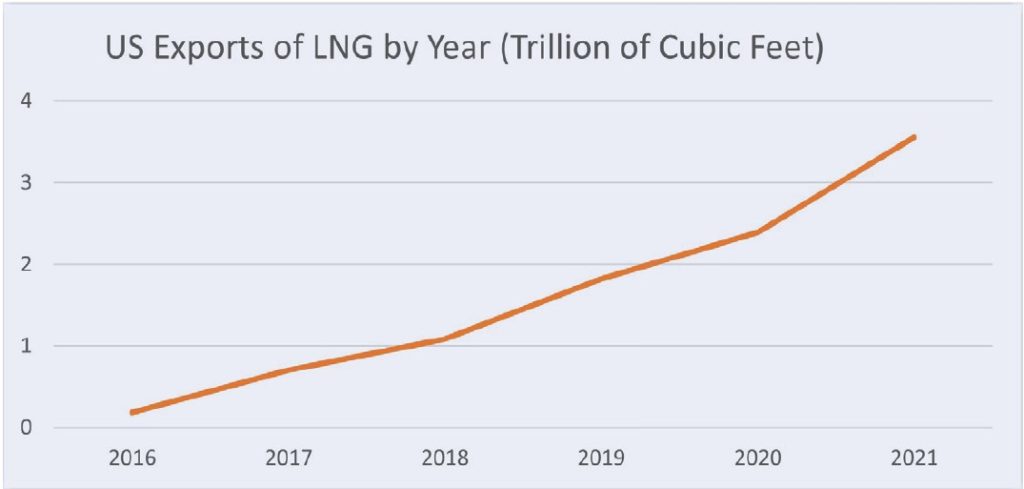

The “Known – Unknown,” the “Undiscovered Country,” the “Movement from cocksure ignorance to thoughtful uncertainty.” It doesn’t matter if you get your catch phrase from Donald Rumsfeld, Star-Trek, or that plaque your mother kept above the kitchen sink, the implication is the same: we really don’t know what the future holds. But, the Unknown of which I speak in this article is natural gas prices.

The “Known – Unknown,” the “Undiscovered Country,” the “Movement from cocksure ignorance to thoughtful uncertainty.” It doesn’t matter if you get your catch phrase from Donald Rumsfeld, Star-Trek, or that plaque your mother kept above the kitchen sink, the implication is the same: we really don’t know what the future holds. But, the Unknown of which I speak in this article is natural gas prices.