The “Known – Unknown”: Preparing Your Facility for Unpredictable World Events

The “Known – Unknown,” the “Undiscovered Country,” the “Movement from cocksure ignorance to thoughtful uncertainty.” It doesn’t matter if you get your catch phrase from Donald Rumsfeld, Star-Trek, or that plaque your mother kept above the kitchen sink, the implication is the same: we really don’t know what the future holds. But, the Unknown of which I speak in this article is natural gas prices.

The “Known – Unknown,” the “Undiscovered Country,” the “Movement from cocksure ignorance to thoughtful uncertainty.” It doesn’t matter if you get your catch phrase from Donald Rumsfeld, Star-Trek, or that plaque your mother kept above the kitchen sink, the implication is the same: we really don’t know what the future holds. But, the Unknown of which I speak in this article is natural gas prices.

This column is a Combustion Corner feature written by John Clarke, technical director at Helios Electric Corporation, and appeared in Heat Treat Today’s March 2022 Aerospace print edition.

If you have suggestions for savings opportunities you’d like John to explore for future columns, please email Karen@heattreattoday.com.

Technical Director

Helios Electric Corporation

Source: Helios Electrical Corporation

Does “What happens in Eastern Europe stays in Eastern Europe” hold true? Unfortunately — no.

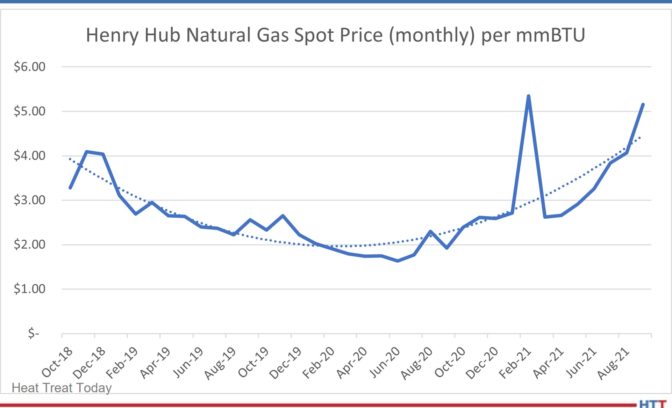

We have learned from recent and ongoing supply chain issues just how interconnected our economy and manufacturing sector is with the rest of the world. The standoff in Ukraine has the potential to impact the world energy markets for years to come, and I suspect this impact will be felt no matter what transpires. I am certainly no expert, but I have a sinking suspicion that our country offered some American methane molecules to Germany to stiffen their resolve to cancel the Nord Stream 2 pipeline. If the EU works to reduce their dependency on Russian natural gas, a significant portion of worldwide exports are removed from the supply side of the equation. From a practical standpoint, these shifts in supply will take some years to achieve, but we have seen a new realization on the part of business and governmental leaders about the importance of robust and reliable supplies of commodities, and manufactured goods and manufacturing capacity. So, less natural gas supply with rising demand equates to higher prices. And as we have discussed previously, liquefied natural gas transportation from the U.S. to the rest of the world is connecting our natural gas market with the world market — and our natural gas price will be affected by consumption and production factors worldwide, just as the price we pay for petroleum oil today is determined in New York, London, and Riyadh — following the consumption patterns in Beijing, Sydney, and Tokyo.

Ok — let’s get back to what we can do in our own facilities to insulate ourselves, to some degree, from unpredictable world events.

Recuperation, or preheating combustion air using the waste heat exiting the furnace or oven is a time proven method to reduce fuel gas consumption. Before we quantify the effect of preheating air, we need to briefly discuss what affects this heated air has on the combustion process. Higher combustion air temperatures are associated with the following:

- Peak flame temperatures are increased. As less energy is used to heat the incoming air, the energy in the natural gas can raise the products of combustion (CO2, H2O and N2) to a higher temperature than would be achieved without combustion air preheating. This can be either beneficial or problematic for a specific application. If the work being heated can accept increased radiation from these higher temperatures — heating rates are improved and throughput increased, but these higher temperatures may reduce the life of furnace components, or, in extreme cases, lead to a catastrophic failure.

- Flame speeds are increased, so the combustion process concludes in less space. Again, this is a double-edged sword, benefiting some and leading to a loss on temperature uniformity in others.

- Total products of combustion required for any quantity of heat input is reduced. Mass flow is especially important in systems where the operating temperature is below approximately 1200°F. If the energy saved leads to a loss in temperature uniformity, it may be a Pyrrhic victory.

- NOx formation is increased. Burner technology has come a long way in recent years to allow for systems to use these higher temperatures without greatly increasing NOx emissions, but the rule of thumb is that by increasing the combustion air temperature from 70°F to 800°F, we basically double NOx formation.

Each of these drawbacks, other than NOx formation, may be a plus rather than a minus for any application. Float glass furnaces (plate glass used in windows) and ingot reheat furnaces are examples of applications where recuperation was applied a century or so ago, at a time where fuel costs where not much of a factor. In both cases, the increased flame temperatures accelerated the heat transfer to either the glass or the steel, increasing production. These applications required furnace temperatures where combustion without preheating would have been impractical — as most of the energy would have been lost in the flues, and very little heat would be available to do any useful work.

What questions should I ask? How much can I save? What is my project’s estimated payback? All are critical questions. To start with, can your existing furnace accept these higher flame temperatures, and can you capture the heat and apply a cost-effective heat exchanger? An example would be a radiant tube furnace. Applying recuperation may require an upgrade in the alloy used in the burner and radiant tube. In direct fired applications, will my uniformity suffer? In general, this is a greater concern at temperatures below 1600°F. As the operating temperatures increase, we can generally expect better uniformity. (I can hear the furnace and burner experts reading this cry “foul,” and they are right, it is not wise to rely on my generalizations — always consult an expert about your specific application.)

How much will it cost? With recuperation, it is best to take advantage of an experienced person’s mistakes, rather than making them on your own. Consult a qualified contractor, OEM, or consultant to help with the application and costs.

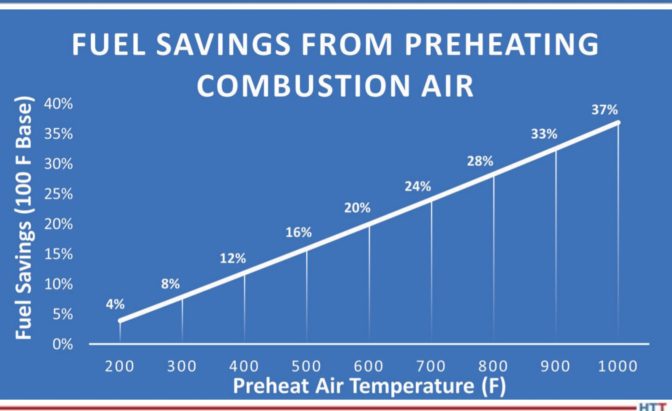

How much can be saved? To answer that question, I provide the above graph. It is not the end all be all but will provide a rough estimate of potential savings. It is for an application with an exhaust temperature of 1600°F operating with 15% excess air.

As we can see, in this application, if we apply recuperation to preheat the air to 800°F, we will save 28% of the natural gas we would otherwise consume.

Before investing your money, an individual analysis of each application is required. This article’s purpose is simply to motivate the reader to invest the time necessary to properly determine, as I mentioned last month, if they have “uncashed checks” lying around their shop.

As always, please let me know if you have any questions.

About the Author:

John Clarke, with over 30 years in the heat processing area, is currently the technical director of Helios Corporation. John’s work includes system efficiency analysis, burner design as well as burner management systems. John was a former president of the Industrial Heating Equipment Association and vice president at Maxon Corporation.

Find heat treating products and services when you search on Heat Treat Buyers Guide.com

Find heat treating products and services when you search on Heat Treat Buyers Guide.com

The “Known – Unknown”: Preparing Your Facility for Unpredictable World Events Read More »