Letter from the Publisher: In Praise of Industrial Heating

Heat Treat Today publishes eight print magazines a year, and included in each is a letter from the publisher, Doug Glenn. This letter first appeared in September's 2023 People of Heat Treat print edition.

Feel free to contact Doug at doug@heattreattoday.com if you have a question or comment.

Publisher

Heat Treat Today

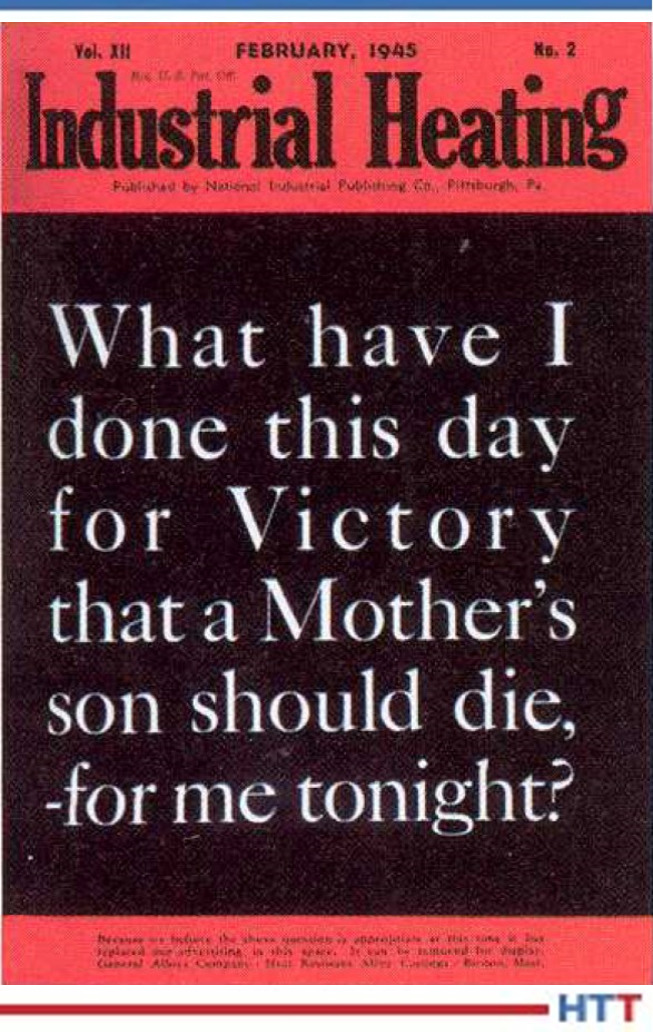

BNP Media, once the largest privately- owned industrial publishing company in the U.S., announced recently they are closing down the legendary heat treat industry magazine, Industrial Heating, effective August 31, 2023.

Some might think this news would be a source of joy in the Heat Treat Today camp, since it is the elimination of a competitive publication. But I can tell you that it is crushing news — crushing for me, personally, having spent 20 tremendous years as the publisher of Industrial Heating from 1994 to 2013, and crushing for the North American thermal processing industry, because a nearly 100-year old iconic magazine no longer exists.

Someone needs to sing the praises and acknowledge the greatness of what was Industrial Heating, so here we go.

In 1924, in the heart of steel city Pittsburgh, Pennsylvania, a gentleman by the name of Stanley Wishoski started Fuels and Furnaces to meet the information needs of the budding steel industry. Fuels and Furnaces was published under that name for seven years and was then rebranded as Industrial Heating in 1931. The publication stayed in the Wishoski family for 64 years, being run much of the time under the direction of Chuck McClelland, son-in-law of Stan Wishoski. Some of you old timers might remember Chuck McClelland or Industrial Heating’s long time editor Stan Lasday. In August of 1988, Business News Publishing Company (now BNP Media) purchased the magazine from Chuck McClelland.

In 1988, Industrial Heating was the number two magazine in the industry behind a publication called Heat Treating, which was at one time owned by Chilton Publishing Company, a company that was, I believe, part of ABC (American Broadcasting Co.). Dave Lurie of Business News Publishing Company saw to it that Industrial Heating grew into the number one spot in the industry in short order. By the mid-1990s, Industrial Heating was the leader.

All through the 1990s and well into the 2010s, Industrial Heating was the kingpin of the North American heat treat industry. During this span, Industrial Heating started Industrial Heating Brazil, Industrial Heating China, and even Industrial Heating India. FORGE magazine, which also closed this August, was founded during this time.

Furnaces North America (FNA) was started by Industrial Heating in 1995. The Metal Treating Institute helped by providing the technical content for the event. Industrial Heating owned and produced FNA ’95 (Cleveland, OH), FNA ’96 (Dearborn, MI), and FNA ’98 (Las Vegas, NV). Then, we sold it to the Metal Treating Institute for $1.00 and an (undisclosed!) percentage of revenue for the next seven events.

For two to three years, Industrial Heating even cooperated with ASM International to publish what is today known as HTPro eNews. The magazine also made the transition from an all-print publishing world to a digital and print publishing world — at least initially. No small feat.

One of the magazine’s most successful products was its annual Buyers Guide, which (just to give you a sense of how successful) often brought in more than $500,000 in ONE MONTH. Annual revenues were in the millions, and profit margins were impressively high. The magazine was enormously successful.

What made Industrial Heating so successful was the people working there. During its heyday, the real “secret” behind the success was people like Jim Henderson, owner and president of Business News Publishing at the time; Dave Lurie, one of the best bosses I’ve ever had and a natural born leader; Kathy Pisano, see my Publisher’s Page about Kathy in Heat Treat Today’s August 2022 Automotive edition; Reed Miller, one of the best and longest-tenured editors the magazine ever had; Bill Mayer, a hard-charging, talented editor; Becky McClelland and Beth McClelland, both granddaughters of Stan Wishoski and daughters of Chuck McClelland; Brent Miller, who had no relation to Reed Miller, but was an outstanding graphic artist; Ed Shaud, father of the actor Grant Shaud from Murphy Brown fame; and Ed Kubel, of ASM fame. Mike Holmes, Kristine Haben, Dick Schiffman, Larry Pullman, Steve Roth, Susan Heinauer, Patrick Connolly, Keith Patrick, and the dozens of administrative and support staff at BNP Media headquarters in Troy, Michigan were also part of this outstanding team. It was this group and their unwavering focus on innovation and on what was best for the customer that made Industrial Heating a powerhouse . . . revenues and profits followed.

In fact, at its peak, Industrial Heating was one of the three largest revenue producers at BNP Media. When I left Industrial Heating at the end of September 2013, it was indisputably the 800-pound gorilla in the North American heat treat industry. Ten years later, it is closing down. Theories about Industrial Heating’s closing are many. Whatever the reason, it is more important to recognize the publication for its dominant place in the North American heat treat market and for its nearly 100 years of existence. Thank you, Industrial Heating and the people who worked there, for the decades of excellent content curation. You truly are “The International Journal of Thermal Processing.” The industry is worse off today than yesterday. It is a sad day.

Find heat treating products and services when you search on Heat Treat Buyers Guide.com

Letter from the Publisher: In Praise of Industrial Heating Read More »

If you’re not a heat treat industry supplier, we encourage you, as a consumer of heat treat products, services, or supplies, to attend the event. The technology that you will see will be eye-opening. Please let us know if we can be helpful getting you to Dusseldorf in June 2023.

If you’re not a heat treat industry supplier, we encourage you, as a consumer of heat treat products, services, or supplies, to attend the event. The technology that you will see will be eye-opening. Please let us know if we can be helpful getting you to Dusseldorf in June 2023.

The shale revolution (mostly happening in America) is the world’s biggest energy revolution. From 2005-2020, the amount of energy provided from shale was TWICE the amount of energy produced from wind and solar arrays combined. This is the largest increase in energy supply in the history of the world, anytime, anywhere. The next closest “revolution” was the Saudi oil fields, but the shale fields have produced nearly DOUBLE the amount of energy.

The shale revolution (mostly happening in America) is the world’s biggest energy revolution. From 2005-2020, the amount of energy provided from shale was TWICE the amount of energy produced from wind and solar arrays combined. This is the largest increase in energy supply in the history of the world, anytime, anywhere. The next closest “revolution” was the Saudi oil fields, but the shale fields have produced nearly DOUBLE the amount of energy.