Specialty Alloys Firm Enhances AM Capabilities with Powder Lifecycle Technology Acquisition

A Pennsylvania producer and distributor of premium specialty alloys recently announced it has acquired a leader in the development and supply of advanced metal powders and powder lifecycle management solutions.

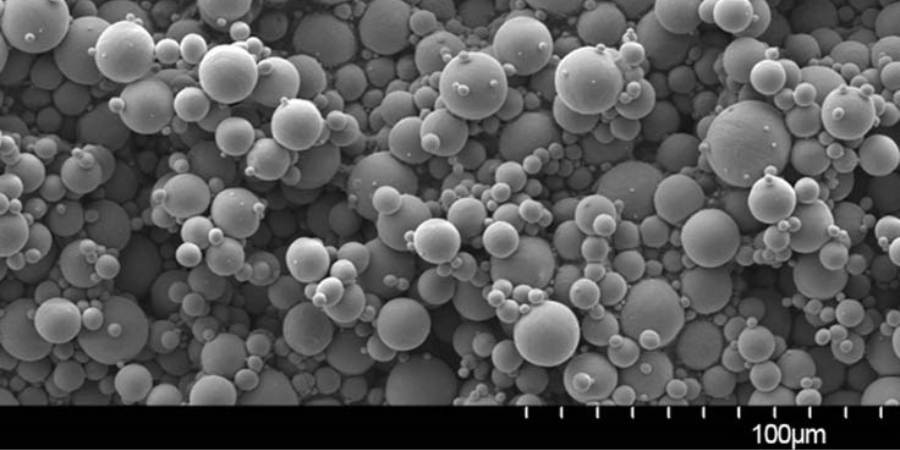

Carpenter Technology Corporation, based in Philadelphia, Pennsylvania, broadens its role as a leader in solutions provider in additive manufacturing with the approximately $81 million purchase of LPW Technology Ltd (LPW), based in Widnes, Chesire, United Kingdom, with additional processing operations near Pittsburgh, Pennsylvania. The acquisition incorporates metal powder lifecycle management technology with quality control and traceability.

Carpenter’s alloy production includes titanium alloys, nickel- and cobalt-based superalloys, stainless steels, alloy steels, and tool steels and is used in applications within the aerospace, transportation, medical, and energy sectors.

“Our aggressive development in key aspects of Additive Manufacturing (AM) demonstrates our commitment to build on our industry-leading position in this space,” said Tony R. Thene, Carpenter’s president and CEO. “The acquisition combines LPW’s metal powder lifecycle management technology and processes with our technical expertise in producing highly engineered metal powders and additively manufactured components.”

Lifecycle management technology is becoming increasingly important to understanding how materials behave before, during, and after production in the powder-bed fusion process. Understanding powder behavior is critical as AM becomes more widely adopted and implemented across various industries.

“LPW’s innovative platforms and enabling technology further solidify Carpenter’s position as a preferred provider of end-to-end next generation Additive Manufacturing solutions,” said Phil Carroll, LPW’s founder. “I’m extremely proud of the accomplishments we’ve achieved at LPW and I’m excited to be part of Carpenter’s continued growth and leadership in AM.”

Photo credit: Additive Manufacturing Magazine