What Will Heat Treating in the Mid-21st Century Look Like?

The Heat Treat Doctor® has returned to offer sage advice to Heat Treat Today readers and to answer your questions about heat treating, brazing, sintering, and other types of thermal treatments as well as questions on metallurgy, equipment, and process-related issues.

This informative piece was first released in Heat Treat Today’s January 2025 Technologies to Watch print edition.

As a very young engineer, I vividly recall our company president had a statue of a three-headed elephant in his office. One head faced forward, one faced slightly to the right, one faced slightly to the left. The moral: looking backwards is not the path forward! Let’s learn more about what the heat treatment industry will look like by the middle of this century.

The Market

A number of market studies and economic forecast models suggest that the global heat treatment market will grow to between 130–150 billion U.S. dollars by no later than 2030 and to around 200–220 billion U.S. dollars by 2040, barring another significant or sustained global economic event. These forecasts assume several minor downturns in the economy of various countries and in manufacturing segments due to economic and geopolitical factors in the coming decades.

Heat Treatment Market Shift

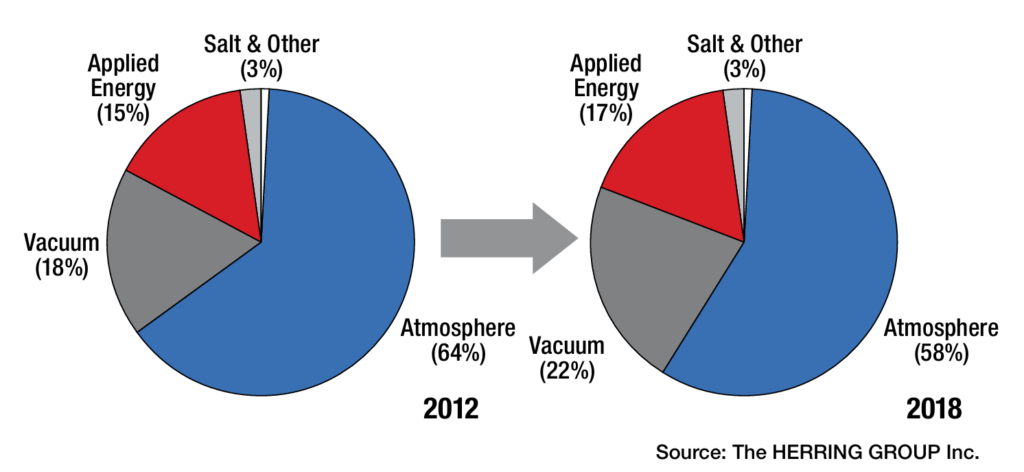

The most significant and fundamental shift that is and will continue is in the makeup of the heat treatment equipment segment of the North American market. What began in the late 1990s and early 2000s as a transition from older, long-established practices and processes to equipment capable of meeting the rapidly evolving demands of technological innovation will continue. Standardization (for cost containment), changes in manufacturing methods and methodologies, and environmental considerations are also fueling this change.

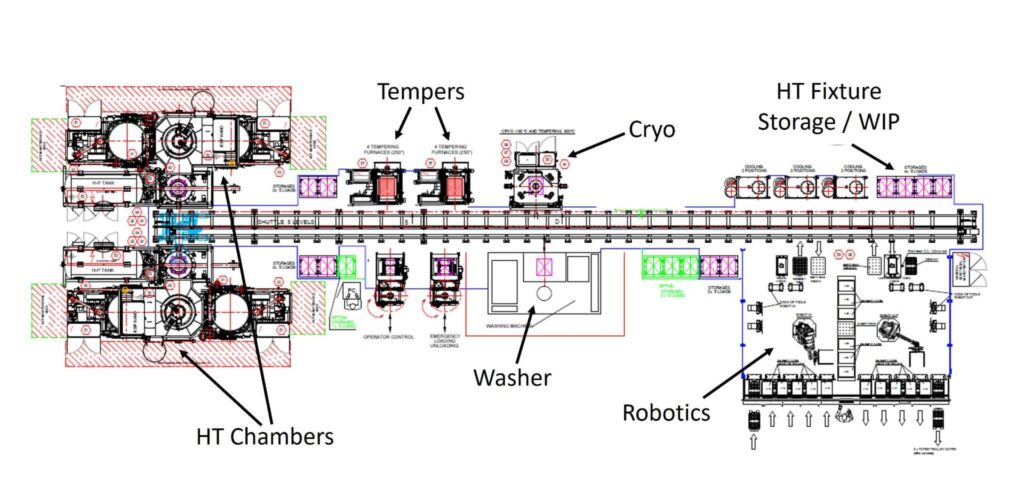

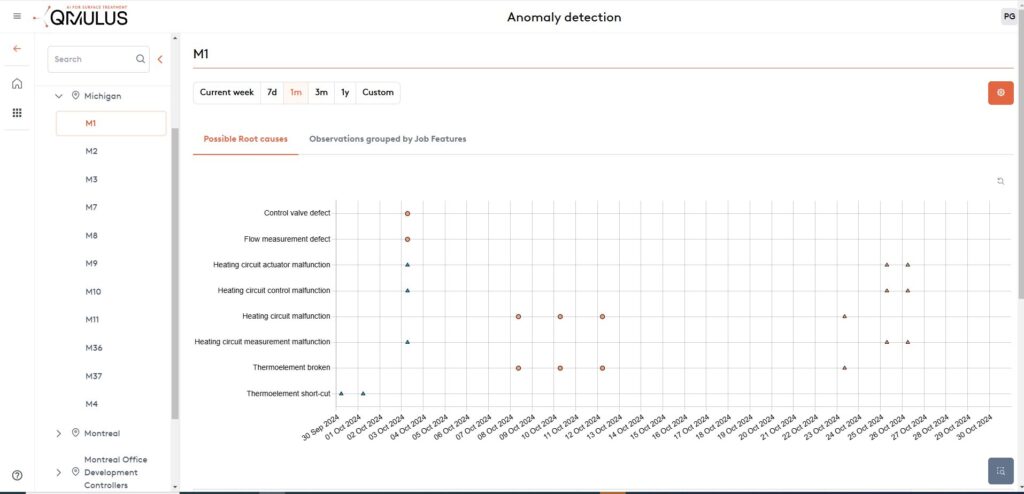

A demand for higher performance products, end-of-life expectations (in some but not all products), an emphasis on systems with single-piece flow or small batch productivity are just a few examples of this change. Other factors such as equipment obsolescence, the need for even higher manufacturing efficiencies, long term operator health and safety concerns, predictive (as opposed to preventative) maintenance, and adaptation to both the speed at which the manufacturing landscape is changing and the type of flexible equipment/processes reinforce these conclusions.

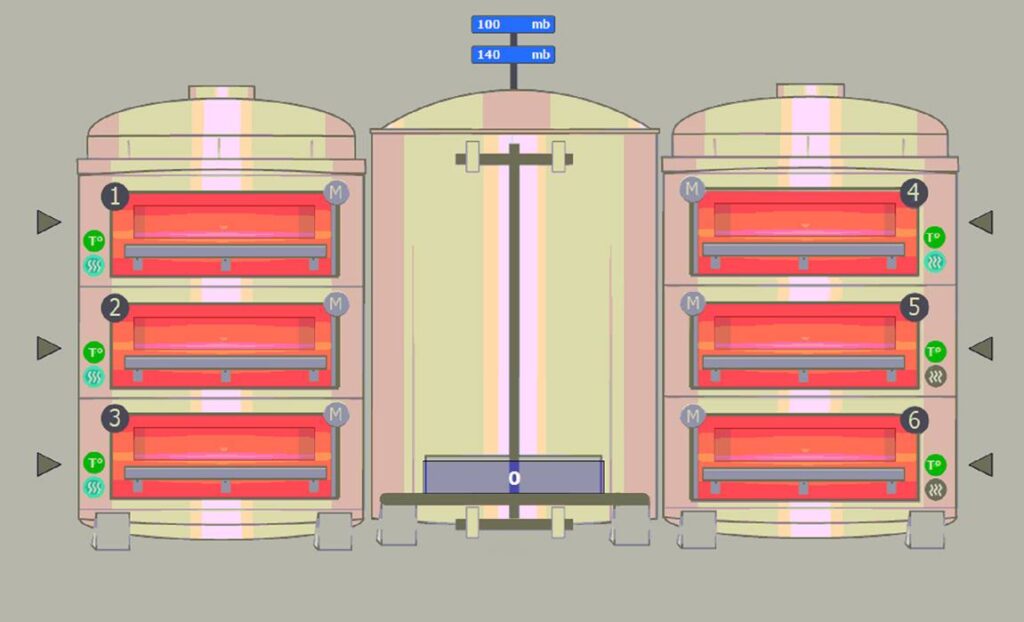

From an equipment standpoint, vacuum furnaces and applied energy systems are and will continue to experience rapid growth at the expense of more traditional atmosphere furnaces. Safety, open flames and emissions of any kind (NOx, CO2, particulates) are driving this change. As such, the dramatic reduction and control of greenhouse gases and the cooling of our planet by the mid-century will be metamorphic. This trend is not only expected to continue but to accelerate (Figures 1–2).

For example, the driving force behind the development, use and integration of vacuum technology into manufacturing is not only due to the fact that it is lean, green, and agile, but also that vacuum technology best addresses the identified needs of the heat treatment industry, namely:

- Energy efficient equipment

- Processing with minimal part distortion

- Optimization of heat treatment processes (especially diffusion-related processes)

- Environmentally friendly by-products and emissions

- Adaptability/flexibility for new and advanced materials

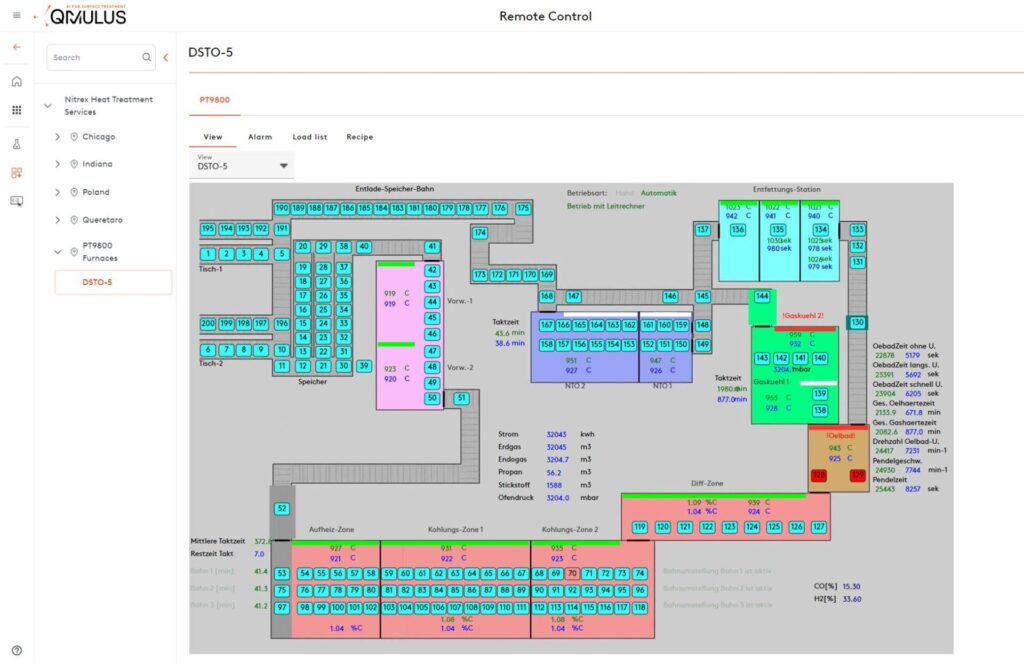

- Process controls incorporating intelligent sensors

- Designs based on heat treat modeling and simulation

- Equipment/process integration into manufacturing

Change — Its Pace and Form

A paradigm shift in the workforce has occurred, transitioning to a vastly more mobile and younger group of individuals relying on the growing role of automation and communication in manufacturing. This shift is principally responsible for accelerating the pace of change in the heat treatment industry, from what has traditionally been a slow moving and slow-to-adapt industry, to one capable of meeting the need for rapid deployment of new products and one that keeps pace with technological innovations.

Moving forward, equipment manufacturers and suppliers to the industry will continue to look at product standardization to maximize profitability, thus driving the industry to “cookie cutter” solutions or, in a diametrically opposite philosophy, looking to provide highly customized solutions, often with risk factors incorporated into the pricing as specialized solutions with high profit margins to application-specific needs.

Technology/Innovation Drivers and Industry Trends

Heat treatment will always be a core manufacturing competency, and as such, decisions will continue to be made to either heat treat in-house or outsource to commercial heat treatment shops. It is significant that the percentage of manufacturers with in-house heat treat departments (80–85%) to commercial (10–15%) heat treat shops hasn’t really changed in the last six decades! The consolidation of companies is a trend that is expected to continue.

What is more prevalent today than ever is the tremendous pressure being exerted on manufacturing from senior management to increase product velocity and lower unit cost. While recalls seem to be a way of life these days, product liability and consume demands for product performance are forcing change, even in the most extreme applications.

As a result, the most identifiable trends in today’s North American heat treatment industry are:

- Growing the manufacturing portion (percentage) of GDP through mobility and adaptability, coupled with more sophisticated and higher paying jobs

- Lowering product unit cost through technology adaptation

- Obsoleting older equipment and technologies and replacing them with innovative new and/or high productivity heat treatment systems. Examples include:

- New materials development allowing for different processing methods and/or lower temperature heat treatments while maintaining environmentally friendly equipment and processes

- Transition of carburizing/ carbonitriding from atmosphere to low pressure vacuum processes with either oil or high-pressure gas quenching, or both

- Use of single-piece heating and quenching of parts and/or small (versus large) batch processing to improve product velocity

- Changes in product materials and/or designs to allow more low temperature atmosphere treatments (e.g., nitriding, nitrocarburizing)

- Use of advanced quenching techniques and quenching technologies to better manage distortion

- Implementing artificial intelligence-based modeling and simulation software capable of equipment control and process optimization

- Implementing the next generation of intelligent sensors, real-time data collection methods and analytics (including cloud-based computing)

- Changing the focus of companies from “generalization” toward “specialization” with respect to products, services, processes (proprietary or unique) and new or innovative technologies to capture greater market share or present opportunities to generate higher profit margins

- Accelerating the implementation of lean manufacturing strategies and applying these strategies to heat treatment:

- Eliminate high labor costs (via automation and controls), simplify operations (i.e., reduce the number of manufacturing steps), and adopt “build to order” strategies.

- Conservation of energy, on-demand part production, shortening of process cycles, and the move toward smaller lot sizes is the order of the day.

- Continuing the transition from heat treatment departments to integrated manufacturing cells

In Summary

It is, and will be for decades to come, a truly magical time in the heat treatment industry. The slow-moving, plodding, three-headed elephant has been replaced by a lean and agile animal — technology. This will not only ensure a greener workplace but an environment of innovation for future generations. And as I am fond of saying about the future, there’s “magic in the aire!”

References

ASM International, Vision 2020. 1999.

Herring, Daniel H. “Esoteric Heat Treatment Industry Critique: 2019 and Beyond.” Industrial Heating, January 2019.

Herring, Daniel H. Atmosphere Heat Treatment, Volume 1. BNP Media, 2014.

Wolowiec-Koreka, Emilia. Carburising and Nitriding of Iron Alloys. Springer, 2024.

About the Author

“The Heat Treat Doctor”

The HERRING GROUP, Inc.

Dan Herring has been in the industry for over 50 years and has gained vast experience in fields that include materials science, engineering, metallurgy, new product research, and many other areas. He is the author of six books and over 700 technical articles.

For more information: Contact Dan at dherring@heat-treat-doctor.com.

For more information about Dan’s books: see his page at the Heat Treat Store.

Find Heat Treating Products And Services When You Search On Heat Treat Buyers Guide.Com

What Will Heat Treating in the Mid-21st Century Look Like? Read More »

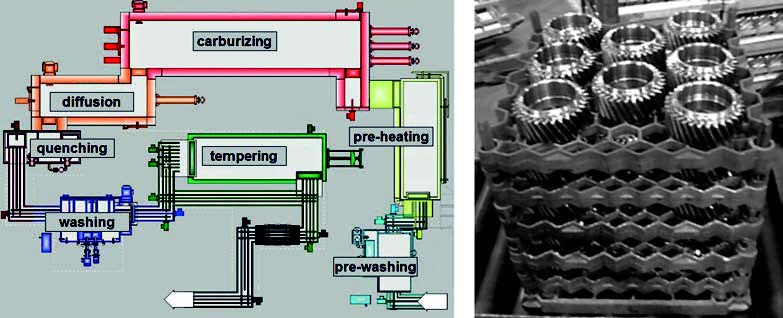

This paper reveals the investigation and conclusions of distortion potentials for case hardening processes. Mainly, the focus was on how the SyncroTherm® concept method compared to conventional case-hardening processes for gears and sliding sleeves.

This paper reveals the investigation and conclusions of distortion potentials for case hardening processes. Mainly, the focus was on how the SyncroTherm® concept method compared to conventional case-hardening processes for gears and sliding sleeves.

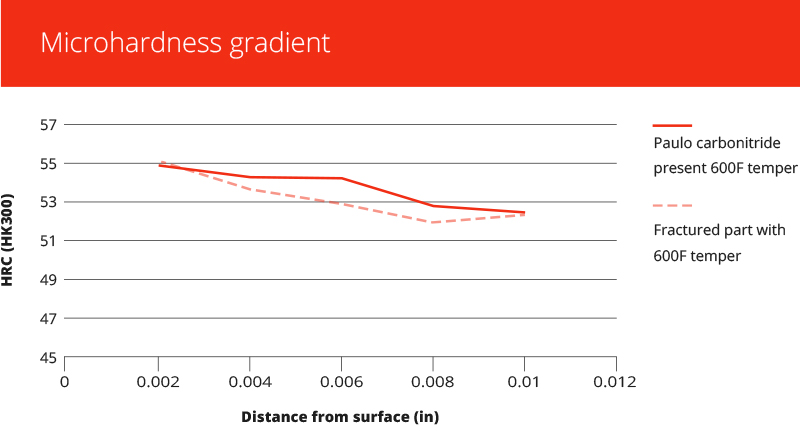

Problems in heat treating result in the loss of valuable time and money. Getting to the bottom of those problems also usually takes time and money to investigate what's happening and how to fix it. What is a heat treater to do?

Problems in heat treating result in the loss of valuable time and money. Getting to the bottom of those problems also usually takes time and money to investigate what's happening and how to fix it. What is a heat treater to do? Low pressure carburizing (LPC) furnaces play an important role in the automotive heat treating industry. During LPC, it is essential that processing temperature stays consistent and critical that the processing time frame is monitored.

Low pressure carburizing (LPC) furnaces play an important role in the automotive heat treating industry. During LPC, it is essential that processing temperature stays consistent and critical that the processing time frame is monitored. Time to brush up on a vacuum brazing furnace, but automotive industry style. Review the terms, parts, function, and more that are involved in a successful vacuum braze for automotive parts.

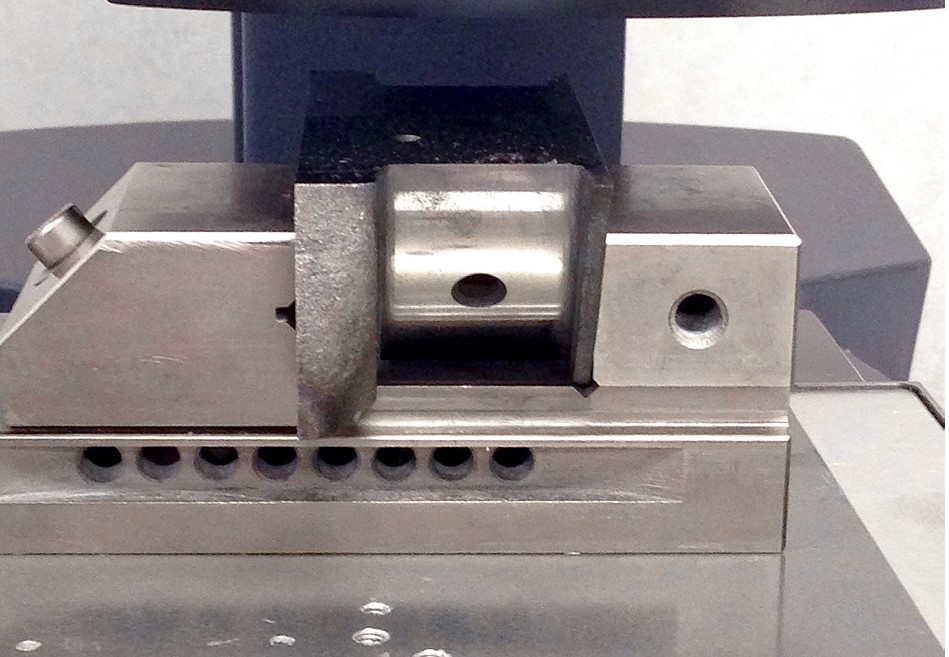

Time to brush up on a vacuum brazing furnace, but automotive industry style. Review the terms, parts, function, and more that are involved in a successful vacuum braze for automotive parts. If you've ever heat treated automotive crank pins, you're probably familiar with at least one type of hardness test that case hardened crank pins are tested against. The big question is, which hardness testing method is better: automated or manual? This article compares these two methods to make and measure Vickers indentations.

If you've ever heat treated automotive crank pins, you're probably familiar with at least one type of hardness test that case hardened crank pins are tested against. The big question is, which hardness testing method is better: automated or manual? This article compares these two methods to make and measure Vickers indentations.