Our readers and Heat Treat Radio listeners will remember a recent episode entitled "Heat Treat Radio #102: Lunch & Learn, Batch IQ Vs. Continuous Pusher, Part 1." Today's Technical Tuesday article is a continuation of this dialog, with Michael Mouilleseaux, a boot-on-the-ground North American heat treat expert from Erie Steel here to answer your questions on the maintenance of batch and continuous pusher furnace systems.

Doug Glenn, Heat Treat Today's publisher, Karen Gantzer, associate publisher/editor-in-chief, join in this Technical Tuesday article.

Stay tuned for a Part 2 continuation of the Lunch and Learn Heat Treat Radio episode, coming to Heat Treat Radio in a couple weeks.

Below, you can watch the video or read from an edited transcript.

General Manager at Erie Steel, Ltd.

Sourced from the author

Introduction to Maintenance

Doug Glenn: We would like to move on to maintenance of the batch furnace and the continuous furnace. What is the cost of maintaining and operating these furnaces?

Michael Mouilleseaux: When they are utilized in a carburizing environment, there is always excess carbon that falls out or precipitates out of the atmosphere, and it ends up as elemental carbon in the bottom of the furnace.

What do you do with that? In furnaces that are using a carburizing environment, the burnout of the furnace is easily the single most important piece of preventative maintenance that you can perform. How is that performed? First, the furnace is vacated; there is no product in the furnace, the temperature is reduced — typically, you want it down around 1500°F or 1550°F — and you introduce room air into the furnace. The room air ignites the carbon. It’s a very primitive operation.

So, what temperature does carbon burn at? It burns at 3000°F.

You need to be very careful. It’s a controlled burn because you can actually damage the furnace through refractory, through the alloy that’s in the furnace, or it can get away. How do you do control it? On one level, you’re just looking at the temperature control. If you have it set at 1550, you’re going to say, “I’m only going to put air as long as the temperature of the furnace does not go up more than 25°F or 50°F.” It’s somewhat dependent upon the piece of equipment and is one of those things that you learn empirically; there is not a hard and fast rule for it.

Then, you can shut off the air. If there is no oxygen, then the source for combustion is taken away and you stop that operation. If you need to do it more rapidly than that, you may need to flood the furnace with nitrogen. Typically, if you have to flood the furnace with nitrogen to do it, you’ve been a little too aggressive in your burnout.

How long do you perform that? The great thing with oxygen probes is that you can utilize your oxygen probe to help you learn when you have burnt out the furnace. You’re not getting an actual carbon atmosphere, but what you do get is a readout from the probe. What you can do is perform the burnout operation until you attain that level and then you know that you’ve done a sufficient job in burning it out. That’s the single most important piece of preventative maintenance that’s done on a furnace used for carburizing.

Doug Glenn: Is that both in batch and in continuous?

Michael Mouilleseaux: Identical, yes.

Doug Glenn: I’ve got a couple other questions about furnace burnouts as someone who’s not a furnace operator. You said that there’s “carbon dropout” in the furnace. I know that in some furnaces, parts of the atmosphere may precipitate onto the coolest part of the furnace. Is that what is happening, or are we talking about carbon powder at the bottom of a furnace?

Michael Mouilleseaux: It is carbon powder, and it becomes more egregious. The powder then begins to accumulate into pebbles, nuggets, and larger size pieces. That’s more problematic. When it is in a powdered form, that is the best.

The question will be: How often do you have to do this? As with everything, the answer is — it depends. It depends on what you’re doing; it depends on how aggressive you are in your carburizing.

In the boost phase, we talked about carburizing at upwards of 1%. As soon as you exceed the saturation level of carbon, you’re going to precipitate out the excess carbon. What is that number? It’s different for every temperature. At 1500°F, it’s .9 or .85; at 1750°F, it’s 1.25. But to attain that, you’re actually putting natural gas into the furnace, and the amount of natural gas that you put into the furnace and its dissociation rate — the rate that it breaks down — can then subsequently be diffused into the parts; all of that comes into play.

With saturation levels of carburizing, there is always some residual carbon that’s in the furnace.

Doug Glenn: You mentioned that carbon burns at around 3,000 degrees. Are you taking the furnace up to that temperature?

The great thing with oxygen probes is that you can utilize your oxygen probe to help you learn when you have burnt out the furnace. You’re not getting an actual carbon atmosphere, but what you do get is a readout from the probe. What you can do is perform the burnout operation until you attain that level and then you know that you’ve done a sufficient job in burning it out. That’s the single most important piece of preventative maintenance that’s done on a furnace used for carburizing

Michael Mouilleseaux: No. The burnout cycle is at 1500 or 1550. You raise that carbon to that level and introduce oxygen, and what you want is a slow burn.

We next think about the systems involved in the furnace. First there is the heating system. In a gas-fired furnace, some critical things to consider are burner recovery, burner adjustment, and the amount of excess air that results in that burner adjustment. That’s a preventative maintenance operation that needs to be performed on a regular basis. It probably doesn’t need to be done daily, but monthly is optimal. If everything is very steady, including the barometric pressure, then you don’t need to do all of those adjustments.

Now, electric furnaces have SCRs that fire the elements, and you have to pay attention to the tuning of those things to make sure that they’re operating at optimum performance. One of the ways that you can do that, in a batch furnace, is if you look at the recovery time.

For example, if you have a load that weighs 4000 lbs. and you put it in the furnace and you know that it takes an hour and a half for the furnace to recover to temperature, but then all of a sudden, it takes an hour and 45 minutes, or an hour and 50 minutes, or two hours, obviously the burners are not producing the same amount of heat. The burners are not pumping the requisite amount of BTUs to achieve that recovery time. Could that be related furnace circulation? Could it be related to the insulation in the furnace? At an extreme, it could. Typically, though, it’s related to burner or SCR tuning.

Those are the kinds of things that are very easy to pay attention to.

"Electric furnaces have SCRs that fire the elements, and you have to pay attention to the tuning of those things to make sure that they’re operating at optimum performance. One of the ways that you can do that, in a batch furnace, is if you look at the recovery time."

Setting up PM Through Controls System

The control schemes in the PLC are typically very robust. So, you can establish a program and the PLC is going to say, “I want to heat it at this rate, I want the carbon potential to be .4%, I want to hold this at two hours at temperature, and then I want to initiate a quenching cycle.” Typically, PLCs are quite robust.

The thing you have to be careful with is obviously not just power outages, but brownouts. Brownouts are when you don’t quite lose all voltage, but you lose some of it. If you don’t have some kind of a filter on the power you can mitigate with, or have an uninterruptable power supply for the PLC, you can damage those things, resulting in some major work on the PLC.

The other part of that is the furnace circulation. We’ve got fans in these furnaces, and we circulate the atmosphere. The primary stages of heating in the furnace are convection, until we get to 1200 degrees. How do we convect the heat? We have the atmosphere in the furnace, the fan circulates, it washes the atmosphere down the radiant tubes, it heats up the atmosphere, the atmosphere comes into contact with the components, and we’re convection-heating the parts.

Once we get to 1200 degrees or more, then the primary method of heating becomes radiant heating. That’s where the radiant tubes are then the primary means of transferring energy. But the fans become very important. Are they balanced? Is the RPM correct? Is the amp reading on the fan? Those are areas to look at.

You have to understand how the furnace operates when it’s healthy — the furnace manufacturer can help you and/or you just learn empirically. For instance, what would it mean if, all of a sudden, I’m drawing much fewer amps on a circulating fan and it’s running very rough? Quite possibly, we’ve lost a fan blade.

Then there is the atmosphere control system. All that we just described is applicable to both continuous and batch furnaces. The furnace needs to be sealed and you want a couple inches of water column pressure — excess pressure — in the furnace relative to atmosphere pressure, since safety is the number one concern.

The atmosphere that we’re talking about in most of these furnaces is endothermic atmosphere. It’s a reducing atmosphere, meaning that it’s combustible. If, of course, we have combustion in a closed vessel, that’s called an explosion.

The reducing atmosphere, in and of itself, is if you look in a furnace that is at anything above 1200 degrees where it’s red, up to 1700–1800 degrees where it’s going to be yellow to white — and there is no flame . . . . People are absolutely amazed when they look in an atmosphere furnace and they see no flame. What you should see is everything in a relative, uniform color. The parts should be a uniform color. If you look at the tubes, they should be a little lighter because the tubes will always be somewhat above the temperature of the parts . . . .

Back to the atmosphere: We want to be sure that the atmosphere stays in the furnace and that we maintain that pressure in the furnace. So, what would be a cause to lower the pressure in the furnace? A door leak or a leak in a fan. It could be, if you have a mechanical handling system, a leak through that system. Those are all places to look.

The PM on that? For maintaining the level of lubrication in the fan bearings, see that they’re cooled so that the outlet temperature of the coolant — be it air or water — should be higher than the inlet temperature; that shows that they’re being cooled.

I can’t tell you an absolute number, but I can say that for the equipment that we have, we have numbers that we’ve developed; we know that if the outlet temperature of the water is 20 degrees higher than it is going in, we’re doing a good job of cooling the bearings.

The door seals in furnaces, typically, are brick on brick. Typically, they use a wedge system to seal the doors in the furnace. But, of necessity, these are wear items. Therefore, in preventative maintenance, you might notice a burnout around a door where you hadn’t had one before. That tells you that atmosphere is leaking out of that door and so a repair is needed in the near future.

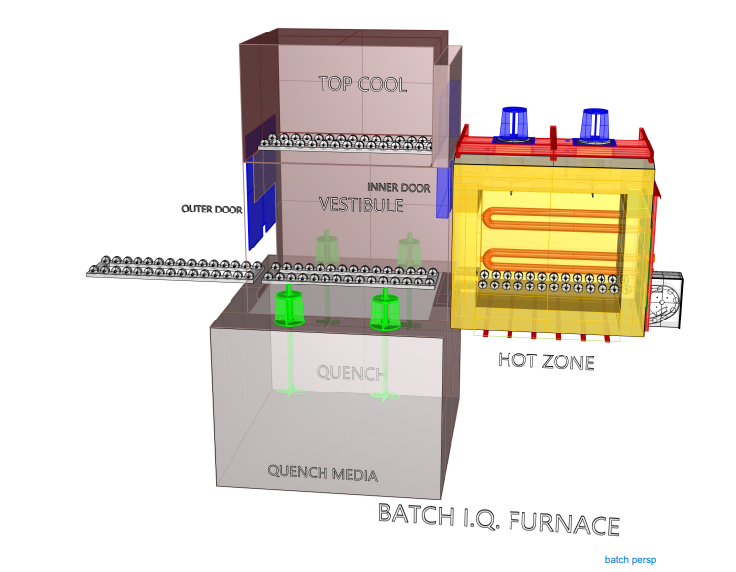

An interesting thing about a batch furnace: Most of them only have one door. So, it’s quite easy — you can open the vestibule and, in a maintenance operation, if you gassed up the furnace, you could see.There is always going to be some atmosphere coming around the door because that’s where the atmosphere goes into the vestibule, but it should be at the top; it shouldn’t be around the sides, and it definitely shouldn’t be at the bottom. It should be very consistent.

That’s one of those things that, again, you empirically learn. You look at it — it’s a visual operation to say what you’re doing.

There are two other systems: First, the quench system. We talked about how critical the quench system is. The RPMs of the prop, the amp draw of the motors for the props — those things should be very consistent. I think they should be monitor and data logged. The reason for that is you want to know when you quench a load that the RPMs of those props are what you have set it for. When you introduce a load into the quench, the amp draw is, of necessity, going to increase. That’s because you’ve put something in the path of the quenchant so, in order to maintain that flow, you’ve increased the amount of work that it takes to rotate those props.

That’s the kind of thing that you want to monitor. If the amp draw is changing, that means that there’s something in the quench system. Could it be the bearings? Could it be the motor? Those are some things that you’d need to take a look at and be certain of. Obviously, the props need to be in balance; you don’t want any vibration in them.

Doug Glenn: This is also true on the continuous furnace. You’ve got three or four green props in the batch furnace, and it would be the same in the continuous furnace.

Maintenance of Quenchant

Michael Mouilleseaux: Also, there is the maintenance of the quenchant. I’m of the belief that the quench should be continuously filtered. I’m not a fan of batch filtering. I’ve been doing this long enough that I’ve done that, and it just isn’t successful. Quite possibly there are operations that allow it.

If you’re carburizing, you’re going to have particulate in the quenchant because that same atmosphere precipitation of carbon finds its way into the quench. It’s going to be on the parts, it’s going to be on the trays, it’s going to be dragged in there. So, you have this particulate carbon in the quench and it acts as a catalyst to break down the oil.

One way to extend the life of the oil is to make sure that you’re continuously filtering that out. People say 50 microns or 100 microns or 25 microns. Experientially, I’m going to say that it’s going to be 25 microns. If you have a 100-micron filter, that’s great for getting the pebbles out of the quench or the scale, if that were to be an issue with your customer’s parts, but that’s not sufficient to filter out the particulate that’s going to be of the size that’s going to catalyze the breakdown of your quenchant.

Doug Glenn: I assume that if you’re providing for some sort of continuous filtering of your quench, that’s built into the quench structure. The quench tank is built for that, right, and you’re continually flowing it through this filter?

Michael Mouilleseaux: I’m not going to say that no manufacturers offer sufficient quench filtering, but I am not aware of anyone that offers a quench filtration system that’s sufficient. Most of these things end up being standalone. You want to draw the quenchant from the bottom of the tank in one quarter, you want to put it through a series of filters, and you want to put it back into the furnace at the opposite end of the quench tank.

I can say with certainty, that a batch furnace which has not been filtered well, if you remove the quenchant from the furnace after six months — definitely after 12 months — of using it in daily carburizing, you’re going to take 55-gallon drums of sludge out of the furnace, and the sludge is essentially carbon that’s mixed in with the oil.

For that same furnace, with a sufficient quench filtration system, there will be little pockets in the four corners of the quench tank, but that’s about it.

CQI-9, Nadcap and all of those standards have a requirement for monitoring of quenchant. One of the monitors should be particulate because that lets you know how good a job you’re doing in filtering.

Having done it properly, one can say, “Well, I have to replace my quench oil,” — fill in the blank — “once a year, once every six months, once every two years.” Properly maintained and filtered, the quenchant does not have to be replaced very often.

You’re going to drag out a little oil on every load. You want to let the load drip so that you’re not taking that precious quench oil and just putting it in the wash and washing it off. But in a batch furnace, you could have a couple hundred gallons a month to four hundred gallons, depending on the size of the furnace, of add-back that you’re putting in there. Is that sufficient to maintain all of the additives that are in the quenchant? Is that something that you need to monitor? Typically, the manufacturer can do that for you. You get monitoring and you see what the quench speed is, what is the viscosity, flash – all of those important pieces of information.

Now, it doesn’t come for free. A filtration system is costly, and the filters are costly. A year’s worth of quenchant is five years’ worth of filters. In my mind, that’s a good tradeoff.

Karen Gantzer: So, Michael, when the process is filtering the quench, does this happen during production downtime?

Associate Publisher/ Editor in Chief

Heat Treat Today

Michael Mouilleseaux: No, it’s done continuously. Even when the furnace is not running on the weekend, you’re still filtering the oil. You’re going to be taking 20-50 gallons out of the quench tank but you’re putting it right back in. It just passes through filters.

Some people have utilized centrifuges. It’s a very successful way of filtering out carbon particles in oil. The caveat on that is you don’t want the oil above 140 degrees. If you get the oil above 140 degrees and for every 20 degrees you go up, you start doubling the oxidation rate of the oil.

In high-temperature oil, we do a fair amount of modified marquenching. We do it in closed canisters. The seals must be temperature-tolerant, but it is very successful.

The last part is going to be the quench heating and cooling. Typically, at the first part of the week when you’re starting up the furnace or if you’re going from operation A to operation B and it requires a higher temperature quenchant, you’re going to use either gas or electric elements that are going to heat it. Those things need to be monitored so that they’re available when you need them. The last thing that you want to do is start out the week and find out that the quench heaters don’t work; then, you’re trying to find a couple of dummy loads that you can heat up to put into the quench to heat up the quenchant before proceeding with operations.

Then, of great, importance is quench cooling. In petroleum-based quenchants, you’ve got a flashpoint of 400 degrees plus or minus — could be 350, could be 450, depending upon the quenchant that you’re using. You don’t want the temperature of that oil to approach that flashpoint. You do that by using a quench-cooling system. It’s a big radiator. You’ve got a pump, and you set it when you want the pump to go on. You pump the oil out to the quench coolant, and when it comes back, once you’ve attained what your temperature is, then you stop.

Doug Glenn: I’ve got a couple quick questions on this. First, is the quench heater an immersion tube?

Michael Mouilleseaux: Yes. Gas-fired tubes and gas-fired units are very small u-tubes that go into the quench tank. Electrical units have got elements that are tolerant to that.

Doug Glenn: Typically, you’re using those because you’re actually using the quenchant and always putting hot things into it, so once the quench fluid is up to temperature, it’s not a problem. You’re using that quench heater just to get the thing up to temperature. So after that, most of the time, you’re using the cooler to keep it cool, correct?

Michael Mouilleseaux: Absolutely. That’s a control scheme. The last thing that you want to do is set the quench heater so that it’s within five degrees of setpoint and set the quench cooling so that it’s within five degrees of setpoint — then, the temperature just sits there, with heating and cooling fighting each other. You’re heating and cooling oil unnecessarily. You want to give yourself some bandwidth on that.

Material Handling System

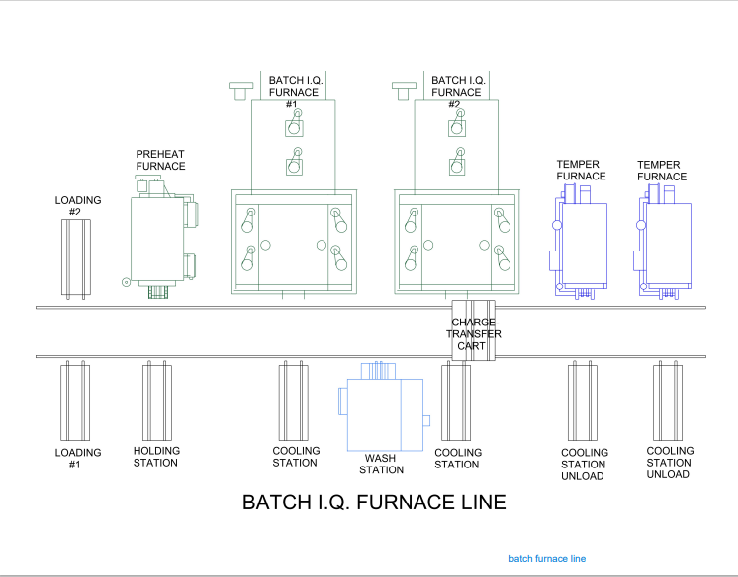

Last is going to be the material handling system. In the batch furnace, many have what we call a “rear handler.” We saw the cart and it would push the load into the vestibule, the inner door would open, and it would push the load into the furnace. It’s always preferable to push hot loads, not to pull on them. The reason is that the base trays are alloy and the compressive strength is much higher than the tensile strength is. If you’re pulling on loads, you’re going to break trays.

Once the load is in the furnace, you would have a rear handler so when the cycle is terminated and the inner door opens, you would have a mechanism — it may have a flat bar that’s half the width of the tray — that actually pushes the load into the quench vestibule.

There it’s pushed by the charge car and the inner door is open. That same handler, from the charge car, pushes it into the furnace. Now, when the cycle is terminated, there is a handler in the rear of the furnace that pushes it into the vestibule for quenching.

The exception is right here: When it’s taken out of the vestibule, typically the charge car goes in and grabs it and pulls it out. But, at that point, you’re at 100 or 200 degrees so, at that temperature, you have no material effect upon the strength of the alloy.

Doug Glenn: Okay, the motion it took it from the tray on the left inside is going to push it in and then the next step it’s also going to push it into this “hot zone,” correct?

Michael Mouilleseaux: Yes.

Doug Glenn: But what you’re saying is, when it’s coming out of the hot zone, there’s probably a mechanism on the far righthand side of the hot zone that’s going to push it back. Nothing is going in to pull it out because it’s hot.

Michael Mouilleseaux: Extended reach cars put the load into the vestibule and then put it into the hot zone.

There are some rear handlers that, rather than being a simple push function, have a dog mechanism that allows them to go and get the load in the vestibule and pull it into the furnace. Personally, I am not a fan of that; I like the extended reach car because when you’re pushing something, it is very easy to determine if you’ve put it in the right location. If you grab a load and pull it, you could lose the attachment on that load and then it’s not put exactly where you want it to be.

You can put amp meters on these things so that the amount of force that the motors require to pull in or push out a load. The one thing you need to be cognizant of is that it’s going to take more power — a higher amp draw — to push a 4000-pound load than it is a 2000-pound load. Once you understand what that is, you can monitor these furnaces and then they start making sense to you.