This is the second of three articles by metallurgist Marc Glasser on three individual heat resistant alloys. This article will feature RA330®. Please submit your questions about heat-resistant alloys for Marc to editor@heattreattoday.com.

RA330® is a nickel alloy containing 35% nickel, 19% chromium, and 1.2% silicon. Over the years, it has become one of the most widely used wrought heat-resistant alloys due to the combination of its versatility, availability, properties, and cost-effectiveness.

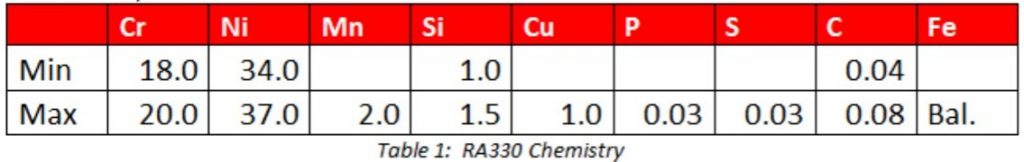

The Chemistry of RA330

The chemistry of RA330 is shown below in Table 1.

There are several important benefits to this alloy including:

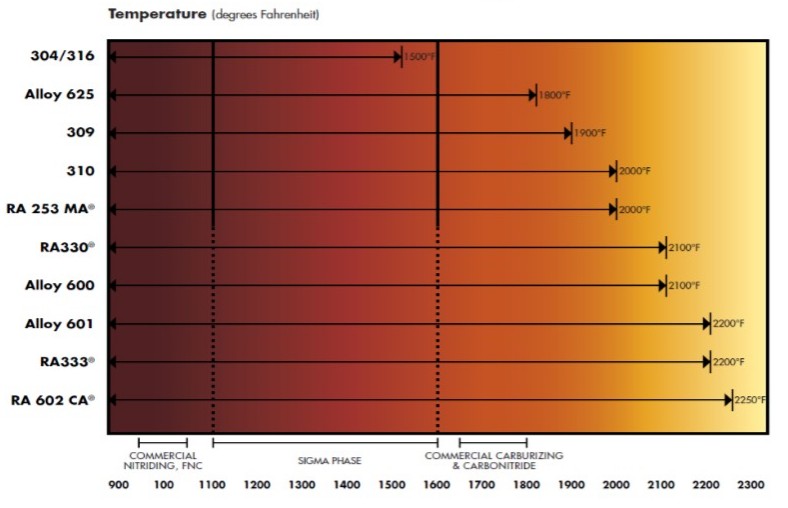

- Oxidation resistance up to 2100°F

- Usable creep resistance up to 1850°F

- Utility up to 2100°F when there are no loads applied and some deflection can be tolerated

- Resistance to many heat treating atmospheres including carburizing and nitriding

- Sufficient nickel content to prevent sigma phase formation and embrittlement

The oxidation resistance of various alloys is shown in Table 2 below¹.

The oxidation limit for RA330 is higher than that of any stainless steel, comparable to alloy 600, and only exceeded by nickel alloys with much higher nickel content.

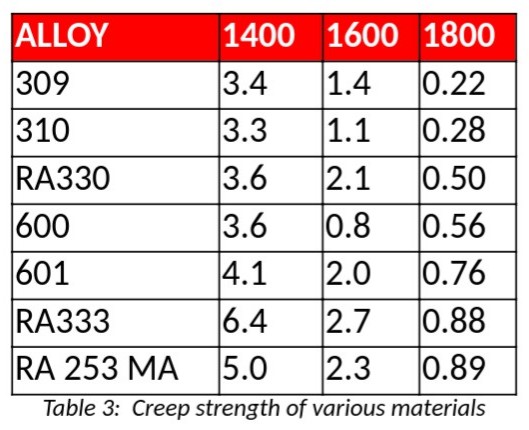

RA330 Creep Strength

Table 3² shows the creep strength required to produce 1% strain in 10,000 hrs.

The creep strength of RA330 is better than all heat-resistant stainless steel grades except RA 253 MA. It is comparable to alloy 600 but less than the higher nickel alloys 601, RA333, and RA 602 CA. When comparing the economics of RA330 with those of the more expensive nickel alloys, RA330 often has enough creep strength for many heat treating applications and is often the most economical option. There are companies who use RA330 above 1800°F and sometimes as high as the 2100°F oxidation limit. They compensate for the very low creep strength at these temperatures by using braces such as gussets or supports. These supports may be made of ceramic or a different alloy with significantly higher creep strength at this temperature.

Strength Variables and Value

One of the excellent attributes of RA330 is its ability to resist the various atmospheres used in surface or case hardening operations. Thermodynamically, the formation of nickel carbides and nitrides are not favored. With 35% nickel, RA330 has sufficient nickel content to resist carburization, nitriding, and combinations of both. The alloy is not immune to surface hardening, just resistant. The length of resistance time is a function of the process and process variables. For example, field experience shows that 310 muffles used in carburizing atmospheres can completely carburize in as little as 1 month, especially at high temperatures. After that, the material is brittle and can rupture easily. Often, the usable life will be between 1 and 3 months depending on process temperature. A corresponding RA330 muffle under the same atmosphere will last up to 1 year.

Stainless steels are subject to sigma phase formation and embrittlement. Sigma phase is an intermetallic phase that consists of iron and chromium. It precipitates between approximately 1100 and 1600°F. Sigma phase does not embrittle materials at these relatively high temperatures, but at room temperature, sigma phase can reduce charpy impact values to single digits. One sudden impact can cause catastrophic failure. RA330, with 35% nickel, has enough nickel to prevent sigma phase formation.

Applications of RA330

RA330 is available from stock in many product forms. In addition to the traditional plate, sheet, and round bar, RA330 is also available in expanded metal, pipe, and hexagonal nuts. Round bar can quickly be turned into threaded bar. The ability to draw on all these items from stock make RA330 the ideal alloy for maintenance and repair.

RA330 is resistant to thermal fatigue. This property lends RA330 to be the wrought alloy of choice for alloy fixtures and baskets that require quenching a least once a day.

For all of these reasons, RA330 is often an excellent choice for heat treating applications. It has good oxidation resistance, good resistance to case hardening atmospheres, no sigma phase formation, and thermal fatigue resistance. It is available from stock in many forms and sizes. RA330 may not always be the best solution, but often it is the solution that works best.

One of the few atmospheres in which RA330 is not a good choice is sulfur. Like other nickel alloys, the nickel forms a nickel-sulfur intermetallic at a low temperature. In such environments, a lower nickel stainless steel such as 309 or 310 is often a better choice.

RA330® is a trademark of Rolled Alloys.

1. Glasser, Marc, “Selecting an Appropriate Heat-Resistant Alloy,” Industrial Heating. September 2014: 59-65.

2. Condensed from “High-Temperature Environments: Alloy Properties,” https://www.rolledalloys.com/technical-resources/environments/high-temperature/

Marc Glasser is Director of Metallurgical Services at Rolled Alloys and is Heat Treat Today‘s resident expert in process metallurgy, heat treatment, materials of construction, and materials science and testing.