![]()

For heat treat operations, use of hydrogen comes with questions about price-point, safety, and storage or delivery. Read this case study to learn how a manufacturer with in-house heat treat, Riverhawk Company, contended with these questions and decided to meet stringent production requirements for pivot bearings by leveraging on-site hydrogen and a hydrogen furnace.

This original content article was written by Marie Pompili, a freelance writer, for Heat Treat Today's May 2023 Sustainable Heat Treat Technologies print edition.

For companies using hydrogen furnaces for heat treating operations, questions always surface surrounding the provision of the necessary hydrogen. Should we have it delivered in cylinders? Do we have the room outdoors for a large storage tank? Can we generate it ourselves? For Randy Gorman, maintenance supervisor at Riverhawk Company, the overriding question is always, “How do we handle hydrogen safely?” The ultimate solution the company chose was the installation of an on-site hydrogen generator. How and why the in-house heat treater came to that conclusion is an interesting story.

Making a History

Source: Nel Hydrogen

Located in New Hartford, NY, Riverhawk Company was established in 1993 as a value-added provider of hydraulic tooling. The company quickly grew from a “buy and assemble” operation to a manufacturer with 14 CNC machine tools, 21 conventional machines, and all the necessary peripheral devices, tools, and software. Through a period of smart acquisitions and the development of new product lines, Riverhawk became one of the leading manufacturers of tensioners, powertrain couplings, and accessories for the turbomachinery industry; the instrumentation product line of legacy torque and vibrations measuring instruments; and the Free- Flex® pivot bearings, which are very well known in high performance industry sectors.

Pivot Bearing Line Requires Improved Heat Treat Abilities

The Free-Flex® pivot bearing line is the focus in this heat treat/hydrogen story. Riverhawk purchased this line from Goodrich in 2004. It is the same product that was developed by Bendix more than 60 years ago. In fact, many of the original part numbers are the same, and the manufacturer strives to maintain the quality and performance characteristics that Bendix established more than six decades ago. Many of the manufacturer’s clients have been purchasing flex pivots for long-running applications, some of which are 25 to 50 years old.

Source: Nel Hydrogen

If a product line could talk, the flex pivots could share some tales and compelling accounts about all it has seen and done in the world’s most critical and sophisticated applications — many in the military, commercial aerospace, outer space, industrial robotics, medical, clean rooms, information technology, semiconductors, and many more. In all of these challenging sectors, clients are well-known and demand exacting results.

Shortly after integrating the pivot line into its existing production processes, it became clear that the company needed to improve its heat treat function. After researching several options, Riverhawk purchased a new Camco batch hydrogen furnace.

The pivot line consists of flat springs crossed at 90° and supporting cylindrical counter-rotating sleeves. Standard Free-Flex® pivots are made from 410 and 420 stainless steel; however, certain special material compositions include 455 stainless, Inconel 718, titanium, and maraging steel. During the manufacturing process for the flexure bearings, Riverhawk uses the batch atmosphere heat treat furnace to braze the springs to the body halves using a braze alloy, and to simultaneously heat treat certain components in the assembly. The atmosphere used for the heat treating and brazing is a 100% hydrogen atmosphere — chosen because it is universally applicable to all the different metallurgy used for the flex pivots.

The Tension: Delivered vs. On-site Hydrogen?

The use of a batch atmosphere heat treat furnace requires that the hydrogen atmosphere be flushed from the furnace with inert nitrogen when a finished batch is unloaded and a new load is added. Likewise, the furnace must return to inert atmosphere again with nitrogen after the new load is added, and before hydrogen is again injected; hence, hydrogen is used in a batch-wise fashion. The function of the hydrogen atmosphere is to prevent oxidation of the metal surfaces, and to promote fluxing of the braze alloy during the thermal cycle.

Until 2009, Riverhawk used hydrogen-filled cylinders to provide hydrogen to their batch heat treat furnace. Each run of the furnace would use several cylinders of hydrogen. Increases in production rates required careful management of hydrogen gas supply to the furnace. Running out of hydrogen mid-run could sacrifice a whole batch of nearly completed parts.

In 2009, the company elected to move away from hydrogen cylinders and transition to a hydrogen supply approach less disruptive to their production process. The choices were either bulk stored hydrogen or on-site hydrogen generation. After extensive consideration, they chose a model H2 hydrogen generator from Nel Hydrogen because the zero-inventory hydrogen generation saved the company money as compared to the cost of permitting, construction, and compliance for bulk stored hydrogen approaches.

The approach that was not chosen — delivered, stored bulk hydrogen — was unappealing for several reasons. Chief among these were the capital cost of the hydrogen storage infrastructure, the requirement for permitting for the necessary hydrogen storage, the accompanying project schedule risk for permitting, the continuous compliance issues with stored hydrogen, and the price volatility of delivered hydrogen that would have made cost accounting more difficult.

“The state and local regulations were likely necessary; however, there was a lot to wade through to become compliant,” said Gorman.

Finding the Best Way

Fast forward 14 years to today and Riverhawk is once again analyzing its approach to handling its hydrogen requirement.

“The H2 model generator that we have has served us well for 14 years, several years beyond the typical life of a cell stack,” said Gorman. “But we need more capacity and redundancy due to the increased demand for our Free-Flex® products and to cost-effectively mitigate the risk of a hydrogen generator issue, leaving us without the use of our furnace.”

The company decided to go with a model H4 hydrogen generator from Nel Hydrogen, which doubles their capacity with two cell stacks and the capacity for three if and when needed. The new system features the same footprint as the former H2 model, which is important to them, and they are even gaining floor space as they will eliminate the number of cylinders formerly stored nearby. The additional free space to move about also appeals to Gorman’s top mandate for safety.

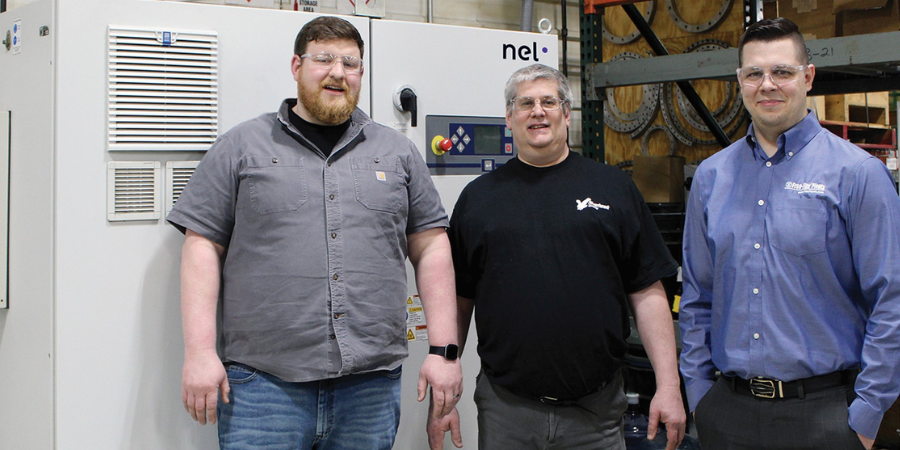

Josh Suppa — engineer of the Pivot Department at Riverhawk — has had hands-on experience with this particular generator series (pictured above). “The maintenance of it is easy, and if there ever is a rare issue, Nel is quick to respond either in person or if it’s something that they can walk us through, they take all the time we need to resolve the matter and get us back online quickly. From a product line and customer satisfaction perspective, we cannot take the risk of our heat treat operation to go down for long. It’s that integral to our success. It’s essential, really, and one of our core competencies.”

Source: Nel Hydrogen

Choosing On-Site Hydrogen Generation

Looking back on the initial decision to generate on site, one of the important issues that Riverhawk and Nel personnel had to determine was the most cost-effective configuration of the hydrogen generator and ancillaries to supply the hydrogen required for thermal processing. Had the manufacturer used a continuous furnace such as a belt furnace, then the calculations would have been easy, as the flow rate required would have been level and continuous. Instead, the batch furnace required more complex calculation because the hydrogen flow rate varies depending on the stage of the furnace cycle: fast hydrogen flow to fill the furnace, then slow to maintain the atmosphere, then no flow during parts removal and during loading. Additionally, there were many factors that affected the precise furnace cycles employed, including the size of the pivots in each batch, the number of parts loaded, and the specific metallurgy of the flex pivots in the batch. Overall, the cycle times can vary between 6 and 12 hours per batch.

It is important to seek out a knowledgeable hydrogen partner in this endeavor to specify exactly what’s needed, no more and no less. For heat treat applications, users generally would want compact equipment, extreme hydrogen purity, load following, near-instant on and instant off, and considerable hydrogen pressure that make it flexibly suited for a variety of thermal processes.

By combining on-site hydrogen generation with a small amount of in-process hydrogen surge storage if needed, on-site hydrogen generation can be used to meet the needs of batch processes, such as batch furnaces. By carefully choosing generation rate and pressure, and surge storage vessel volume, the process can provide maximum process flexibility while minimizing the amount of hydrogen actually stored.

In practice, client priorities such as minimum hydrogen storage, or lowest system capital cost, or highest degree of expandability, or least amount of space occupied can be met by choosing the specific hydrogen generator capacity and surge storage system employed for any particular production challenge.

In this case study, the optimum solution chosen was based on lowest capital cost and operating cost (including maintenance) while preserving the maximum possible expandability for production increases, and safety. These sound like common reasons and may be yours as well. Success continues at Riverhawk with the arrival of the new H4 generator in the coming weeks.

About the Author: Marie Pompili is a freelance writer and the owner of Gorman Pompili Communications, LLC.

For more information:

Visit nelhydrogen.com and riverhawk.com.

Find heat treating products and services when you search on Heat Treat Buyers Guide.com

Guide.com