Source: Edinburgh Sensors

Source: Edinburgh Sensors

Heat treaters know the essential role they play in making high quality -- and, sometimes, just simply useable -- metals. In today's feature article, read about how furnace atmospheres provide protection and controlled material modification; why endothermic process of gas composition must be carefully controlled; and how the endothermic process of gas composition is measured in furnaces.

An excerpt:

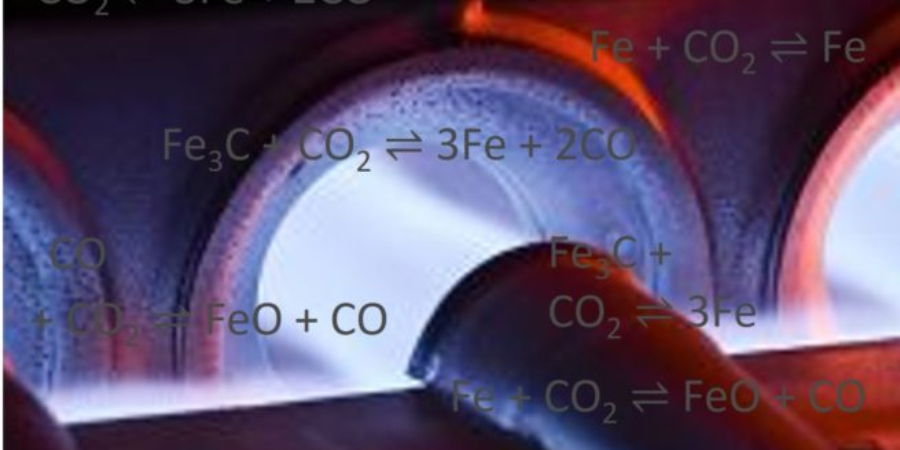

"The main objective of a protective furnace atmosphere is to prevent undesired decarburization, hydrogen embrittlement, oxidation, surface bluing, and soot formation. For the desired metal treatment to be successful, the gas composition must be carefully monitored and strictly controlled. Measuring the concentrations of CO, CO₂, H₂, H₂O, N₂ and CH₄ in the generated endothermic gas atmosphere can help ensure that both the endogas generator and the furnace are operating correctly and prevent any undesired reactions."

Read more at "Endothermic Process and Heat Treatment Furnaces – CO and CO₂ Control Considerations"