Fives, an international industrial engineering group for silicon steel processing lines, will receive high efficiency burners with low emissions. This will help the company as they fulfill recent orders involving the supply of annealing and pickling lines as well as annealing and coating lines to Chinese steelmakers.

Fives, an international industrial engineering group for silicon steel processing lines, will receive high efficiency burners with low emissions. This will help the company as they fulfill recent orders involving the supply of annealing and pickling lines as well as annealing and coating lines to Chinese steelmakers.

The burners were designed and supplied by WS Wärmeprozesstechnik, and with their FLOX® process, Fives will be able to manufacture using the strictest emission values without SCR (selective catalytic reduction) treatment for their furnaces for silicon steel. This was necessary as China’s steelmakers have been demanding combustion technology with lowest NOx emissions in order to meet climate-related goals.

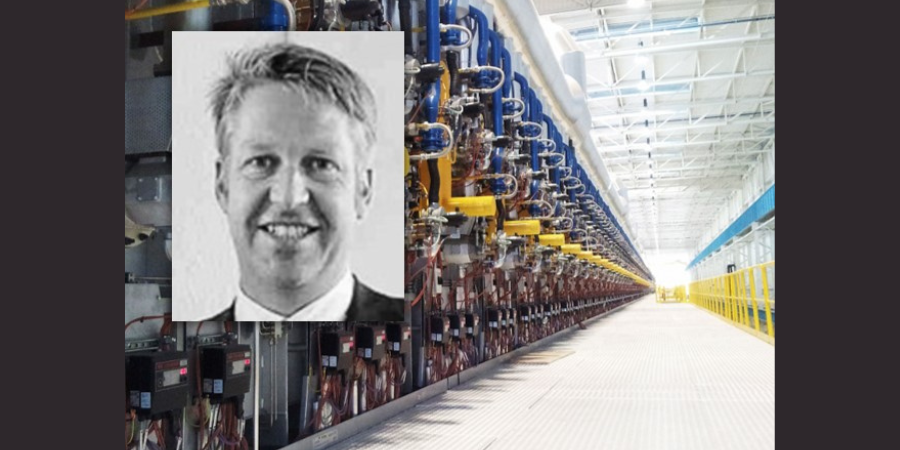

President

WS Wärmeprozesstechnik GmbH

The silicon strip line with FLOX® burners from WS (pictured above) will assist Fives in their current orders as well as their continued design and supply of machines, process equipment, and production lines in various sectors. These sectors include steel, aerospace and special machining, aluminum, automotive and manufacturing industries, cement, energy, logistics and glass.

"It is our ambition at WS," states Dr.-Ing Joaching G. Wünning, president of WS Wärmeprozesstechnik GmbH, "to provide solutions for all continuously operated strip lines which can reliably attain NOx emissions well below 100 mg/Nm³, with simultaneously high combustion efficiency over 80% and which are, already today, suited for a future with green combustion gases."