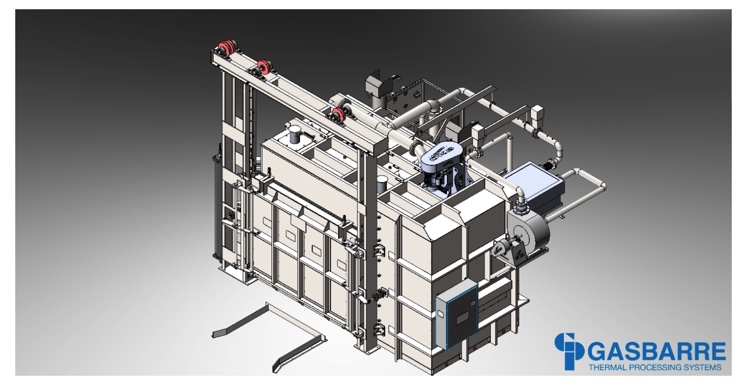

A manufacturer in the aerospace market with captive heat treating capabilities received a custom built atmosphere tempering furnace. With a working load size of 84” wide, 42” deep, and 60” tall, coupled with a max load weight of 6,000 pounds, the furnace is specifically designed for the customers' key manufactured components.

The electrically heated furnace, shipped by Gasbarre Thermal Processing Systems, has an operating temperature range of 350℉ to 1600℉, and passes uniformity at +/- 10℉ per AMS2750E. The system is equipped with custom controls, including Eurotherm brand temperature controlling instrumentation and an Allen-Bradley PLC and HMI.

Automatic atmosphere control is included for running under nitrogen, argon, and/or a hydrogen blend. Custom designed atmosphere cooling systems are installed to reduce overall cycle time. The equipment configuration also enabled the customer to switch from pit furnace style processing, which eliminated infrastructure costs and maintenance concerns.