VP Global Sales

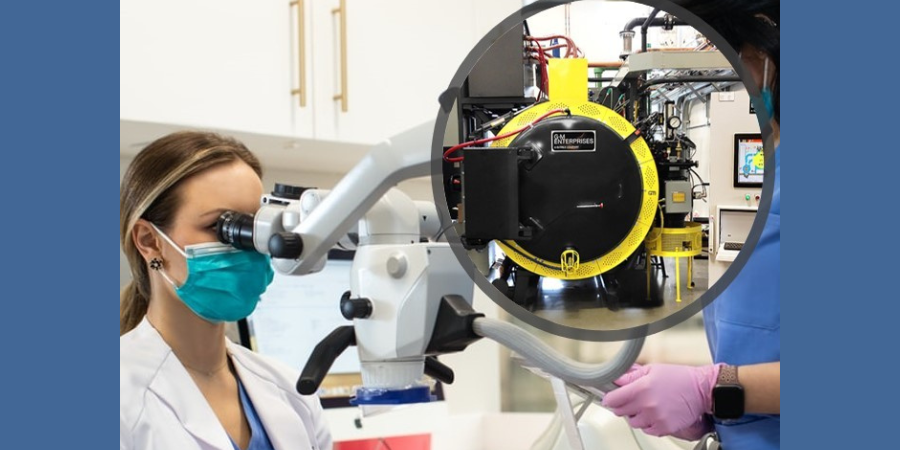

Nitrex and G-M Enterprises (Source: Nitrex.com)

A medical device manufacturer has acquired a vacuum furnace that will bring heat treating in-house, reducing lead time and improving process control. The application is for the heat-treatment of steel dies used in the company’s plastic and metal injection molding operations.

The vacuum furnace is the first purchase from G-M Enterprises, a Nitrex company. G-M Enterprises completed the installation at the company’s newly expanded greenfield facility. The turnkey solution features a horizontal front loading vacuum furnace G-M model HVF 101-(I)XB with 6-Bar internal quench capabilities and a work area of 18” x 18” x 24” (457 x 457 x 610 mm), with an all-metal furnace construction. The system is part of the company’s metal injection molding operations.

"We are proud of continually maintaining G-M Enterprises’ long-standing relationship with the medical industry," said Michel Frison, VP Global Sales, Nitrex and G-M Enterprises, "providing solutions that aid in improving the affordability and accessibility of high-quality healthcare."