NexGen Advanced Fuel Systems (AFS), a gas turbine component overhaul facility that is a company of Allied Power Group, ordered a new vacuum furnace to help increase their capacity and reduce turnaround time for their heat treating and brazing operations. It is built specifically to heat treat land-based turbine equipment with attention to specific cooling specifications required by the company's clients.

NexGen Advanced Fuel Systems (AFS), a gas turbine component overhaul facility that is a company of Allied Power Group, ordered a new vacuum furnace to help increase their capacity and reduce turnaround time for their heat treating and brazing operations. It is built specifically to heat treat land-based turbine equipment with attention to specific cooling specifications required by the company's clients.

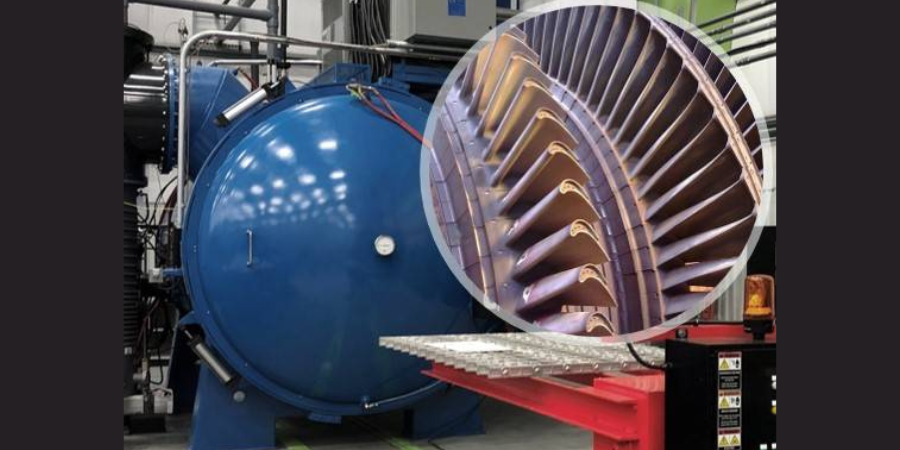

Built by Solar Manufacturing, the furnace features a Solarvac® Polaris Control System and a graphite hot zone accommodating loads up to 48" wide x 48" high x 72" deep. The furnace has a maximum load weight capacity of 6,000 pounds.

The furnace achieves a vacuum level of 10-5 Torr, and reaches a maximum operating temperature of 2400°F. A 300 HP gas fan will allow NexGen to quench a load from 2150°F to 1000°F in just three minutes, using only 2-bar.

Source: Solar Manufacturing

"The interface makes running the furnace easy for operators of all skill levels," states Mark Dion, president of Nexgen-AFS, and the general manager of Allied Power Group Combustion Technologies. "For furnace installation and operation, Solar provides knowledgeable engineering and support staff. The Solar furnace has a robust design, with some nuances such as stainless steel internals, brass fittings, made in USA valving, and in our case, a beefed up blower allowing super-fast cooling abilities. . . . Nexgen hopes business growth supports purchasing a second Solar vacuum furnace."