Discover how to keep your furnace in prime working order as Fred Hamizadeh, director of Global Manufacturing Services- Heat Treat & Facilities Equipment, of American Axle & Manufacturing and keynote speaker at Furnaces North America 2020 (Virtual) Trade Show, outlines the essential attributes of effective maintenance practices for industrial heat treating equipment.

Discover how to keep your furnace in prime working order as Fred Hamizadeh, director of Global Manufacturing Services- Heat Treat & Facilities Equipment, of American Axle & Manufacturing and keynote speaker at Furnaces North America 2020 (Virtual) Trade Show, outlines the essential attributes of effective maintenance practices for industrial heat treating equipment.

This article will be featured in Heat Treat Today’s upcoming FNA Trade Show issue in early September.

Director of Global Manufacturing Services- Heat Treat & Facilities Equipment, American Axle & Manufacturing

I recall great advice from my first boss, Bob Williams, of Williams Industrial Service: He said to me early on that if the maintenance people are happy with your equipment, you’ve designed a good furnace. Combining many years of my OEM furnace manufacturing experience with my current position allows for a perspective that is useful to both American Axle & Manufacturing (AAM) and our OEM suppliers.

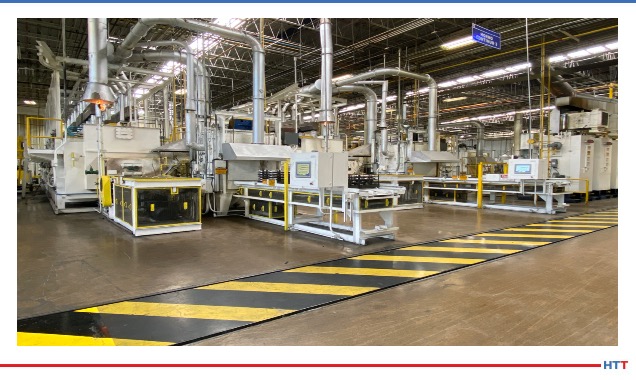

American Axle & Manufacturing can trace its history to the early 20th century and was comprised of the five General Motors plants, purchased by an investment team led by our co-founder, Richard E. Dauch, in 1994. Heat treating has been a core competency of the AAM manufacturing system since the inception of the company. AAM uses conventional gas carburizing and tempering as well as various induction processes in the manufacturing of all drive-train components. These components include: case hardening of gears and pinions; induction hardening of shafts, CV joint and balance shafts; and sintering of powder metal. Our metal-forming product business unit uses induction heating to forge and manufacture a large variety of automotive components. As one of the largest captive global heat treaters, AAM’s carburizing equipment varies in size and style, from batch to single and multirow pushers. Induction equipment cells also vary from single spindle to multi spindle, fully automated hardening and tempering lines.

“While we remain open to all new developments and advances in technology, it does not provide suppliers with an open checkbook. We must maintain a balance between high technology, reasonable CPU, component performance improvement, and reliability. “

An integral part of AAM’s quality process is the maintenance and reliability of production equipment including the heat treat equipment. To remain current with latest CQI-9 requirements, all maintenance intervals are scheduled, followed, and monitored by the company leadership. All AAM facilities have an advanced maintenance team that performs most of the day-to-day requirements and responds to all emergency cases.

Maintenance requirements must be considered early on during equipment selection, procurement, design, and manufacturing. AAM has specifications that heat treat manufacturers must follow to allow safe and fast maintenance to occur regularly without requiring equipment to be removed from production. As a minimum, sufficient access points within the equipment are essential. A preferred location would be to have access from the plant floor; otherwise, safe platforms must be provided. All hazards such as heat, electricity, and stored energy must be eliminated or locked out. A detailed LockOut TagOut (LOTO) system diagram allows maintenance to be performed safely. Use of our recommended parts list ensures that we have common components for speedy repairs within our stores.

Today, we look for equipment that has the following features to allow extended mean time between failures (MTBF), provided regular scheduled maintenance is completed:

- Equipment built to AAM’s specifications for heat treat equipment. These specifications are designed based on our needs and best practices as well as supplier capabilities and regional presence.

- Use of common components within company provided parts list

- Use of domestically available and reliable material and components for equipment built in various regions of the world for ease of replacement. Otherwise, the use of U.S. or European brands with global presence is preferred.

- Use of standard equipment design to allow common spare parts that can be shared between plants. This standard design will also provide equipment interchangeability and allow maximized equipment utilization based on plant loading.

- Use of common control equipment and sensors. We utilize two brands of process controls. Our electrical systems use AAM Controls Architecture specifications that allow all plant control engineers the ability to troubleshoot, repair, and place equipment back into production rapidly.

- Use of highest-grade cast or wrought nickel-chromium grade components to insure long MTBF. This is one area that must be observed closely during the bidding process.

- Use of brick lining for all carburizing zones. This eliminates the carbon burnout issues associated with ceramic fiber lining.

- Use of reliable, dependable, and global suppliers. Our need to maintain interchangeability and versatility to maintain high utilization rates require suppliers to have presence in North and South America, Europe, and Asia. Same is true for component suppliers. Rapid response to issues is critical for our operations and most of our suppliers have met this requirement.

- Enforcing a maintenance schedule that allows for maximized production while allowing time for burnouts and maintenance. Maintenance and burnout schedules are established a year in advance. These schedules are communicated and balanced with production requirements. This period is not only required for performing needed maintenance but should be used to plan the next maintenance activities.

- Detailed LOTO tags to pinpoint all sources of energy that need to be locked out to perform safe maintenance.

- Detailed inspection of equipment for safety, maintenance, and function prior to shipment from supplier.

- Provide training for engineers, technicians, and operators in safety operation and maintenance of the equipment by the manufacturer.

- For large and complex equipment, monitor force and cycle time historically as early indicators of maintenance requirement.

While there are some new developments and advancements in the maintainability of equipment using the latest digital technologies such as Mobile Maintenance Assistance by Aichelin, more development needs to occur to allow integrated maintenance, record keeping, spare parts ordering, and monitoring. Digital archives of system drawings and manuals must be available for a maintenance technician at point of use. Additionally, video recordings of training sessions can be maintained at the equipment for training new associates.

The future of heat treat will include more advances in induction processing, austempering, and further development of liquid quench capable LPC equipment. Over the last 30 years, many new processes have been introduced into the market but were unable to justify eliminating conventional gas carburizing and induction hardening. While we remain open to all new developments and advances in technology, it does not provide suppliers with an open checkbook. We must maintain a balance between high technology, reasonable CPU, component performance improvement, and reliability.

About the Author:

Fred Hamizadeh, a mechanical engineer and 32-year veteran of the heat treat industry, is the director of Global Manufacturing Services-Heat Treat & Facilities Equipment, at American Axle & Manufacturing. The majority of his experience has been focused on the OEM side of heat treating with Surface Combustion and Williams Industrial. For the last 14 years, Fred has worked on the consumer side of heat treating with AAM.

For more information, contact Fred at Fred.Hamizadeh@aam.com