Project Manager

NITREX Poland

LinkedIn.com

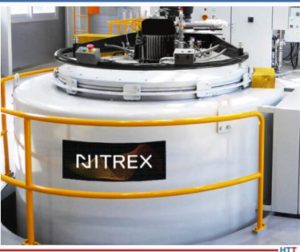

Arslan Aluminyum recently added three new extrusion presses to its production, increasing the demand for nitriding their dies and necessitating a large-capacity nitriding system for the biggest press. The system will nitride H11 and H13 dies that extrude aluminum profiles for the construction, renewables, joinery, furniture, and equipment sectors.

When the plant upgraded, the new nitriding system furnace was required to help double the production capacity. Arslan selected a NX-1015 pit furnace designed to treat workloads up to 4400 lbs that are 39″x59". The collaboration with Nitrex and Arslan Aluminyum started in 2011, when the family-run business purchased an NX-812 turnkey nitriding system.

Source: Nitrex

“The people of Arslan['s] high regard for our products and company has helped us tremendously in getting new contracts in Turkey.” commented Marcin Stokłosa, project manager at Nitrex.

Pictured above: collaborators from Turkey. Photo Source: Nitrex.