The automotive industry is going electric — electric vehicles are a popular choice for consumers. To continue sustainable efforts for a healthier planet, heat treaters need to seriously consider energy recovery technologies for their equipment and processes. In this Technical Tuesday article, Harb Nayar, founder, president, and CEO at TAT Technologies, examines the use of combustible burner technology (CBT), specifically CBT technology retrofitted on conveyor furnaces that utilize some level of combustible produced by synthetic or generated atmospheres, and that have peak temperatures above 1400ºF (760ºC).

This informative piece was first released in Heat Treat Today’s August 2024 Automotive print edition.

Annealing, brazing, and even powder metal (PM) sintering, metal injection molding, and additive manufacturing offer the automotive industry components with the precision to meet their demanding standards. For example, the nature of PM manufacturing produces minimal waste, both from a material and an environmental perspective. But most in-house and commercial heat treaters fail to capture and reuse energy or convert emissions with environmentally unfriendly pollutants by use of efficient and available gas-neutralizing equipment. These devices capture and thermally combust hydrocarbons, carbon monoxide, and noxious gases such as ammonia.

The reality is that rather than just neutralize these emissions, heat treaters can use them to heat their parts, even before preheating. The focus of this article is to examine the use of combustible burner technology (CBT) and more specifically, CBT technology retrofitted on conveyor furnaces for processes that has the following:

- Have peak temperature above 1400ºF (760ºC).

- Utilize some level of combustible (e.g., H2, CO, and CH4) produced by synthetic atmospheres (e.g., N2-H2) or generated atmospheres (e.g., Exothermic, Endothermic and dissociated ammonia).

Recovering Latent Heat Energy

A typical conveyor furnace found on the shop floor has three distinct zones, a preheat zone, a high heat zone, and a cooling zone. Since it is desirable in these units to have a forward atmosphere flow (toward the entrance end of the furnace and opposite the direction of part travel), combustibles emitted while processing the parts exit at the entrance and are typically burned off before entering the room or exhaust system. Often, flames can be seen burning at the front of the furnace.

Combustible burner technology, aka lubricant burner technology (LBT), is a thermal technology that was originally developed to address issues in the PM industry (Figure 2). This technology can be supplied with or retrofitted on the front of a conveyor furnace to recover latent combustion energy from combustibles (e.g., H2, CO, CH4) or hydrocarbon vapors (e.g., wax lubricants used for PM parts). The energy can be reused to heat parts before entering the preheat zone. This means that the preheat zone itself can be significantly shortened.

Retrofit Example — PM Sintering Furnace

PM processing is very specific and often more difficult to adopt compared to other continuous atmosphere furnaces. Given the large percentage of PM parts used by the automotive industry, it offers a good example of how heat treaters can achieve energy and cost savings via energy recovery technology.

A Close Look at the Process

Sintering is commonly performed in continuous atmosphere furnaces. In the sintering process, powder metal is combined with a binder, often solid wax (Acrawax®) or stearate-based lubricants are used in the compaction process to make green parts. Delubrication (aka delube, debindering) then takes place in the preheat section of the furnace. There are three phases during PM sintering:

Typical door-to-door time varies between one to five hours, depending upon the material being sintered.

The most common atmosphere used in sintering processes is N2 with 7–20% H2. In other shops, the atmosphere used is Endothermic gas, which has (approximately) 40% H2, 20% CO, with the balance primarily N2 or dissociated ammonia (DA) with a composition of 75% H2 and 25% N2. In some sintering operations, a mixture of DA and N2 is used.

The atmosphere with all the combustibles travels from the high heat section to the preheat section and finally exits from the front of the furnace where the various pollutants are burned off before entering the exhaust system. The total amount of combustibles varies between 10% and 50% depending on the type of atmosphere and material being sintered.

For example, CBT units have been installed for the delubing of tungsten-based alloy parts prior to sintering in high temperature pusher furnaces.

Capturing Latent Energies

During the PM sintering process, users can capture this latent heat to transfer this energy into the green parts prior to the preheat section. The following are approximations of the latent combustion energy available:

- H2: approximately 0.1 KW per cubic foot of H2 or 0.35 KW per cubic meter of H2

- CO: approximately 0.12 KW per cubic foot of CO or 0.4 KW per cubic meter of CO

- Wax lubricant: approximately 5 KW per lb. or 11 KW per kg of lubricant going into the furnace

How CBT Works

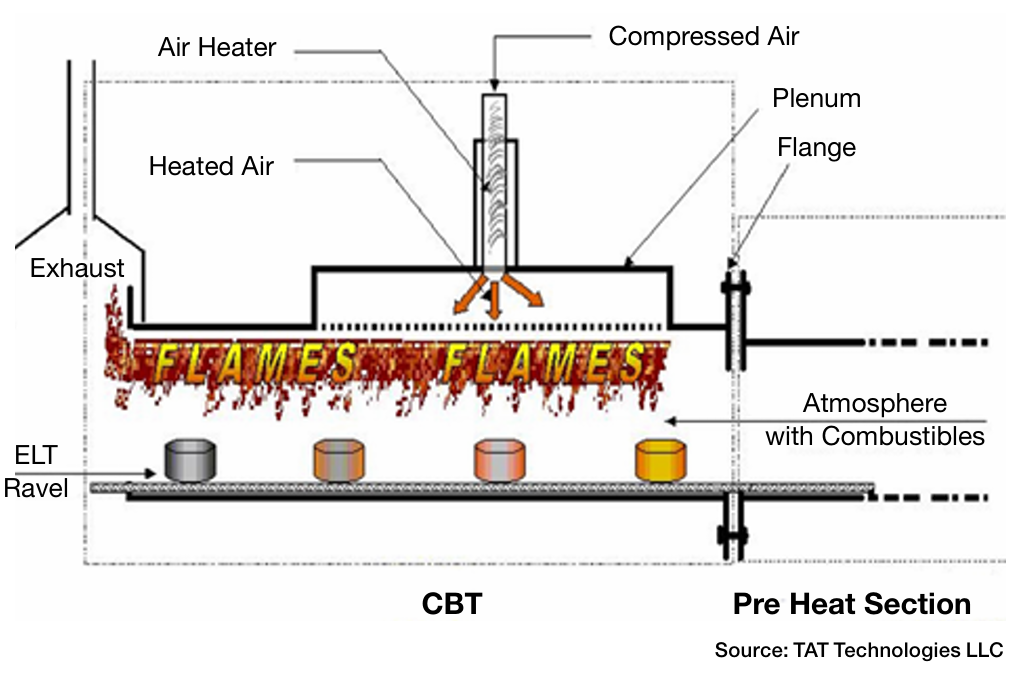

The CBT unit retrofits to the flange of the preheat muffle of the sintering furnace. In its reaction chamber, the furnace atmosphere gases enter from the heating sections carrying the various combustibles. These are circulated in the chamber in which preheated air at 1000–1600°F is introduced through vents in the roof of the chamber (Figure 1).

When the furnace atmosphere and air mix, a combustion reaction takes place with flames being produced over the incoming load of parts that are traveling on the belt towards the preheat section. Heat from theses flames helps vaporize the lubricant and any oils present at a high rate. The lubricant vapors flowing out of the parts are instantly and continuously consumed within the CBT chamber before leaving to enter the exhaust system in the front of the furnace. However, the energy released from the burning lubricants and oil vapors remains, adding to the energy from combustion within the CBT chamber. Enough total heat is generated to heat the parts and the belt to temperature above 930ºF (500ºC) before entering the preheat section. This “recovered” heat energy is essentially free as it is generated from the combustibles and lubricant and oils (e.g., H2 for oxide reduction and lubricant for ease of compaction).

Another Case Study Illustration

Energy recovery in a CBT reaction chamber from fully combusting H2 coming from the preheat section of the furnace at a flowrate of 400 CFH (11.3 m3/h) and lubricant coming with the green parts at a rate of 7.2 lbs (3.3 kg) per hour is approximately 235,000 Btu/hr (248 MJ/hr) which is equivalent to an energy savings of approximately 70 KWh of electricity.

Additional Heat Treat Applications

Many other heat treating processes benefit from CBT technology. Some examples follow next.

Annealing often utilizes continuous furnaces.

- The percentage of H2 in the atmosphere is generally much higher — in some cases 100%.

- Materials and annealing practices vary from plant to plant.

- Prior to annealing, the material often has surface oxidation and/or some type of coating (e.g., oils, dry lubricants).

- The goal is to avoid decarburization and produce an acceptable microstructure, which highly depends on the time/temperature cycle.

Brazing is another thermal process that benefits from CBT technology.

- Brazing of most automotive parts is done in either in Exothermic or Endothermic gas or N2-H2 or H2-Ar atmospheres.

- Materials being brazed are typically low carbon steels or stainless steels. In some instances, other special materials are used.

- The goal is to have clean, oxide, and soot-free joint surfaces just before the filler metal (commonly copper or nickel-based alloys) melts, flows into the gap between the parts by capillary action, and solidifies producing a homogeneous part.

Summary

- Emission control. Using combustion technology, heat treaters are able to convert potentially harmful pollutants from reaching the exhaust system.

- Increased productivity. The technology increases throughput up to 50% depending upon the model used since incoming parts are heated prior to entering the preheat section of the furnace.

- Energy savings. The power requirements in the preheat section are reduced and throughput increases up to 50% depending upon the model used.

- Improved heat transfer. Parts can be heated to a higher temperature in a shorter amount of time for faster removal of organic materials prior to subsequent reduction of metal oxides.

- Decreased unit cost. The energy consumption is lowered and overall cost of parts produced in reduced.

- Environmental benefits. Ambient temperature in the front-loading area by 10–30°F is lowered since the burn off flames are significantly smaller. Processes being run are less sensitive to air infiltration in the vicinity of the furnaces.

About the Author:

President & CEO

TAT Technologies

Source: TAT Technologies

Harb is an inquisitive learner and dynamic entrepreneur who will share his current interests in the powder metal industry, and what he anticipates for the future of the industry, especially where it bisects with heat treating.

For more information: Contact Harb at harb.nayar@tat-tech.com.