How can steel production be "green"? Where does the United States stand in steel production when compared to the rest of the world?

How can steel production be "green"? Where does the United States stand in steel production when compared to the rest of the world?

Lourenco Goncalves, chairman, president, and CEO of Cleveland-Cliffs, Inc. answers these questions and more in this article, originally published in Heat Treat Today's August 2021 Automotive print edition.

Chairman, President, CEO

Cleveland-Cliffs, Inc.

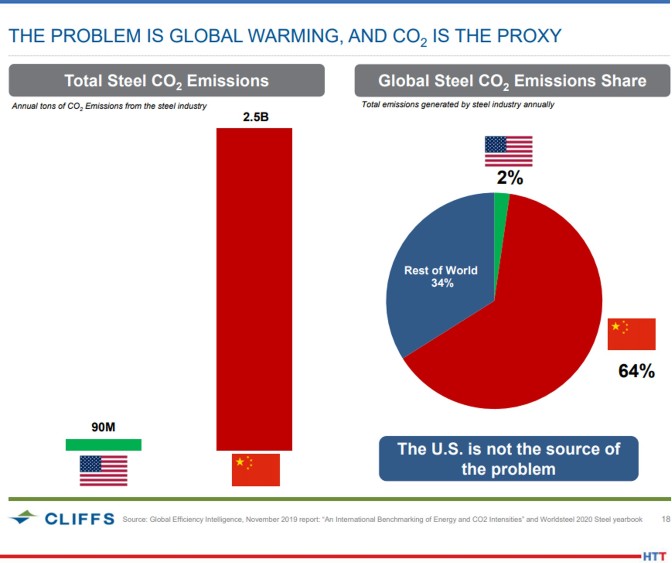

The United States is the benchmark of the world in all things steel. Amongst all major steelmaking nations, we have by far the greenest emissions profile. On average, each ton of steel produced in the United States generates 1.0 tons of CO2 emissions, compared to a ton of steel produced by China which generates 2.5 tons of CO2 emissions. The U.S. generates only 2% of all the greenhouse gas emissions from global steel production, while China contributes 64%.

The attributes that make our industry so green are the use of scrap, natural gas as both a reductant and energy source, and green iron ore pellets in blast furnaces. Because scrap cannot be used in a closed loop, natural gas and pellets allow for a healthy participation of low-carbon intensity virgin iron and steel units in a well-balanced ecosystem.

Steel’s emissions profile also makes it the lowest-carbon option compared to other materials perceived to be green, such as aluminum and carbon fiber. Adjusting for part weight, production of the equivalent volume of these competing materials generates 5 to 10 times more CO2 emissions than steel made in the United States.

This emissions profile is just one of many attributes that will support steel’s continued position as the material of choice in automotive light vehicle bodies. On top of being the greenest material and having a 100-year incumbency advantage, steel is more affordable than aluminum and is easier to weld, form, and repair or replace. Our continued innovation in advanced high strength steels (AHSS) has allowed us to produce thinner, lighter-weight, yet stronger materials, and closed the gap on the perceived density advantages that the aluminum industry has touted.

Even though we boast a low emissions profile, our work is not done. At Cleveland-Cliffs, we have made public our target to reduce greenhouse gas emissions by 25% by 2030. In our global discussion about decarbonization, the use of hydrogen (H2) as an iron-reducing agent has emerged as playing a key role in a carbon neutral future. While clean and leaving only steam (H2O) as its byproduct, large scale H2 use in steelmaking is an unproven technology that comes with enormous practical challenges, including safety and prohibitive costs. Knowing what we know today, we are probably decades away from H2 becoming part of any affordable and easily available technology.

At Cliffs, we don’t want to rely on breakthrough technologies, but rather deal with practical decarbonization options. Our efforts involve the use of the hydrogen contained in natural gas, which is actually a mix of 95% CH4 and 4% C2H6. Natural gas is used as the reducing agent at our new, state-of-the-art DRI facility in Toledo, OH, as well as a meaningful supplemental reductant in all eight of our blast furnaces. The abundance of cheap natural gas in the United States will continue to provide us ample opportunity to decarbonize.

Steel is the inevitable material of choice in a modern, greener world. As the largest flat-rolled steel producer in North America, Cleveland-Cliffs will remain on the cutting edge in shaping the future and further cementing our industry as the envy of the world.

About the Author: Lourenco Goncalves is chairman, president, and CEO of Cleveland-Cliffs, Inc.