The future is moving inexorably towards smart factories, but many smelting plants are still stuck with assembly line production in Industry 2.0 without IT support. Central elements of a modern factory of the 21st century—such as the interface to a central database server or intelligent, heat-resistant automation including sensor technology enabling all facilities to communicate with each other—are frequently not available. Although there are numerous protocols in existence for this purpose, the possibility of retrofitting these protocols standards does not exist in many older facilities. A lack of expenditure resources and the absence of vision for the future have often led to missed opportunities.

Therefore, research strategies that build on each other are always recommended in order to keep up with the times. Only in this way can a smelting plant face the numerous challenges of the future in the long term. In this article, Sven-Olaf Sauke, head of R&D at ZPF GmbH, lays out the steps taken by ZPF to invest in the future in order to meet the current requirements of the industry and create a basis for innovative products, serving as a case study for U.S.-based Heat Treat Today readers standing on the cusp of Industry 4.0 readiness with uncertainty about how climate policies will affect U.S. manufacturing.

Melting Furnace 4.0: Thinking Ahead, Developing Further, Moving On

A current challenge in Industry 4.0 is the automation of so-called predictive maintenance. In this process, the system is monitored on an ongoing basis and throughout the entire process (continuous system monitoring) to perform condition-based maintenance work. In a smart factory with a melting furnace, for example, cleaning could be carried out by a robot that knows all the parameters of a furnace and can take action in good time before a critical degree of contamination is reached. Consequently, the robot automatically prevents a later complete breakdown of the system and a standstill of the entire shop in just a few minutes.

However, as long as there is no suitable and, at the same time, safe sensor technology that can withstand extremely high temperatures, these essential parameters cannot be recorded, even though they are the basis for Industry 4.0. In order to master these complex automation tasks, the entire factory needs extensive knowledge of all important plant data—from the filling level of the furnace to the degree of contamination in the bath area. For this reason, ZPF GmbH, for example, has already laid the foundations for solutions for intelligently networked melting furnaces through various research projects in the past.

Enoptal—from refractory materials to burner technology

At this point, the ZPF project "Enoptal" serves as an example for the beginning of such a research chain. In Germany, as a result of climate policy (surrounding Directive 2009/29/EC), aluminum producers and processors with a total rated thermal input of 20 MW had to limit their CO2 emissions from 2013 and purchase new certificates if necessary. This puts pressure on companies in the aluminum industry to find timely solutions for lower CO2 emissions. Following this, more investment was made in the development of efficient burner technology to reduce energy costs and reduce the impact of greenhouse gases on the environment. The charging methods and cleaning intervals of the furnaces as well as the melting losses were examined and the influence these parameters have on the critical emission values were reviewed.

In order to determine the energy-saving potential in aluminum melting processes, researchers have developed a system for monitoring and controlling the melting process in a joint project between industry and science.

The research project "Enoptal" was funded by the German Federal Ministry for Economic Affairs and Energy, supervised by the Project Administrator Jülich, conducted together with the Technical University Bergakademie Freiberg and successfully completed in 2011. With the help of various field tests, the essential parameters of a melting and holding furnace with a melting capacity of 300 kg/h and a holding capacity of 700 kg were determined, and optimization potential was identified for the refractory material and the burner arrangement resulting in energy savings of up to 10 percent. These fundamental results formed the basis for the next major research project.

Edusal-I + II—from burner technology to sensor technology

As the next step in this research chain, the melting plant together with other plant components was at the center of the task in order to optimize the entire furnace system. The aim was to search for further energy saving potentials in melting processes with aluminum to minimize melting loss, to improve process monitoring, and to create the basis for a modern and efficient heat recovery system.

Since the field of "measurement technology" in particular has large gaps, the possibilities for a system for monitoring and control were examined in cooperation with the Federal Ministry for Economic Affairs and Energy, the Technical University Bergakademie Freiberg, and the Leibniz University of Hanover. The focus in the projects "Edusal-I and II" was mainly on the development of a measuring technique for the sensory detection of the furnace chamber.

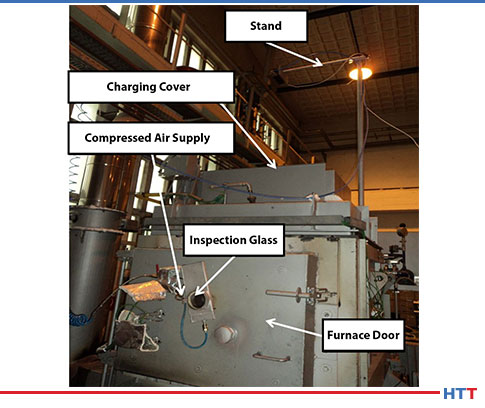

In some areas, water-cooled, optical systems are used for furnace interior monitoring—for example, after the repair of glass troughs.

Although these provide an insight into the condition of the refractory lining and other process parameters, for safety reasons they cannot be used in rough everyday operation or must not be used by operators of aluminum melting plants. If such a system is damaged and the water is unintentionally heated from 68°F (20°C) to 1652°F (900°C), the sudden change in volume of the water can lead to explosions and thus to serious damage to property and persons. For the first time, the measurement method developed with the associated software made it possible to precisely determine the amount and position of material on the melting bridge during melting operation. In this context, a dynamic burner system was developed that can be regularly aligned to the melting charge via the recorded measurement data and thus increases the efficiency of the overall system.

Although these provide an insight into the condition of the refractory lining and other process parameters, for safety reasons they cannot be used in rough everyday operation or must not be used by operators of aluminum melting plants. If such a system is damaged and the water is unintentionally heated from 68°F (20°C) to 1652°F (900°C), the sudden change in volume of the water can lead to explosions and thus to serious damage to property and persons. For the first time, the measurement method developed with the associated software made it possible to precisely determine the amount and position of material on the melting bridge during melting operation. In this context, a dynamic burner system was developed that can be regularly aligned to the melting charge via the recorded measurement data and thus increases the efficiency of the overall system.

In addition, the plant was equipped with a heat exchanger system. With the help of the exhaust gas, the required burner air is heated in the heat exchanger and directed to the burners. This heating results in a higher temperature level during the combustion process and leads to significant gas savings. The research project ended successfully in 2016 and enabled a further increase in energy efficiency of up to 15 percent in the melting plant. On this basis, assemblies were revised for series use. Today there are plants ready for trial operation which have been successfully tested. The measured values from the research project are confirmed at these plants in the rough melting operation.

AlSO 4.0—from sensor technology to automation

Thanks to the findings from the Edusal II project on sensor technology, a non-contact optical test method was developed which detects a change in the state of the aluminum block.

This is a camera system with a special evaluation logic that is able to detect non-molten aluminum on the bridge during the melting process. This new sensor technology enables an objective evaluation of the melting process in the aluminum furnace, and the user can automatically determine the current quantities of the material to be molten. In this way, characteristic values can be derived for objective evaluation of the melting performance guaranteeing continuous monitoring throughout the entire melting process. It also opens up further possibilities for automatic control processes within a smart factory.

All results of these research projects serve as a basis for the current project called AlSO 4.0 (aluminum melting furnace 4.0).

Research on control and evaluation options for automation, required for further steps in the process chain, is conducted in close cooperation with the Technical University Bergakademie Freiberg, the University of Bremen, and the Leibniz University of Hanover as well as aluminum melting furnace operator and is funded by the Federal Ministry for Economic Affairs and Energy. In this process, the areas to be examined are extended to the entire furnace system and the first prerequisites are created for integrating adjacent peripherals and achieving the desired increase in efficiency. The frequently described scarcity of resources will be the driver for further technical development, which cannot be achieved without research work. Long-term and systematic research pays off.