A major provider of innovative heat processing solutions recently developed an augmented reality (AR) system in conjunction with a global technological corporation to adapt its holographic computer systems to metallurgical applications in the manufacturing environment.

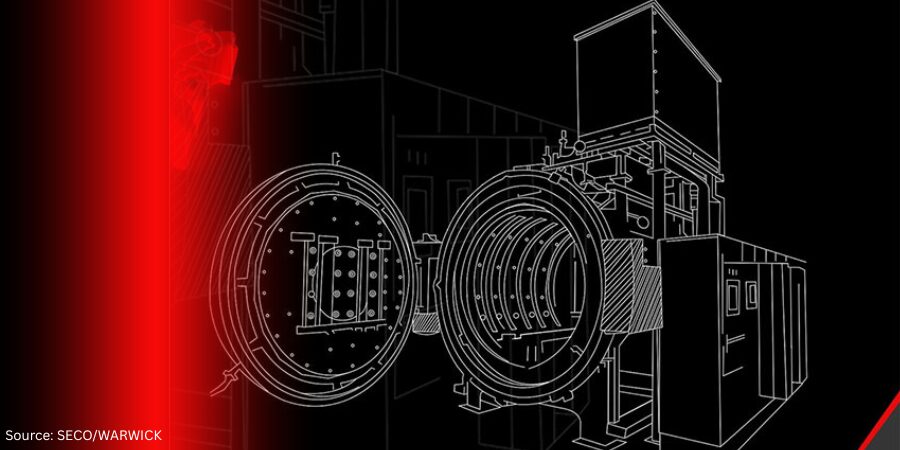

SECO/WARWICK introduced SECO/LENS, an adaption of Microsoft’s HoloLens, to bring the advances in virtual reality to manufacturing enabling users to view equipment, systems, and processes in 3D; this is the first use of this technology by heat treatment industry.

SECO/WARWICK introduced SECO/LENS, an adaption of Microsoft’s HoloLens, to bring the advances in virtual reality to manufacturing enabling users to view equipment, systems, and processes in 3D; this is the first use of this technology by heat treatment industry.

SECO/LENS can superimpose a 3D model of a specific piece of heat treating equipment or an entire technological line, providing the most optimal layout of the production line on the plant floor for the line’s monitoring, diagnostics, maintenance, remote repair, and planning. SECO/LENS is intended to create an accurate visualization of the system, permitting staff training on the operation of the equipment without the need for expensive and time-consuming travel.

“SECO/LENS is a new era of working with SECO/WARWICK devices—it’s the era of interaction,” said Slawomir Wachowski, Automation Department Director for SECO/WARWICK. “Introduction of virtual technologies to the production process, training, and operation of our devices are significant benefits, more intuitive device operation, increased mobility, increased efficiency and reduced response times to service requests.”