Welcome to another episode of Heat Treat Radio, a periodic podcast where Heat Treat Radio host, Doug Glenn, discusses cutting-edge topics with industry-leading personalities. Below, you can either listen to the podcast by clicking on the audio play button, or you can read an edited version of the transcript. To see a complete list of other Heat Treat Radio episodes, click here.

Welcome to another episode of Heat Treat Radio, a periodic podcast where Heat Treat Radio host, Doug Glenn, discusses cutting-edge topics with industry-leading personalities. Below, you can either listen to the podcast by clicking on the audio play button, or you can read an edited version of the transcript. To see a complete list of other Heat Treat Radio episodes, click here.

Audio: John Vanas on SX Oil Lifters

In this conversation, Heat Treat Radio host, Doug Glenn, tours Euclid Heat Treating Company with owner John Vanas and discusses a nano-technology parts washing solution.

Click the play button below to listen.

Transcript: John Vanas on SX Oil Lifters

The following transcript has been edited for your reading enjoyment.

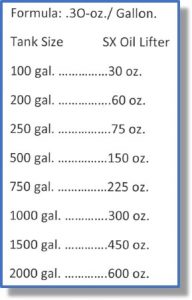

If you’re a manufacturer and you use parts washers to remove oil residue from metal parts as part of your manufacturing process, or if you’re a commercial heat treater who washes parts, today’s Heat Treat Radio episode should be especially interesting to you. Why? If you thought there was nothing new in the parts washing arena, you’ll be shocked at what you’ll learn today. Let me whet your appetite. What if I told you there is a parts washing additive out there where you only had to add .3 ounces — that’s right, .3 ounces — to every gallon of wash water? And what if I told you that you could run that solution for 3 to 4 months without adding any chemicals? And what would you say if I told you that the oil skimmed off of your wash bath would have a lower water content than anything that you’re currently using? And what would you say if I told you your maintenance team would never have to check the concentrations of your wash water again? Not enough? Okay, let me give you one more. What if I told you that when you were done with the bath, you could just dump it down the drain?

Sounds too good to be true, right? Well, buckle up, because Heat Treat Today is going to take you where no heat treat washing system has ever gone before.

For today’s episode of Heat Treat Radio, your host, that’s me, Doug Glenn (I’m also the publisher of Heat Treat Today, which you can find on the web at www.heattreattoday.com), took a road trip to Euclid, Ohio, to visit with a current user of the wonder wash additive I just described to you. It was a rainy day, so any raindrop noises you hear are, in fact, raindrops.

John Vanas (JV): This is our rotary retort building.

Doug Glenn (DG): Ok, great.

JV: And this is Euclid Heat Treating Company. I am John Vanas. It was established in 1946 by my father. So we have been around for 72 years.

JV: And this is Euclid Heat Treating Company. I am John Vanas. It was established in 1946 by my father. So we have been around for 72 years.

DG: 72?

JV: 72 years. I have been here 46 years.

DG: And it is a family business, right?

JV: Yes, a family business. I have got three kids working here and we are probably the most diverse commercial heat treater in this area. We do a lot of different things: induction, rotary retort, batch, pit, nitriding, ferritic nitrocarburizing, and intensive quenching. We have got quite a bit of different processes that we do.

John and I are on a walking tour of his six-building commercial heat treat complex just northeast of Cleveland, Ohio.  As he mentioned, Euclid Heat Treat Company is no fly-by-night establishment. John’s dad started the business and has passed it down to John who is well on his way to passing it on to his kids. Before we jump into the specifics of the “wonder wash” additive, which by the way, is not the name of the product — it is called SX Oil Lifter — but before we jump into the specifics of that additive, here is a bit more about the family business.

As he mentioned, Euclid Heat Treat Company is no fly-by-night establishment. John’s dad started the business and has passed it down to John who is well on his way to passing it on to his kids. Before we jump into the specifics of the “wonder wash” additive, which by the way, is not the name of the product — it is called SX Oil Lifter — but before we jump into the specifics of that additive, here is a bit more about the family business.

DG: So you got it from your dad?

JV: Yes.

DG: Roughly, when?

JV: Actually he passed in 1991. I have been running it since 1974. We had a general manager who ran the plant and he passed away, so they threw it to me. I was here for two years and my dad said, “It’s your baby. I am going to Florida.” So, that’s alright.

DG: And you have three kids?

JV: Three kids.

DG: Which are Deidre, John ….

JV: ….. and Claudine. They work here. John runs production, Deidre is going to be the General Manager, pretty much, and Claudine does the finance work. And I just try to keep everybody in line.

The Plant Floor: Where the Magic Happens

John and I were standing at the entrance of his rotary retort building, as I mentioned, one of the six buildings, located just off of 222nd Street in Euclid. As we were working our way to washer end of one of his rotary retort furnace lines, John explained the markets he serves with these furnaces.

JV: Two rotaries we’ve got an AGF 139 and an 1814, so this is a large retort that quenches into polymer and this one quenches into oil and goes right through the wash and out the other end to the finished product. Not too many people do rotary work anymore. There are a few of us around, but the beauty of this is the parts tumble and they get even case all over where with a belt furnace they mask each other by laying on each other, so it’s a good technology. Kind of a niche market for us.

DG: So it’s primarily fasteners?

JV: Fasteners, little stampings, just a little bit of everything. You can see here these are actually plugs for automobile and truck oil pans. We do a ton of these things. There’s a little stamping here that we’re running. You name it, if you have to have even case hardness we can do it in these two furnaces.

We then moved our way to the discharge shoot at the back end of the first rotary retort furnace where parts fell into an oil quench and then on into a spray washer. John wanted me to see that the oil being pulled out of the washing solution was almost 100% pure oil; very little, if any water. Here’s how John tells it:

JV: So we load through the retort into the oil quench then into a wash. This is a spray washer. Then we’ve got one of these hula hoop type tooth skimmers that skim the oil off into this drum. If you can see that; that’s almost pure oil. This is the XS Oil Lifter in here. But that’s almost pure oil. There is no water in there.

We spent a few more minutes discussing John’s rotary retort lines and the washers associated with it, including a disc skimmer and another bucket of, as John describes it, “pure oil — there’s no water in there.” The point being, there is a cost savings when you send this oil out to be processed since there is very little water in the oil.

We next walked by Euclid’s intensive quench system which is essentially an IQ furnace sitting on top of an 11,000-gallon quench tank. Euclid’s intensive quench capabilities is another unique offering for the company.

From Skepticism to New Product Line

After leaving the intensive quench and rotary retort building, we got into the meat of our conversation as we walked in the rain between buildings. The wonder-wash additive which I mentioned, called SX Oil Lifter, I asked John to tell me a bit more about that product.

DG: So John, one of the reasons I came over is we want to talk about this SX Oil Lifter.

JV: Yes, this is a new product that was introduced to me, and I tried it just on a whim because I didn’t think it was going to work in a small wash that we’re going to see over here in one of our other buildings. And it worked so well, I’ve got it now in six washers.

DG: Maybe before we go back into the noise of the building, it was introduced to you by whom?

JV: Actually by a friend of Bill Lohn, he’s my partner. So we decided to give it a try. I put it in a washer and it worked so well that we put it in other washers. It lasts 3 to 4 months and then you change it. You never have to add anything to it, which is the beauty of it. And it just does a great job. So after 3 to 4 months, usually you get oil in the washer and up on the walls of the washer. It just gets kind of scummy. We’ve had some people use it and not change it for 6 months. It just depends on what you’re washing and how often you’re washing.

DG: Now, Bill found out about from who?

JV: He found out about it from a friend of his that was using it for another type of washing and they had initially had developed through industrial but no one was using it for that, so we negotiated with the company to get the license to do it by industrial type of washing. So now we’re the partners and we’re really the company for the industrial side. We’re trying to introduce it to the heat treating industry because once you try it, you’re going to like it.

Nano-Invasive Technology

DG: So just to be clear on it, it’s not a washer, it’s a chemical, but it’s not a chemical-chemical. It’s very biodegradable….

JV: It’s biodegradable. You can probably drink it. When you’re done with it, you can just put it down the drain. If you have oil that you haven’t skimmed off, you can let it settle out and drain it off that way, but most people just dump it right down the drain. There is nothing biologically harmful about it. There is nothing to harm the sewer. Our people test our sewers once a month here and they have found nothing. So that’s how we dispose of it, we just dump it down the drain.

DG: You were also mentioning about the quantity that you have to put in.

JV: Yes, it’s 3/10ths of a percent per gallon.

DG: So for a typical quench tank, what do you put in?

JV: Well this quench tank here has 750 gallons and I think we’re putting 80 ounces in there.

DG: And that 80 ounces will last you for 3 to 4 months, and maybe longer.

JV: Yes, then when you’re done, you dump it down the drain, clean it out and redo it.

DG: Ok, one other thing I wanted to ask. You said they call it “nano-invasive technology”?

JV: Yes, nano-invasive technology. What we found out is it does not actually dissolve in the water like your Tide or some other detergent or Simple Green. So, it’s in there and it’s lifting the oil, but it’s not dissolved in there, so when you’re dumping the fluid, you’re not dumping a dissolved chemical. And the fact that it is not dissolved, you don’t pull off that chemical you don’t have to add. You add water through your float valve, but you won’t add more product. The water evaporates, the product does not.

Seeing the Wonder Wash in Action

From there we went into the big batch building where three Super Allcases (a product of Surface Combustion) were located along with an older Lindberg IQ and a number of temper furnaces.

John showed me a batch wash that had just had the fluid changed the weekend prior, after 3 to 4 months of use. According to John, they probably could have gone longer, but that is the interval his maintenance team established to clean and change out the washing fluid. All the maintenance team did was wash down the inside of the washer and remove all the oil residue, skim off the oil from the top of the bath, and then dump the wash fluid down the drain. That’s it.

From the big batch building, we moved on to induction building.

JV: We have different stations and different power sources. We probably have about a dozen power sources and probably 40 different stations for doing different things. We’ve got a bolt machine there that he’s working on. We have a rotating machine there for different gears. We do a little bit of everything in here. We’ve got it crammed into the building pretty good. We just had this mezzanine put in and put the power sources up on top.

John’s father started the induction division. It was one of his special interests. John indicated that Euclid does a lot of work with local induction genius, as John describes him, Bill Stuehr of Induction Tooling out of North Royalton, Ohio, not far from Euclid.

The last building we entered was the vacuum and pit building.

JV: Here we have our vacuum equipment, our pit furnace, and our little batch furnace.

This building had about a dozen different vacuum and pit furnaces. After hitting this last building, we went back to talking a bit more about SX Oil Lifter and especially on the cost savings.

Pouring Savings into the Tank Instead of Down the Drain

DG: I assume there are cost savings here, right?

JV: Yes, it’s going to be about a third of what most people are using, from what we can determine. At least from what we used to use. We used to use a product from one of our oil suppliers and it would kinda make a funny-looking emulsion on the surface. And when we skimmed it off, we’d have to put it in the tank, let it settle out, drain it off until we got down to the oil and take the oil out. But we found out that we were getting a pretty good percentage of water in the oil when we sent it to the recycler. So he would charge us for getting the water out.

DG: So when you changed over the oil lifter, you didn’t have any problem with your current equipment that you used to separate the oil out I assume, right? There was no adverse effect?

JV: No, it was the same skimmer we always used, but it was just much more efficient.

DG: And you’re getting much better purity?

JV: Yes, we’re pretty much getting all oil in the tanks from the skimmers instead of an all water mixture.

When we walked back outside and headed back to John’s office, I asked him to repeat the cost savings information.

JV: It looks like from what we’ve seen from what our products we used to use, it’s going to be about a third.

DG: So you’re saving two-thirds?

JV: Yes. Plus, again, the beauty is, you don’t have to add all the time. You don’t have to have somebody coming in titrating. You can’t titrate this stuff. You can’t figure out what the percentage is because it’s such a small percentage, it doesn’t show up. We’ve tried several different methods to try to determine if we’ve got the right mix still in the tank, but we’ve come to the conclusion that you can’t. So, you put it in, you use it for 4 months or 3 months. When it starts to get to the point where perhaps it’s not cleaning the oil off well enough, you dump it and refill it.

DG: And you judge that not by taking any chemical composition of the solution, you just watch the parts, and if you’re seeing oil residue, it’s time to change.

JV: Exactly. And that kinda flies in the face of someone with technical knowledge, but that’s the way it works. You can tell if you’re washing off quench oil, if you start getting a smokey temper load, obviously you’ve got too much oil in there.

Once we got back to John’s office, I pressed him even more on the cost savings.

JV: We know the product we were using before was pretty expensive and I’ve talked to people who have tried and it and they said we’re putting a 55-gallon drum a month into our washer of the product we’re using now. And I said, well you won’t be doing that with SX Oil and I know that stuff is pretty expensive.

We further quantified the savings by talking about the money saved on oil processing because of less or no water in the oil being processed, plus the time savings of not having to test concentration levels of the wash. John had more to say about the time savings.

JV: Just talking to some other people who have tried the product, they said we’re going to save a lot of money because we have a guy who has to titrate it, has to add to it, and we don’t have to do that anymore.

DG: And they’re paying for that, I assume. They’re paying for that service or they’re paying one of their employees.

JV: Usually one of their employees. But it’s time-consuming and it’s a lab situation and titration. And with this, you don’t have to do anything.

I asked him if he had ever run into any problems with the product. He said that one customer called complaining the parts washed in the product were rusting faster than normal. After John and his fellow user discussed it for a while, they concluded that the product was doing such a good job of removing the oil from the surface, that it was more prone to rusting. What was the solution? John is working on adding a rust preventative to the product to help minimize the issue.

If it sounds too good to be true, it’s not. Here’s a brand new product. In fact, a brand new nanotechnology product, that

- requires only .3 ounces per gallon of water,

- lasts for 3-4 months minimum depending on your workload and oiliness of your products,

- results in an almost pure oil skimming which minimizes oil reprocessing fees,

- frees up your maintenance team to do other things besides worry about the washer,

- and best of all, when you’re done, dump it down the drain.

If you’d like more information about SX Oil Lifter, please visit our website www.heattreattoday.com and search for SX Oil Lifter. We’ll have a full article about the product on the website along with a link to the product’s website. You can also email me directly if you’d like to get in touch with John Vanas at Euclid Heat Treat in Euclid, Ohio. My email address is doug@heattreattoday.com.

If you’d like more Heat Treat Radio, including our series on metallurgical poster children where we interview young, new metallurgical minds, please visit our website www.heattreattoday.com and click on Heat Treat Radio. Visit the website frequently. We post at least one heat treat news or technology item every weekday. Our content is targeted at manufacturers with in-house heat treat departments, especially in the aerospace, automotive, medical and energy sectors. Again, visit us at www.heattreattoday.com.

And finally, if you have a specific topic you’d like to see covered on Heat Treat Radio, please contact me directly at doug@heattreattoday.com.

Heat Treat Radio podcasts are the sole property of Heat Treat Today and cannot be reproduced without permission and appropriate attribution. This episode of Heat Treat Radio was produced and mixed by Jonathan Condon, Butler, Pennsylvania.

My name is Doug Glenn. Thanks for joining us.

To receive a copy of Euclid’s Safety Data Worksheet for SX Oil Lifter, contact Doug Glenn at doug@heattreattoday.com.

To find other Heat Treat Radio episodes, go to www.heattreattoday.com/radio and look in the list of Heat Treat Radio episodes listed.