A distributor of data loggers, paperless recorders and data acquisition equipment recently supplied a surface treatment company with runtime data collection to continually monitor its salt bath production line.

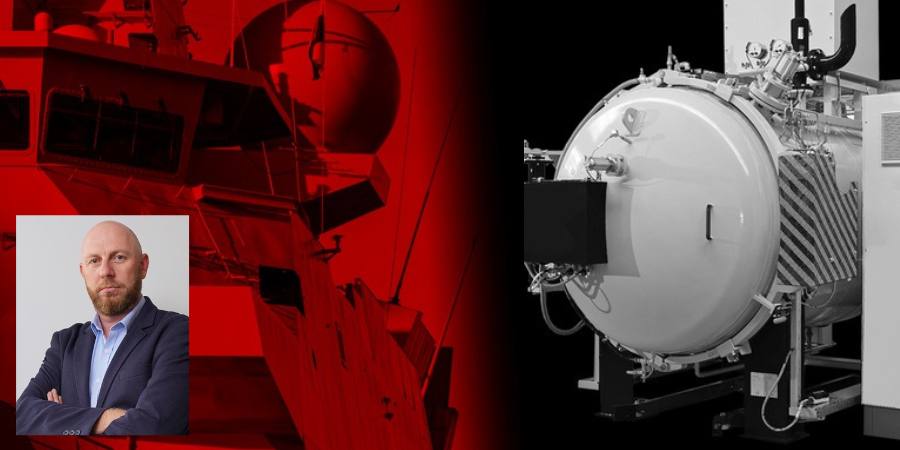

CAS DataLoggers provided the industrial data logging solution to Northeast Coating Technologies (NCT) in Kennebunk, Maine. NCT is a surface treatment company specializing in Salt Bath Nitriding Melonite® Quench-Polish-Quench (QPQ), among other processes, to produce high-durability metal components including piston rods, axles and more. NCT is using CAS’s dataTaker DT80 Intelligent Data Logger to continually monitor its production Melonite® line, specifically the salt bath area, recording tank temperature from multiple thermocouples and using these readings to trend the run data.

The Melonite® QPQ process forms a nitrocarburized layer around components comprised of an outer compound layer (iron, nitrogen, carbon and oxygen compounds) and a diffusion layer underneath. Initially, the process preheats components to raise their surface temperature before they’re placed in a tank containing liquid Melonite® salt (MEL 1/TF 1 bath) to start the nitrocarburizing process. Alkali cyanate is the active constituent in the salt bath, and this step requires the temperature in the range of 896°F – 1166°F with a target temperature of 1076°F. The components react with the salt and start to diffuse nitrogen and carbon into the substrate.

After a preset period of 1-2 hours, the components have the proper compound layer thickness and case depth. After immersion in the salt bath, the components are placed in a cooling bath (AB 1 bath) maintained at 700°F – 800°F for oxidative treatment which forms a magnetite layer on the components to improve corrosion resistance.

Tank temperature is the parameter NCT needed to monitor and trend for each of its 3 Melonite® salt tanks and the AB 1 oxidizing bath tank. With this in mind, CAS DataLoggers provided the facility with a Series 3 dataTaker universal data logger to automate their data collection.

“The dataTaker’s software is internal so everything this application needs is there in the dataTaker unit itself,” said CAS DataLoggers Applications Specialist Bill Hoon. “Now they have the memory, the data trending capability, and the alarming feature. That’s why the DT80’s our workhorse.”