Heat Treat Today publishes twelve print magazines a year and included in each is a letter from the editor, Bethany Leone. In this installment, which first appeared in the January 2025 Technologies To Watch print edition, Bethany reports on the changing landscape of the industry and the resulting challenges, according to a poll on LinkedIn. Respondents shared their views on uniformity and temperature control, residual stresses, managing downtime, and more, and our editor gives her summary of the feedback.

Feel free to contact Bethany at bethany@heattreattoday.com if you have a question or comment.

January 2025 Magazine

Now granted, heat treating isn’t in a romantic relationship, but this 2025, there are many relationships that have vied for the industry’s attention over the past decade plus. 2025 seems to be the year to scratch the itch that heat treaters have: Is it time to try something new?

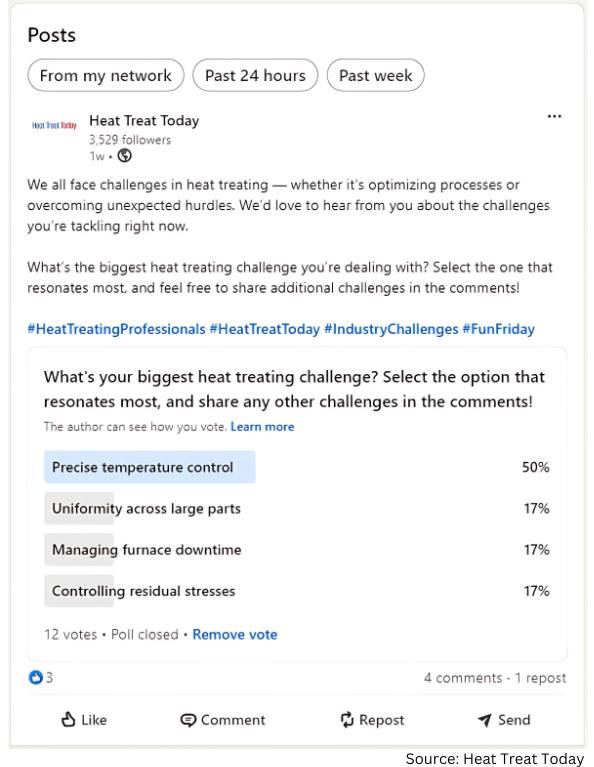

Recently, Heat Treat Today released a poll on LinkedIn. We asked what the number one challenge that heat treat experts faced in the North American manufacturing industry. There were several big-ticket items that we offered: Precise temperature control, uniformity across large parts, managing furnace downtime and controlling residual stresses. Unsurprisingly, temperature control was voted as the top challenge of the four choices, though it was surprising that few respondents piped in on the topic of residual stresses.

Yet perhaps the most important engagement came from a commenter who addressed using legacy materials in changing industry requirements. How closely are we thinking about the future that materials — use of legacy materials as well as different legacy materials — have on our work in heat treatment? (Ok, your work. We all know that I’m leaving the discovery and application to you!)

As the commenter noted, the choices in the poll are all critical characteristics, and therefore factors heat treatment practitioners should already be concerned with. If you are looking at your heat treat operation’s relationship with a variety of processes and technologies and think that the relationship is ideal as can be, great.

But if you are in the “seven-year itch” camp — that is, there is some relationship with a process or technology that is on the rocks — this new annual magazine we are releasing each January highlights the heat treat technologies to watch for in 2025. It’s time to reevaluate the relationship your heat treat operations have with current technologies.

Technological Relationships Under Consideration

The heat treat industry is navigating a rapidly evolving landscape shaped by new materials and technologies. Additive manufacturing (AM), or 3D printing, introduces unique material requirements that challenge traditional heat treating. Complex geometries and the use of non standard alloys in AM demand processes tailored for uniformity and precision at an unprecedented level. These disruptions, coupled with constant innovations by researchers in materials science, are prompting a reevaluation of whether conventional heat treating methods are needed as is, or even at all. Check out the AM quiz on page 24 to get up-to-speed on some of these developments.

Meanwhile, robotics and AI are revolutionizing how operations are managed. AI-powered predictive maintenance is becoming indispensable, helping to minimize furnace downtime by identifying potential failures before they occur. Machine learning enhances furnace control systems by refining temperature cycles and gas flow in real time, ensuring consistency and efficiency. How are these systems working for heat treaters? Read the case study article on page 10.

Digitalization technologies, such as smart sensors and IoT-enabled systems, are making it easier than ever to monitor and analyze heat treating operations. These tools, combined with advanced software, empower operators to make data driven decisions and reduce energy consumption. Several articles in last month’s magazine release focused heavily on these technologies, but the conversation persists in the commentaries found on pages 17 and 27.

The question for 2025 is clear: Are heat treaters ready to adopt these innovations and adjust their processes to align with the needs of tomorrow’s manufacturing? Have your operations found the perfect relationship with these new technologies? Tell me what you’re finding to be most difficult to address in 2025 so we can examine that relationship in future editions.

Managing Editor

Heat Treat Today

Contact Bethany at bethany@heattreattoday.com.

Find Heat Treating Products And Services When You Search On Heat Treat Buyers Guide.Com