Source: Nitrex

Beymetal Alüminyum, a manufacturer in the aluminum extrusion industry and based in Türkiye, is overcoming limitations with an outdated gas nitriding furnace with the installation of a batch-type nitriding/nitrocarburizing furnace.

This Nitrex furnace installation will increase their in-house nitriding capabilities. With a much larger furnace size and advanced technological capabilities, the company has pushed the boundaries in die performance to meet increasing production demand.

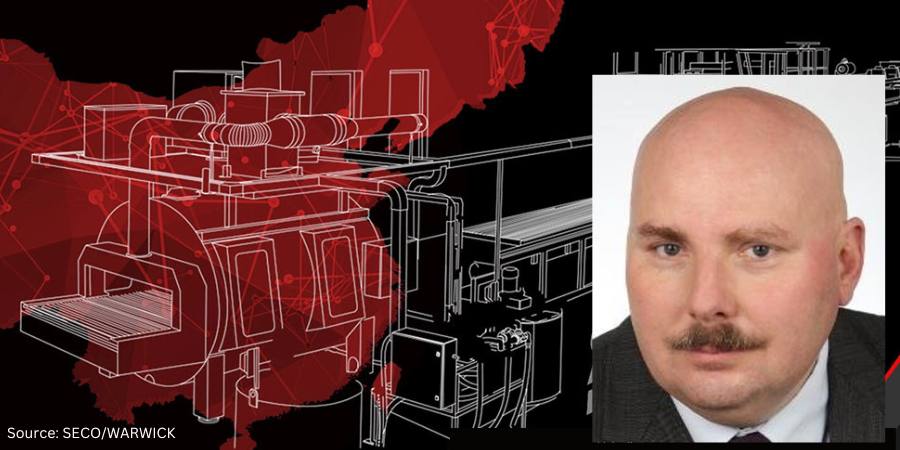

Technical Sales Manager

NITREX Poland

Source: LinkedIn.com

The NX-1015 furnace model, with a 2,000 kg (4,400 lb.) capacity, is equipped with Nitreg® controlled nitriding and Nitreg®-C controlled nitrocarburizing, tailored for treating extrusion dies for aluminum profiles used in architectural applications. These technologies ensure precise control over uniform case depths and nitride/nitrocarburizing layer formation. This enhances the mechanical properties of the extrusion dies, resulting in a long service life and increased output per die, lowering the overall tooling costs for Beymetal. Additionally, the new installation contributes to more efficient use of production media and reduces electricity consumption.

For Marcin Stoklosa, manager of Technical Sales for the EMEA region at Nitrex, commented, “The need for extrusion companies to enhance tooling performance while prioritizing sustainability represents the future of the aluminum industry. Beymetal’s adoption of Nitrex nitriding and nitrocarburizing technologies serves as an example of this necessity. This transition harmonizes production with global sustainability initiatives for a more environmentally friendly future.”

The original press release can be accessed here.