The horizontal quench furnace has a maximum temperature rating of 1,250°F, a work chamber of 6’W x 2’H x 4’L. It is electrically heated with 144kW of heat input and SCR power control. The recirculation system utilizes a 15,000 CFM blower with combination air flow design to maximize temperature uniformity. This horizontal quench system features guaranteed temperature uniformity (+/-5°F at 870° F and 1,000° F) and meets the requirements of AMS 2750E Class 1.

The quench tank is a 12 gauge 304 stainless steel construction, and utilizes a pneumatically actuated quench elevator to lower and raise the load into the tank. The system provides a seven (7) second maximum quench time. The quench tank has a 1,600 gallon capacity and agitation pump rated for 250 gallons per minute. The tank is designed for a 20°F maximum water temperature rise (when load is quenched).

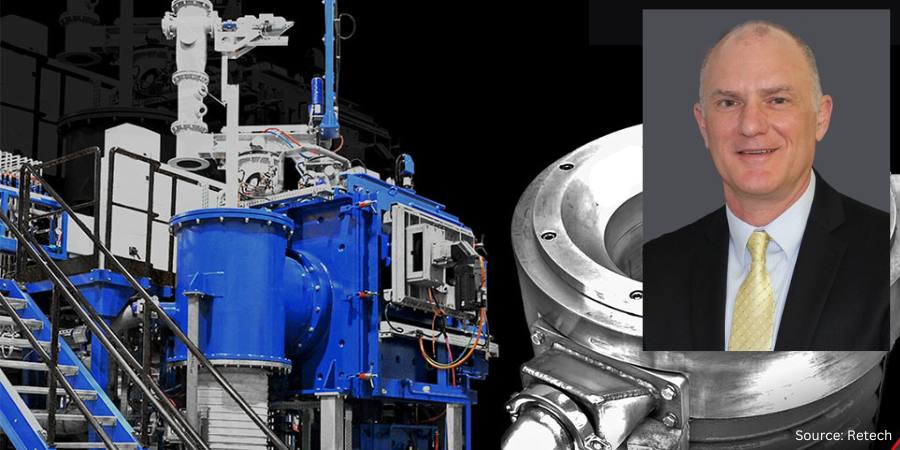

“A Horizontal Quench System is a cost effective option for our customers that perform solution heat treating processes. It offers many of the typical drop bottom capabilities and features with a smaller footprint, saving on the customer’s valuable floor space.” Jim Lucas, Senior Sales Engineer

Unique features of this horizontal quench furnace include:

- Seven (7) second maximum quench time

- Non-heated stainless steel rinse tank with agitation

- Powered load/unload table

- Meets AMS 2750E Class 1 specifications

- Pusher/extractor (load pusher) system for automatic loading and quenching

- Oven relay and sequence control performed by an Allen Bradley PLC

- Operator interface control (for oven/quench/pusher) with 10” color touch screen HMI