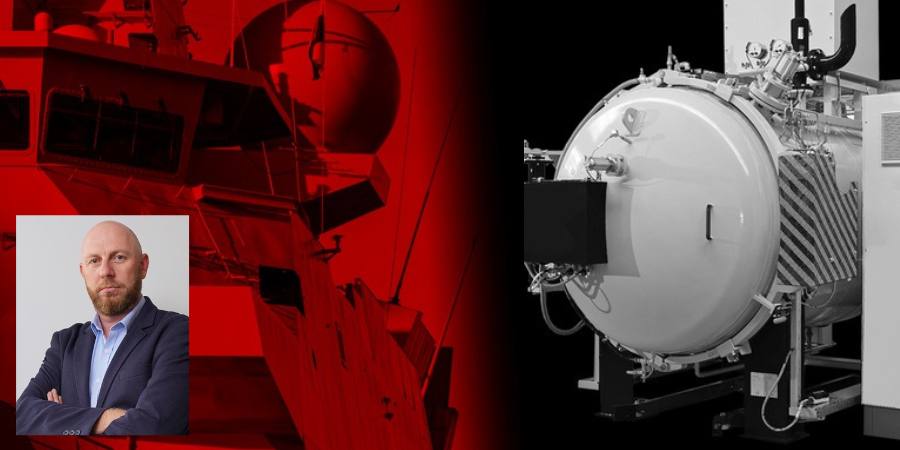

A leading manufacturer and supplier of cupronickel (CuNi 90/10 & CuNi 70/30) pipes, fittings, and flanges based in Shanghai, China, recently updated its annealing furnace to improve physical properties of copper nickel pipes, flanges, and fittings.

Through this upgrade, Shanghai Shihang Copper Nickel Pipe Fitting Co., Ltd., aims to improve performance and surface finish of all Shihang seamless copper nickel pipes (less than 419mm OD).

“Our focus is to manufacture seam welded and seamless copper nickel pipes that meet the dynamic needs in all applications,” said Kurt Yang, Shihang Export Manager. “Therefore, as a company, we must upgrade our manufacturing plant, to increase our capacity and capability for the growing demand of CuNi 90/10 and CuNi 70/30 pipe systems.”

With the new annealing furnace, Shihang strictly controls most physical and chemical properties of copper-nickel pipes. The furnace accurately controls the annealing temperature, thereby hardening and removing all internal stresses in Shihang copper nickel pipes. By upgrading the annealing furnace, Shihang will attain a better surface finish of copper-nickel pipes, thereby increasing the aesthetic value; even during the annealing process, the new furnace will not alter the chemical composition of the copper-nickel pipes.