Changes are inevitable, but the world today is changing so rapidly that it’s constantly keeping us on our toes. Do two men from different parts of the world, both with significant experience within the heat treating community, have vastly different perspectives on the happenings in the heat treat industry?

Changes are inevitable, but the world today is changing so rapidly that it’s constantly keeping us on our toes. Do two men from different parts of the world, both with significant experience within the heat treating community, have vastly different perspectives on the happenings in the heat treat industry?

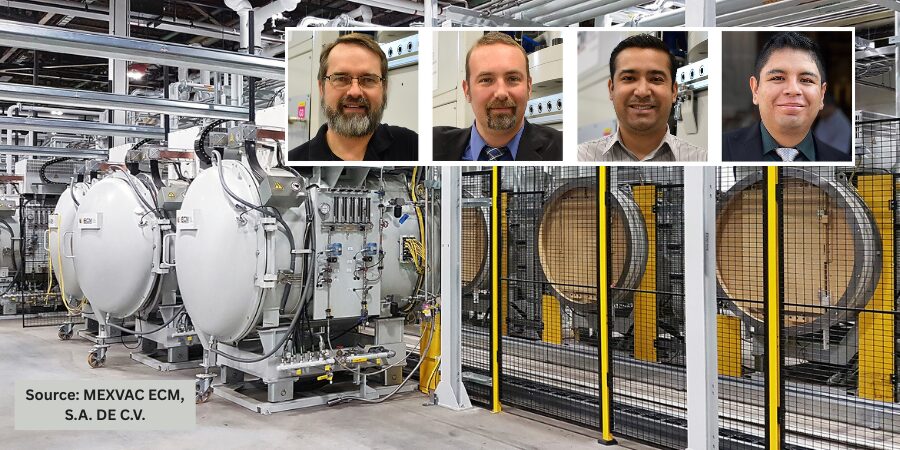

We want to find out, so we asked a question that focuses on the world of heat treating to Thomas Schneidewind, the editor-in-chief of heat processing magazine, and Doug Glenn, the publisher and founder of Heat Treat Today. The question: Is green hydrogen a game changer in the heat treat industry?

Thomas’s expertise lies in the European market while Doug’s resides in the North American market. We will feature their responses in each print magazine. Will their views align? Time will tell. Enjoy this third installment of an ongoing column. This column was first published in Heat Treat Today’s August 2022 Automotive print edition.

Is Green Hydrogen a Game Changer in the

Heat Treat Industry?

Thomas Schneidewind, Editor-in-Chief, heat processing magazine

Green hydrogen is the oil of tomorrow

Editor-in-Chief

heat processing Magazine

Last year, as moderator of our “Hydrogen in Practice” webinar, I had conversations with representatives of various industries about hydrogen. We always came to the same conclusion: technically, everything is already feasible today, only hydrogen is missing. Whether combustion processes, infrastructure or even the fuel cell, ultimately all the processes and technical challenges are not only known, but already solved. After all, hydrogen is an industrial gas that has long been used in many processes and is sometimes simply produced as a waste product. When hydrogen comes into contact with atmospheric oxygen and the necessary ignition energy is supplied, both burn together to form water. In the process, up to 90% of the energy that previously had to be applied to split the water is released again. During its combustion, apart from water in the form of water vapor, only a very small amount of nitrogen oxide is formed through reaction with atmospheric nitrogen. No hydrocarbons, no sulfur oxides, no carbon monoxide and, above all, no carbon dioxide are produced. This is why hydrogen is the great hope of the energy industry and a key building block in the decarbonization of the industry.

In 2050, hydrogen will be the most important energy carrier for energy-intensive industry alongside electricity produced by renewable energies. We need hydrogen for the direct reduction of iron ore (DRI) in the steel industry as well as for burners in the heat treatment industry. Many metallurgical processes require the use of gas-fired burners. Electric heating in heat treatment is not an alternative in many cases. That is why the “all electric” concept pursued by some politicians has long since been abandoned, after many engineers from the industry have spoken out. That is why hydrogen will be the green gas of heat treaters in the next decades. But it’s still a long way to get there.

Alongside renewable electricity, green gases such as hydrogen are seen as a central element of the German and European energy transition. The German government and the European Union have long recognized this and are funding government projects worth billions of euros, as in the Important Projects of Common European Interest (IPCEI Hydrogen). Nevertheless, a large-scale hydrogen economy is still a long time coming.

The first step to be able to use hydrogen as an energy carrier on a broad scale in the future is to build up an infrastructure, both here and in the future exporting countries. At least in Germany, the starting position is very good; with the existing gas infrastructure, there is already the foundation for a successful hydrogen future. Nevertheless, investments are necessary here as well, but above all the necessary development of the international infrastructure is capital-intensive. For investors, however, it will only become attractive when development and market opportunities arise in the interim to long term.

The development is driven by climate protection legislation. On June 24, 2021, the German Bundestag (German federal parliament) passed a new Federal Climate Protection Act. The amended law raises Germany’s greenhouse gas reduction target for 2030 to minus 65% compared with 1990. Previously, a reduction target of minus 55% applied. By 2040, greenhouse gases must be reduced by 88%, and greenhouse gas neutrality must be achieved on a binding basis by 2045. That is why many companies are investing in the green market.

Electrolyzer manufacturers aren’t able to handle the fast-growing demand. Metallurgical plant manufacturers are also far from being able to process all the requests from customers in the steel industry in a timely manner. The problem is not only the lack of hydrogen, but also the limited resources of plant manufacturers. The steel industry and heat treaters cannot be transformed and decarbonized within a short time. Even though these problems are focused on today, the structural change will take time. It’s the classic ketchup effect that everyone knows: You hit the bottle, and nothing comes out the front – but eventually everything comes out at once. Everyone knows that hydrogen is coming, but no one can say exactly when and in what quantity. Only some politicians claim to know this. In my opinion it’s up to the industry to manage this. I’m convinced that hydrogen will be the oil of tomorrow. We will see in 2045 if I was wrong.

Doug Glenn, Publisher, Heat Treat Today

No. Nor do I see it being a significant player within the next decade. By significant, I mean more than 5% of all heat treat combustion being fueled by green (generated by renewable or low-carbon sources) OR gray (steam/methane reformed)

hydrogen.

Publisher and Founder

Heat Treat Today

That’s the short answer.

But it’s the “why” behind the answer that is important. And the “why” is predominantly economic. As some experts I’ve been talking to say, “The price of hydrogen at the burner nozzle.” The nozzle price is impacted by three significant factors:

- The cost to produce the hydrogen

- The cost to deliver the hydrogen

- The cost to store and/or use the hydrogen

None of these costs are anywhere near competitive given current technology or infrastructure, and it is going to take well over 10 years to get those technologies and infrastructures in place. And that assumes that there is adequate economic incentive – not political or environmental incentives, but economic incentives – in place TODAY. These economic incentives don’t exist today, especially here in North America. Some have argued that geopolitical disruptions have made hydrogen a bit more appealing. Possibly. Nonetheless, it is drastically more profitable to fire with natural gas than hydrogen, and there are no market-driven economic incentives to push us toward hydrogen at this point. There is no scarcity of natural gas and there is no scarcity of the technology to extract it from the earth. The only thing that is scarce is the political will to allow its extraction.

Here’s one more observation about the cost of producing hydrogen compared to producing natural gas. For all practical purposes, natural gas is ready to use once it comes out of the ground – after a few and relatively inexpensive purification processes. The major cost involved with the production of natural gas is drilling.

Hydrogen, on the other hand is abundant and readily accessible. Three-fourths of the earth’s surface is made of two hydrogen atoms combined to one oxygen atom. It’s everywhere and easy and inexpensive to “extract” from the earth unlike natural gas. However, even though it is easily extracted, the molecular bond between those two hydrogen atoms and one oxygen atom is VERY STRONG – one of the strongest bonds occurring in nature. The cost of breaking that bond is what makes the production of hydrogen so economically unviable, and there are no incipient technologies currently being developed that will change that within the next decade.

Water, water everywhere and not a drop to . . . burn.

Hydrogen combustion – green or gray – will not be a significant player in the heat treat industry for at least a decade. That’s not to say that some of our more forward-looking companies will not and should not start researching and developing technologies to help increase the economic incentive to produce, distribute, and use hydrogen. I know for a fact that there are a number of combustion companies already heavily investing in this way. More power to them. I’m looking forward to the day when I can fill up my vehicle with water and drive 500 miles, and I’m sure there are heat treaters who would love to fuel their furnaces and drinking fountains from the same source.