In today’s article, Heat Treat Today’s editorial staff has gathered noteworthy reflections of heat treaters who are looking to the past to offer hope to present circumstances. Read more to see that while the present seems paused with Covid-19, the past offers promise of growth and change through challenges.

In today’s article, Heat Treat Today’s editorial staff has gathered noteworthy reflections of heat treaters who are looking to the past to offer hope to present circumstances. Read more to see that while the present seems paused with Covid-19, the past offers promise of growth and change through challenges.

Like many markets, the heat treating industry is seeking to make the best out of this summer of 2020, and even though the market is looking more positive by the day, there are many who still look for a sense of normalcy. However, with leaders looking at historical moments in heat treat, they remind us that while the present seems paused with Covid-19, the past offers promise of growth and change through the challenges of life.

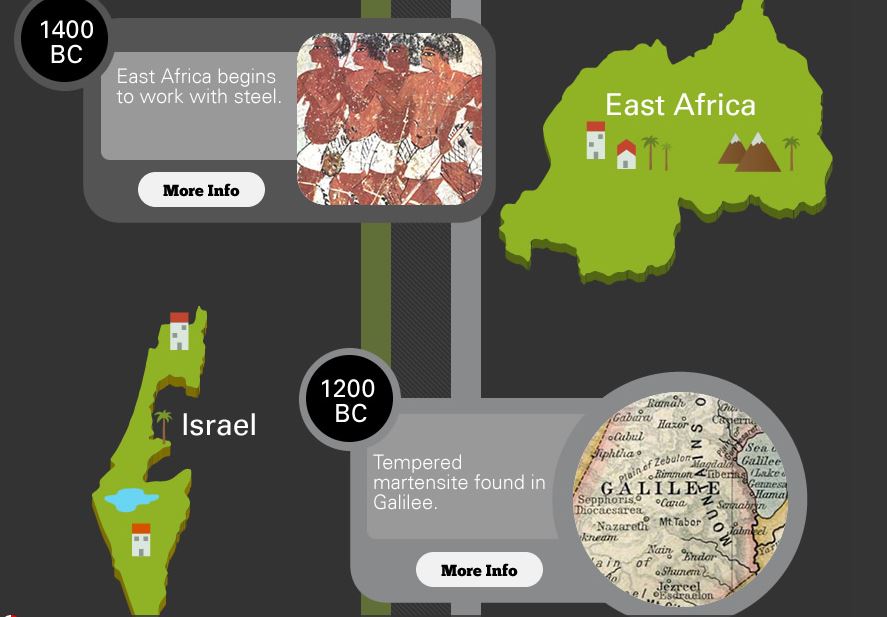

A major reach into the past is a throwback to the 90th century BC called “An Interactive History of Metallurgy.” In this historical timeline, Bodycote presents an engaging look at copper, bronze, iron, and tin through the centuries. The developments include detailed information, mostly funneled from Wikipedia, like the fact that bronze alloy in 12th century English candlesticks contained a degree of silver, antimony, and arsenic. And the modern, continuous development of steel is believed to have begun in the carbon furnaces of Sub-Saharan African communities.

On June 30, 2020, SECO/WARWICK released an “anniversary reflection” to commemorate the achievements of the Group in the first half of 2020. Among these is the 10th anniversary of their Chinese branch which has now become a recognized leader of CAB systems in heat treat, creating furnaces for aluminum brazing in controlled atmospheres. They conclude their message with a word from Sławomir Woźniak, President of the Management Board, saying, “We wish that health, patience and faith – embracing the world at large – will return to normal.”

Finally, a recent LinkedIn post from Shane Higgins, Field Sales from Special Quality Alloys Ltd, shared a lunch-time crowd favorite: Sanderson’s Weir, built in the 1580s. With two iron forges on either side of the River Don in Sheffield, this low dam was built to provide power to the industrial work. Changes in the nature of industry has allowed a 20-year project along the River Don in Sheffield and Rotherham to permit a fish pass for salmon after 200 years without. It is impressive that the location that once produced iron still houses metalworking business.