Heat Treat Today is partnering with two international publications: heat processing, a Vulkan-Verlag GmbH publication that serves mostly the European and Asian heat treat markets, and Furnaces International, a Quartz Business Media publication that primarily serves the English-speaking globe. Through these partnerships, we are sharing the latest news, tech tips, and cutting-edge articles that will serve our audience — manufacturers with in-house heat treat.

Take a look at new tech and equipment, an old furnace, positive profits and reports, and lasting partnerships.

International Heat Treat and Metallurgy Company Sees Doubling Profits

SECO/WARWICK’s positive figures for 2022

Source: SECO/WARWICK

“The great results of the Group were influenced by several factors. The growth of production activities in China and dynamic market development in America. Furthermore, the huge number of orders [are] related to the electromobility industry expansion. In the first three quarters of 2022, the company had over 100% more profit than in the previous year. Sales revenues amounted to PLN 448.87 million in this period (PLN 335.09 million in 2021). . . For SECO/WARWICK, 2023 will be the year of American companies.”

Read More: “SECO/WARWICK Group doubles its profits in 2022” at heat-processing.com

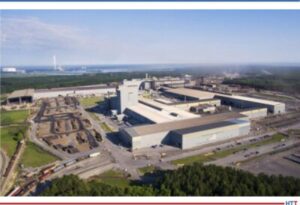

New Electric Arc Furnace in North America

System aids in the production of various steel grades

Source: Tenova

“Tenova, supplier of sustainable solutions for the metals industry, has recently completed the start-up of the new 70t EAF at the Valbruna ASW Inc. plant, located in Ontario, Canada. Valbruna ASW is a specialty steel producer that produces steel and stainless-steel, based in Ontario. Tenova’s latest generation EAF unit has replaced an older EAF vessel. The spout shape of the new furnace will provide an increase in melt shop productivity, says Tenova, as well as an improvement to the

production reliability of manufacturing specific high-quality steel and stainless-steel grades.”

Read More: “Tenova supplies Canadian EAF” at furnaces-international.com

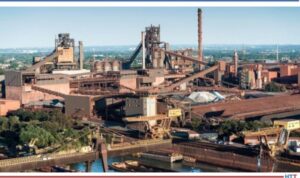

The Black Giant Turns 50

German blast furnace is 50

Source: Furnaces International

“A blast furnace in operation at thyssenkrupp Steel’s Schwelgern steel mill in Germany, turned 50 years old on 6 February. Known officially as Schwelgern 1 – the Black Giant – the blast furnace is 110 meters in height and has a daily capacity of 10kt of pig iron; it is regarded as one of the biggest blast furnaces in the western world.”

Read More: “Thyssenkrupp Steel’s Black Giant blast furnace turns 50!” at furnaces-international.com

Hydrogen-based Steel Production Project, SALCOS, Receives Gov’t Funding

German steelmaker awarded government funds

Source: Salzgitter

“Salzgitter, Germany’s second-largest steelmaker, has been awarded almost €1billion in government funding for its hydrogen-based steel production project, SALCOS . . . The project will produce around 1.9Mt of raw steel and cut more than 2.5Mt of carbon emissions a year, according to Germany’s economy ministry.”

Read More: “Salzgitter awarded €1b for hydrogen-based production” at furnaces-international.com

Foundry Group BIRN Released Its First Sustainability Report

Sustainability Report for BIRN Group

Source: BIRN

“As one of the first in its industry, the foundry group BIRN Group has just released its first sustainability report. The report is an initial step towards a more sustainable business model.”

Read More: “Foundry Group launches first sustainability report” at heat-processing.com

New Pyrometer for Foundry and Liquid Metal Applications

SPOT MM smart application pyrometer

Source: AMETEK Land

“Liquid steel and metal foundry and tapping operators can now benefit from improved and smart temperature measurements for process control and product quality improvements with the new smart SPOT Meltmaster (MM) application pyrometer from AMETEK Land. The SPOT MM offers a single-sensor solution for liquid metal temperature measurements in foundry and tapping applications. This smart application pyrometer accurately measures tapping stream and liquid steel and metal temperatures independent of surface and condition changes during the process.”

Read More: “New SPOT MM Smart Application Pyrometer from AMETEK Land” at furnaces-international.com

Specialty Steel Provider Joins Steel Manufacturers Association

Mike Williams, President/CEO

TimkenSteel

Source: TimkenSteel

“TimkenSteel has joined the Steel Manufacturers Association (SMA) – the largest steel industry trade association in the United States and is the primary trade association representing North American EAF steel producers. Timken’s president and chief executive offi cer, Mike Williams, has joined the SMA’s board of directors.”

Read More: “TimkenSteel Corporation joins Steel Manufacturers Association” at furnaces-international.com

Nucor Steel Orders Hot-Dip Galvanizing Line

Nucor Steel Berkeley has ordered a new plant for its steelworks from Primetals Technologies

Source: Nucor Steel Berkeley

“Primetals Technologies has received an order from Nucor Steel Berkeley, a division of US steelmaker Nucor Corporation, for a new hot-dip galvanising (FVZ) line for the automotive industry. The line will be installed at Nucor’s plant in Huger, South Carolina. Nucor Corporation is the largest steel producer in North America and the largest recycler of materials in the Americas.”

Read More: “Primetals: Nucor Steel orders hot-dip galvanising line” at heat-processing.com

New Electrical Steel Lines for EV Motors

Investing in the production of high-performance electrical steel in Shanghai.

Source: Baowa

“Fives, a leading engineering group with broad expertise in steel processing and technology, has designed and delivered thermal sections for a new annealing and pickling line (APL) and two new annealing and coating lines (ACL). The lines, designed to produce high quality non-grain oriented (NGO) grades for electric vehicle motors, delivered their first coil between December 2022 and February 2023.”

Read More: “Fives and Baowu launch new electrical steel line” at heat-processing.com

Successful Trials Will Help Manufacturer Reduce Carbon Footprint

Addressing the issue of plastic waste management.

Source: worldsteel

“Integrated steel manufacturer JSW Steel has accomplished a ‘significant breakthrough in environmental sustainability’ by successfully injecting waste plastic into Blast Furnace 3 at its Vijayanagar steel plant following extensive trials.”

Read More: “JSW Steel successfully completes waste plastic injection trials” at furnaces-international.com

AICHELIN Cooperation Agreement

Left to right: Huang Ligang, general manager, Kilnpartner; Zhang Yuejin, Chairman of the board, Kilnpartner; Michael Reisner, CEO, Aichelin Ges.m.b.H.; Christian Grosspointner, CEO, Aichelin Holding; and Fan Xiaochun, CEO, Kilnpartner, after signing the contract.

Source: Aichelin

“The thermal processes used to treat the essential components of Li-ion batteries represent a key technology in this process. These include the cathode as LFP (lithium iron phosphate) or NMC (nickel manganese cobalt) and the active anode material. Only through a highly accurate heat treatment can the crystal structure and morphology of the material be trimmed to “peak performance.” In order to achieve this goal, each manufacturer has its own processes. The common basic requirement is flexible and reliable plant technology, the so-called “kilns.”

Read More: “New heat treatment cooperation for battery materials” at heat-processing.com