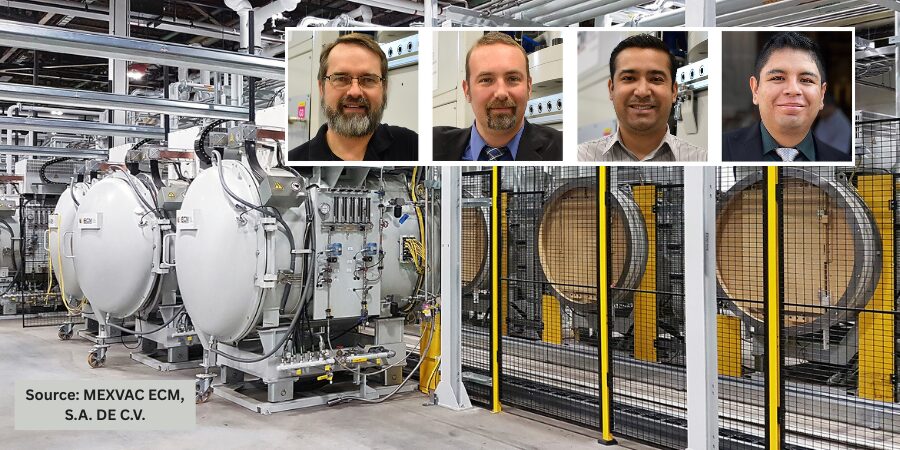

Source: Advanced Heat Treat Corp.

Nitriding and nitrocarburizing may be familiar terms in the industry, but which process — ion/plasma nitriding, gas nitriding, or nitrocarburizing — is best for your heat treat operations?

In this best of the web article from Advanced Heat Treat Corp., discover the specifics of each of these surface treatments and compare their benefits for wear resistance and corrosion resistance. Explore also the innovative technologies developed by the North American heat treater for optimization of these processes. for optimization of these processes. You will encounter technical diagrams, high quality images of nitrided/nitrocarburized parts, and in-depth technical comparisons of these processes.

An excerpt:

Well-controlled nitriding significantly enhances wear resistance and lowers coefficient of friction in many applications of steel components. For certain steels, nitrided samples show even better tribological behavior than carburized samples of the same steels.

Read more: “Wear and Corrosion Resistance: Benefits of Plasma Nitriding, Gas Nitriding and Nitrocarburizing“