An investment castings manufacturer's heat treat department received a large floor-standing box furnace from a North American specialty furnace company. The furnace will be used as support in the client's tool and die production along with tempering of finished castings.

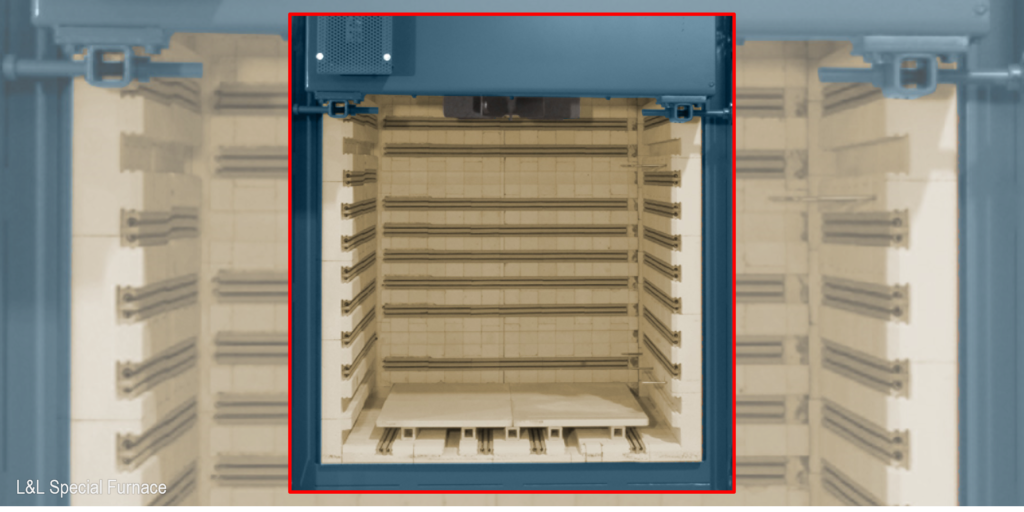

The L&L model XLE3436 box furnace from L&L Special Furnace has an effective work zone of 34” wide by 22” high by 32” deep. It is equipped with a direct-lift vertical door with a floor switch to activate. The cantilevered vertical door eliminates the need for the upright structure to reduce the overall height of the equipment.

Tom Schulz, sales manager at L&L, highlights the key role this will play for the heat treat department, saying that this type of furnace is the company's “workhorse when it comes to thermal processing.”

The inert blanketing gas enables the part to be heat-treated with minimal surface de-carb. A stack light indicates the furnace status via an audible and visual indicator light mounted on top of the control.

Additionally, the furnace is equipped with a pyrometry package that has reference control thermocouple ports along with corner locations to record the high and low points within the unit as indicated by the latest temperature uniformity survey.

The original press release from L&L Special Furnace is available upon request.