Watlow®, a designer and manufacturer of complete industrial thermal systems, has recently completed its acquisition of Eurotherm®, a provider of controls, systems, software, and services for industrial markets around the world. How did the acquisition happen, what future technologies can we expect, and what should heat treaters know about this change?

Joining Doug Glenn, Heat Treat Today publisher and Heat Treat Radio host, is Watlow CEO Rob Gilmore to answer all your questions.

Below, you can watch the video, listen to the podcast by clicking on the audio play button, or read an edited transcript.

The following transcript has been edited for your reading enjoyment.

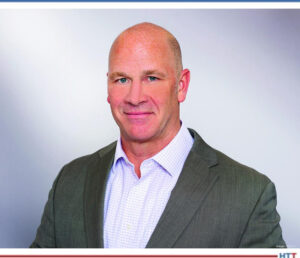

Who Is Rob Gilmore? (00:43)

CEO

Watlow

Source: Watlow

Doug Glenn: Welcome everyone. Doug Glenn here, with Heat Treat Today. I have the great privilege of talking with Rob Gilmore, CEO of Watlow. I’m excited to talk with you, Rob. We’ve got quite a bit to cover today, so let me just jump in.

First off, I want to talk about you to give our listeners a sense of you and your background. I wasn’t stalking you, but I was doing a little bit of research, and I was pretty impressed.

I’ve got a list of titles here of things you’ve done at Watlow for the last 35 years: co-op student intern — that’s where you started, which is crazy — and then R&D, product development, manufacturing, engineer, design, development manager, operations product manager, semiconductor business group manager — where you spent a good bit of time — and VP and chief. So, tell us all about your experience at Watlow.

Robert Gilmore: Yes, I’ve had an exciting journey at Watlow and was fortunate enough to get started early in my career and figure out that I wanted to be in engineering. When I first started in engineering, I wasn’t too sure that was what I wanted to do, but when I started with Watlow, it definitely validated that this was it.

I was fortunate enough to get in the R&D group and learn a lot about both thermal applications and how to apply electric heat. It just continued to draw me to it. After I got into developing a lot of products, I entered into the manufacturing side to make sure I knew how we built those products. Then I really got to spend a lot of time with customers and customers’ applications to provide good solutions and solid solutions to our customers.

Doug Glenn: We’re going to get into a little bit of the Watlow company history here. Most recently, in 2021, you became CEO of Watlow, worldwide, correct?

Robert Gilmore: That is correct. We were fortunate to get partnered with a company called to really help us really accelerate and advance our strategy in the business.

About 10–12 years ago, we really knew that the thermal loop coming together was really going to help us optimize our customers’ applications around process heating and heat treat. We’ve seen a lot of success in that arena, and we knew that we wanted to invest much more capital into the business and help our customers be successful in those applications.

Doug Glenn: I want to talk a little bit more about Tinicum in a minute, but I think I heard that you, at one point in time, worked with or for Lindberg.

Robert Gilmore: Actually, it was early in my career, right after college. Lindberg was a very important customer of ours that was dealing with heat treat and furnaces, and they challenged us with some key applications.

My boss — this is a little bit of history of how I learned a lot about heat treat — said, “They’ve (Lindberg) got some significant thermal challenges and I’m going to drop you off here and don’t come back until you figure out how to solve those thermal challenges.”

I’ve always had a passion for heat treat and heat treat applications because they are the most challenging. I learned a lot about the application and how to optimize it.

Doug Glenn: And that was Lindberg rg, the commercial heat treat company, yes?

Robert Gilmore: I think it was actually their equipment manufacturing company.

They definitely did a lot in the auto industry, and there were really some challenging applications.

Doug Glenn : You have a decent amount of heat treat experience if you’ve been working with companies like Lindberg. That’s really good.

And, by the way, I just wanted to make one other comment: I think you’re in a rare class as somebody who has worked for the company for 35 years. That’s just really unheard of.

Robert Gilmore: Yes, it’s been a great company. We’ve been fortunate enough that the family atmosphere, the opportunity to do a lot of different things in the organization, and the ability learn a lot in the organization made it attractive. And it’s not only me; we’ve got a lot of talent in the business with years of service, application knowledge, and capabilities. It’s just been a great experience.

Doug Glenn: I think it speaks to the man, somebody who sticks around that long, as well as the company culture.

Meet Watlow (06:05)

Let’s talk about Watlow for a while.

I know a lot of people in our industry know Eurotherm and a lot of people know Watlow. Watlow hasn’t been as “core,” let’s say, to the heat treat, high temperature, thermal processing market as Eurotherm might have been.

Robert Gilmore: The headquarters are in St. Louis, but we’ve quickly become a pretty global organization organization over the past five years. That’s why we made some of the decisions that we did; our customers are global — they’re expecting to be supported globally.

So, we’re in headquarters. But that being said, I like to tell people it used to be 75% of our employees were in the Midwest, but now, 75% are outside the U.S., looking at the growth and the acquisitions that we’ve made in business.

Doug Glenn: I saw that the company was founded in 1922. So, just last year, you guys celebrated 100 years.

Robert Gilmore: That’s correct. It’s been a great journey for the company. It’s a great, rich history of solving thermal problems over the years. It’s a fun organization, from that perspective.

Doug Glenn : It was very impressive. I know now, it’s said there are at least 14 different sites around the globe — manufacturing, development, sales, service, etc.

Robert Gilmore: At least 14 different manufacturing sites, and then probably additional sales offices and development offices across the globe.

Doug Glenn: And Watlow, the core business encapsulates heaters, temperature controls, temperature sensors. How would you describe the core business of Watlow?

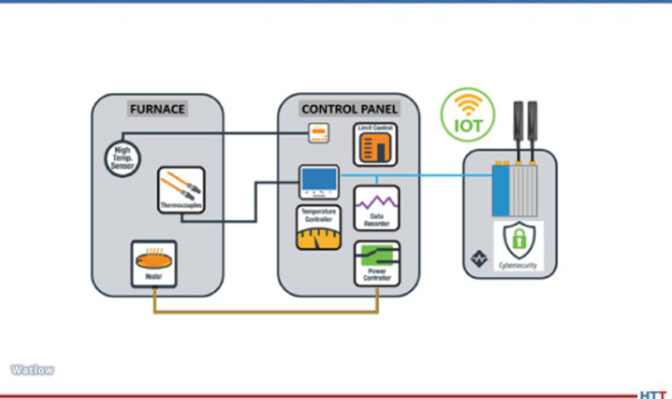

Robert Gilmore: Yes, I would say we look at it as a complete electric thermal loop. So, if you look at heaters, sensors, power devices, power management devices, along with temperature controls. That is the context of that thermal loop.

Doug Glenn: Gotcha. And then we did mention earlier, it was a family-owned business up until 2021, right?

Robert Gilmore: 2021, yes, is when we partnered with Tinicum.

Doug Glenn: Which is a private equity firm.

Robert Gilmore: Tinicum is more family oriented and it’s one of the reasons we partnered with them. But many of the family stayed in the business, just in a minority, shareholder position.

As Watlow started to advance its strategy, really around 2010, the goal was to bring the thermal loop together.

So, there was an acquisition in 2013 called Semiconductor Tooling Services (STS) and then there was the acquisition of Yarbrough that happened in 2018, and then CRC Inc. happened in 2020.

Doug Glenn: And there were a lot of product introductions. I was very impressed, looking down through the Watlow history on your website, seeing the amount of new products and services and acquisitions and expansions into various countries.

The bottom line is you are a global presence.

Robert Gilmore: We pride ourselves in being able to solve complicated thermal problems. We’ve got a very rich history of having solid technical and engineering talent, so usually if somebody can’t figure it out, they call us and we help them figure it out and work with them through that.

Key Markets (11:14)

Doug Glenn: Rob, if you don’t mind, could you just hit on some of the key markets? I know, obviously, you’re not all heat treat. I know you’re doing semiconductors.

In fact, I found it very interesting, by the way, as I was looking at your history, that you started out with shoes, some sort of a shoe heater.

Robert Gilmore: Yes, if you look at the history, the founder of the business recognized there was a way to mold leather more efficiently with an electric heater, and he created the electric heater (versus steam heating) in those applications. That’s how the business took off.

Over the years, we have continued to develop new products and new solutions as electric became more of an attractive solution. We pride ourselves in bringing the together.

Doug Glenn: Let’s talk about Watlow, not Eurotherm quite yet. Are there any major initiatives that you’ve got going on now?

Robert Gilmore: Yes. As Watlow was growing up as an organization, we were very product-centric, so we sold our components into a lot industries. Ten years ago, we decided that if we brought the thermal loop together to our customers, and targeted applications that had thermal challenges in there, we could bring a better solution to their process or their equipment in those applications.

That got us started on more of a market and application focus, starting with semiconductors.

That’s been the mantra. As we find that thermal is important in these different applications, we focus on those applications and provide those solutions.

So, the semiconductor has definitely been attractive. When you look at refrigerated transport and some of these markets looking for a cleaner, more efficient, alternative (what I would call “the diesel engine market”), we find that in cases where we have the opportunity to use the thermal system to increase fuel efficiency or make the engine burn much cleaner, that we’re helping our customers solve such problems.

There has been a big initiative to move from fossil fuel solutions to electric solutions. We see a lot of opportunities where we can help customers come up with more advanced heat exchanger solutions to optimize and provide a more efficient thermal solution to those applications. So, we’re helping many customers solve those applications.

We’re in medical. We’re in a lot of food processing, food equipment, as you might guess.

But we try to focus on those challenging applications where thermal is critical to the process or to the equipment, and help those customers optimize those solutions.

Green Initiatives and the Electric Thermal Loop (14:36)

Doug Glenn: You hit on one thing that I was going to ask you about: the green initiative, and if that’s really played well for you guys. Would you say yes to that?

Robert Gilmore: Absolutely. When you think about emissions reductions or clean energy, thermal is critical in those applications, and that is driving a lot of our products, solutions, and technologies. We’re helping customers solve those problems day in and day out.

Doug Glenn: Could you give our listeners any sense of magnitude or size of Watlow, whether it be total number of employees, annual sales, or profit margin — just kidding on that last one.

Robert Gilmore: We have around 4,000 employees, plus or minus, at any one time, and growing fast. I probably got that number wrong. We’re probably approaching a billion dollars in revenue. I might have to think about whether I want to share that or not, but it kind of gives you a relative size of the organization. We’re invested heavily in a lot of the products and technologies and supporting our customers, right now, to try to scale the business globally.

Doug Glenn: Returning to the “green” topic I asked you about, there was a term you continually mentioned. It may be a term that you’re using there at Watlow that some of our readers and I might not understand: the concept of the “electric thermal loop.” Can you address that? What do you mean by that?

Robert Gilmore: Electric has been prevailing for a number of years, but when we look at the electric thermal loop, it is descriptive of the heater engine, the sensing device, the power management system, and the control system. That’s what I call that loop.

The industry (whether OEMs or end-users) addresses thermal loop from a component mindset: somebody is providing the electric heater, somebody is providing the control system, somebody is providing the sensor.

But we really find where we specialize is optimizing for the customer’s process or for the equipment to be optimized. That’s what we focus on. That’s why I call it the thermal loop. It’s, How do I optimize process performance or application performance by focusing on ? Am I getting a real sense of management process temperature or safety limits that we have to control, because we’ve got a volatile gas or something of that nature? So, we try to optimize that thermal loop; that’s the job that we do.

Doug Glenn: That makes sense. And, also, I can see how there would be value there to your engineer-based clients in that they can come to one place and you can say, “Okay, listen, we can help create the heat, we can apply the heat, we can measure and control it.”

Robert Gilmore: That’s correct, yes.

What the Acquisition of Eurotherm Offers Heat Treaters (18:40)

Doug Glenn : Let’s jump to Eurotherm. The acquisition of Eurotherm happened in 2022, which was just last year. It seemed like a long time ago, but it wasn’t all that long ago.

Robert Gilmore: Yes, it’s gone by fast, and we’re coming up on a one-year anniversary.

Doug Glenn: So, if you can take yourself back a year or maybe even two, when you first started looking at that acquisition, at the time, Eurotherm was part of Schneider Electric, which is a huge international conglomerate. What was appealing to you guys and where did you think you were going to take this thing?

Robert Gilmore: Eurotherm had been on Watlow’s radar for a number of years. We valued them as a market leader and a competitor in the marketplace, especially when it comes to the controls and the power management space. We always viewed them as being a leader on many fronts, from the product and technology side.

As we got closer, we also acknowledged that they were in some attractive adjacent markets that we thought we could use to complement their technology and capability to help us grow in scale in the business. Then, as we got to know them a little bit better, we recognized the talent and the capability that they had.

Watlow serves a lot of OEMs. OEMs are probably the majority of our business. Eurotherm leans more towards what we would call “the end-user market.” They’re really knowledgeable about these key applications and markets. They know what customers are doing in those applications. We found that very attractive, and when we were able to acquire them, we got a wealth of talent and knowledge around markets and applications, as well as the products that we were attracted to as well.

Also, it increases our presence in Europe and Asia. It’s a good complement from that perspective.

We’re pretty excited about having them on board. We’re finding opportunities, all the time, to help our customers solve these applications. Now that those team members have access to our heating and sensing technology, that really gives them the full thermal loop to help support their customers. It’s a great complement to the business.

Doug Glenn: Yes. That’s very interesting. Before the acquisition of Eurotherm, Watlow was doing thermal controls of some sort?

Robert Gilmore: Yes. We’ve been in the controls business and power business for quite some time. When you look at the thermal loop, the way I phrase it is “the brains” of the thermal loop are in the control and power management side of the business. I’d like to say that’s the tip of the spear of what we’re doing for our customers, and our strategy is to bring that together.

Doug Glenn: I know that Eurotherm (and I’m wondering if this is another one of the reasons why you found them attractive) has systemwide, companywide-type controls and data acquisition, data management, and that type of thing. Did that capability play into the decision?

Robert Gilmore: Absolutely. That’s probably a really solid strength that they have around the data management acquisition side of their business. As we continue to make this thermal loop much more intelligent, access to data, data/data management, and data processing really becomes a really key value driver for us in the business.

It’s really very complementary to what we would say is on our roadmap: helping people implement Industry 4.0 and having that thermal loop intelligence in the system is really critical for where we’re going and how we’re helping our customers.

Integrating Industry 4.0 Technologies for Clients (23:07)

Doug Glenn : Can you speak to 4.0, either from the Watlow side or in combination with Eurotherm, along with things that might be coming up?

Robert Gilmore: When you look at our continued advancement and our bringing more advanced thermal loop and thermal processes together, data/data management/real-time data acquisition, and allowing that thermal loop to be more intelligent, real-time, feed the process

We actually have a portfolio of what we would call I-40 technologies that are helping our customers manage their systems and process more effectively. We’re in a lot of alpha and beta testing right now, with several of our customers, to help them advance their systems and solutions, as well.

Obstacles and Initiatives (24:03)

Doug Glenn: I assume the acquisition/integration of Eurotherm has gone relatively smoothly.

Robert Gilmore: It’s gone perfectly.

Doug Glenn: Never a misstep, I know!

Robert Gilmore: It’s been a great learning experience with the team. We’re coming together and figuring out how to work together. We’re trying to focus on our customers and our opportunities and then we’ll find it easier to work together. But I’m actually very happy with how things are going, with how the teams are working and really seizing the opportunity.

Doug Glenn: Good, good. Well, you know, in the years that I’ve been in the business, I’ve developed a decent knowledge of some of the people at Eurotherm, and I will second what you’re saying — you’ve got some good people and some good talent there.

So Rob, how about market obstacles, at this point? What are the things keeping you up at night?

Robert Gilmore: I think there are always going to be some of these challenges that are in front of us, with a business that’s growing like ours. We just continue to make sure that we’re developing and bringing on new talent and developing them to support the business and our customers. I think that’s always going to be a challenge.

In terms of these initiatives and where those opportunities are and which ones to focus on, a challenge is that different parts of the world are regulating differently, which makes us support faster. Predicting how those outcomes are going to happen and seeing what we should focus on first is always a challenge. We do not lack opportunity for business and growth opportunities.

But, you know, as much as those are obstacles, I look at those as great opportunities that are in front of us, as well.

Doug Glenn: Right. We had a team meeting here the other day with our team and somebody brought up the saying that Billie Jean King used to say, “Pressure is a privilege.” So, you know, you’ve got a lot of stuff going on and it’s a nice problem to have, to be able to say, “Well, which one of these is the best one to take?” and have to make that decision.

We’re coming towards the end here, Rob. How about any specific initiatives with Eurotherm into either the heat treat market specifically or Eurotherm generally, that our listeners might want to know about?

Robert Gilmore: Yes, we’re continuing to advance the strategies in these different markets. Definitely in the heat treat market, we are coming together and really having specific strategies around that, and how we can optimize the thermal loop and those applications.

But really what I’m probably most excited about is the continued investment we have in technologies and products. We see a next generation of control and power management devices along with data acquisitions that you will start to see come out in 2024 and 2025.

We continue to invest in technology platforms, in what we would call the I-40 technologies platforms. We also have some, what I would call “advanced adaptive thermal systems,” that really allow the thermal loop to be intelligent.

We’ve been launching different products over the last probably five years, and more to come from that perspective.

And I’m pretty excited about some of the heater and sensing technologies that we’re developing, which include higher temp capabilities. The temperatures are going to continue to increase in some of these applications and become more demanding, and we’ve got some interesting technologies that we will be advancing there.

I think a big thing we’re also launching in a lot of alpha and beta applications, right now, has to do with “medium voltage technology.” As you continue to see this movement from fossil fuels to electric, the low voltage solutions don’t generate enough power, and we are introducing what we will call a medium voltage technology and heater technology. So, the ability to move from 480 to 600 volts to 4200 or 7200 volts is really going to give our customers the capability to handle going to those megawatt solutions that we can help them do.

I’m pretty excited about those technologies. We’ve been introducing some of those neat technologies that are going to help our customers be successful in many of these applications. It’s some pretty exciting stuff, at least for a lonely old engineer like myself.

Doug Glenn: For electric thermal loop geeks, this is great stuff.

Robert Gilmore: Absolutely.

Doug Glenn: I will tell you, And the whole green initiative seems to be global now. We were at THERMPROCESS over in GIFA in Düsseldorf, and it was all about green initiatives.

These are interesting times and I think you guys, with your business strategy, seem to be very, very well positioned to reap the benefits.

Robert Gilmore: We are definitely excited about what we’re doing today and what we’ll be doing tomorrow. These are exciting times for Watlow.

Doug Glenn: I have one other question for you: Are you guys doing anything with AI that you’re able to talk about?

Robert Gilmore: We definitely see opportunities from that perspective. We definitely believe it’s going to help — and it is helping — support our business. I would say probably we’re in the throws of really the ability to leverage the wealth of knowledge that we have and be able to get that through our business and our team members.

Again, I can’t even imagine the number of years of talent and technology and industry leaders in our business, and I want to make sure that knowledge gets transferred on to the next generation. I think we are looking at AI, in many ways, as to how to accelerate that ability. That’s probably the only nugget I’m going to give away from that perspective.

Doug Glenn: Fair enough.

Robert Gilmore: I appreciate the time and the opportunity. I’m definitely excited that we’re going to continue to have more presence in the heat treat market; you’re going to see our name more and more.

We’re pretty excited about the future and looking forward to talking to you some more.

Doug Glenn: If people want to keep up with you guys — what’s going on, what is the latest news out on you guys — is there any direction you want to steer? Is there anything you would recommend customers or prospects do?

Robert Gilmore: We’re continuing to advance and develop our website, and that’s a good place to start, if you want to reach out. Bob, or even myself sometimes, is always interested in what customers are thinking about or what help they need, as well.

Doug Glenn: Good, very good. Rob, thank you very much.

About the expert: Rob Gilmore has been with Watlow for nearly 35 years. Throughout his career Rob has gained broad experiences in engineering, manufacturing, product management, operations and general management. As a result, he has developed a keen understanding of the application of Watlow products, services, and solutions across a broad range of industries (including industrial ovens and furnaces). Prior to becoming CEO, Rob served as COO and general manager of the semiconductor processing business unit, growing this division to Watlow’s largest market segment. Shortly after Tinicum L.P. acquired a controlling interest in Watlow in March of 2021, he was promoted to Watlow’s CEO. Most recently, Rob has led the organization through the acquisition of Eurotherm from Schneider Electric in November of 2022.

To learn more about Rob, please reach out to Peter Sherwin at peter.sherwin@watlow.com or Bob Moore at BMoore@Watlow.com, or visit https://www.watlow.com/.

Learn more about this episode’s sponsor, Heat Treat Today Ebooks, at https://www.heattreattoday.com/ebooks/

To find other Heat Treat Radio episodes, go to www.heattreattoday.com/radio.