Sasha Tupalo, the manager of Thermatool Labs at Thermatool Corp., was recognized in 2019 as a 40 Under 40 rising star, and she has more than lived up to this award; she answers the call of leadership through educating others and managing a variety of projects. In this Heat Treat NextGen series (formerly called “Metallurgical Posterchild”), we join Doug Glenn, publisher of Heat Treat Today and host of this podcast, to learn what brought her to metallurgy, her training and leadership initiatives, and more.

Sasha Tupalo, the manager of Thermatool Labs at Thermatool Corp., was recognized in 2019 as a 40 Under 40 rising star, and she has more than lived up to this award; she answers the call of leadership through educating others and managing a variety of projects. In this Heat Treat NextGen series (formerly called “Metallurgical Posterchild”), we join Doug Glenn, publisher of Heat Treat Today and host of this podcast, to learn what brought her to metallurgy, her training and leadership initiatives, and more.

Below, you can watch the video, listen to the podcast by clicking on the audio play button, or read an edited transcript.

Meet Sasha Tupalo (01:08)

Doug Glenn: Welcome. I’m looking forward to the conversation.

Sasha Tupalo: Thank you so much for having me, Doug. It’s a great honor and pleasure.

Doug Glenn: Yes, great. And we should start off by mentioning that Sasha was in the 2019 class of Heat Treat Today’s 40 Under 40! Congratulations on that.

Sasha Tupalo: Thank you. That was a huge honor, as well.

Manager of Thermatool Labs

Thermatool Corp.

Source: LinkedIn

Doug Glenn: I want to get a little bit more about your background; we’re just getting to know you a little bit better because you’re one of the younger, rising leaders in the industry.

Where do you work right now? What’s your title, and what do you do?

Sasha Tupalo: I work at Thermatool Corporation, located in East Haven, Connecticut. We manufacture high frequency welders, heat treating equipment, as well as cutting equipment for the pipe and tube industry.

Doug Glenn: You guys are part of the Inductotherm Group of companies, correct?

Sasha Tupalo: Correct. Inductotherm Group consists of over 40 companies.

We have different divisions for melting and heat treating.

Doug Glenn: For those in the heat treating industry, we might be a little more familiar with companies like Inductoheat Inc., Radyne Corporation, Lepel … there are a number of them.

You are the manager of the lab?

Sasha Tupalo: Yes. My current title is manager of Thermatool Labs. Thermatool Labs is a characterization laboratory here at Thermatool where we do studies from heat treating, weld sample analysis, any R&D projects involving welding of new materials (perhaps with high frequency welding), creating heat treating recipes for our customers for post weld heat treating of seams or full body, annealing and heat treating. I have the most fun here!

Source: Thermatool Corp.

Doug Glenn: Yes, good — every day is exciting!

Sasha, I want to go, very briefly, through your upbringing, from where you were born, where you were raised, what your education was. Can you give us the, “I was born in _____” and up through college?

Sasha Tupalo: Absolutely. I was born and raised in Ukraine in the town of Dnipro. It’s kind of centrally located, right on the river. I went to high school there, and went to undergraduate school in my hometown, as well. Then I moved to the U.S. to pursue my master’s degree. Both my undergraduate degree and my master’s degree were in Material Science and Engineering.

Doug Glenn: And your undergraduate degree was from Ukraine, or did you get it here in the States?

Sasha Tupalo: It was from the Ukraine, my bachelor’s degree.

Doug Glenn: What year was it that you came to the U.S. for your master’s?

Sasha Tupalo: It was 2014. I had a gap year, actually. I got my bachelor’s degree in 2013, and then I had a gap year. When I was studying in undergrad school, I’d had an opportunity to come to the U.S. for two summers. There used to be an exchange student program, so I participated in that. After I received my bachelor's degree, I thought it would be really neat to get my education somewhere overseas.

Doug Glenn: So, where did you go for your master’s degree?

Source: Worcester Polytechnic Institute

Sasha Tupalo: For my master’s, I went to Worcester Polytech Institute in Worcester, Massachusetts.

Doug Glenn: At WPI with Richard Sisson and that crew.

Sasha Tupalo: He was my professor!

Doug Glenn: Yes, we know Dr. Sisson very well. He’s a nice man.

Sasha Tupalo: We collaborate on things, but he will always be Professor Sisson to me.

Doug Glenn: It’s difficult, once you know someone by their title, to call them by their first name.

Since you’re from Ukraine, it’s incumbent upon me to ask: Are your family and others all okay, that you know of?

Sasha Tupalo: That I know of, yes. My mom’s been fortunate enough to be staying with me for a little while. The rest of my family is still over there. Thankfully, they are okay. I mean, you know, it’s war, but it is difficult.

Doug Glenn: Well, as you know, a lot of people in the United States have our thoughts and prayers with the folks of Ukraine. They’re certainly taking it on the chin.

Sasha Tupalo: I would like to say, from the all the Ukrainian people I know, a lot of people are very, very grateful for your support.

Beginnings in Materials Science (06:10)

Doug Glenn: Thank you; I appreciate that.

Let’s talk about how you got interested in metallurgy. Here you are, a young high school student or so — what intrigued you with materials and metallurgy?

Sasha Tupalo: This is kind of funny, but it’s true: It was pure curiosity. I was graduating high school, and I was 16 at the time. I really had no clue what I wanted to do with my life, so I started going through majors. I had a list of things I knew I wasn’t as interested in — I knew I didn’t want to go into the medical field. My grandma was a doctor, but that’s just not for me. Law, also, was not for me.

My dad is an engineer. I was always good at math and sciences, so I considered engineering. I just didn’t know which kind of engineering. I started looking through lists of majors, and looking through different leaflets, and I found something that was called “materials engineering.” I was like, “Hmm, I’m curious.”

As I’m reading what it’s about, in a leaflet from the undergrad school where I went to, the first sentence was: “Just look around you. Everything that you see is made out of materials and this is what we study.” I thought, “Wow, that’s fascinating!” I started reading more, and I leaned more into metals — that was my choice of materials.

Doug Glenn: Any reason why metals?

Sasha Tupalo: No, not really. It’s just what fascinated me. As I started reading more and getting more into it, I said, “Wow, I want to study this. This is very, very interesting and unique.”

Doug Glenn: It’s an interesting and healthy perspective: you look around and you see, like you said, everything is all materials! So many people today want to go into computer sciences and similar things, stuff that you really have a hard time getting your hands on. But there is a real world out there made up of real things!

You mentioned that your grandmother was a doctor, and your father was an engineer. And your mother?

Sasha Tupalo: She is an English teacher, actually.

Doug Glenn: What did your family think when you said, “You know what? I think I’m going to go this materials/metals route.” Were they supportive, or did they say, “What were you thinking?”

Sasha Tupalo: My dad was very excited. He was, like, “Oh, another engineer in the family, that’s great!” He actually went to the same undergrad school as I did. For him, that was a very proud moment. My mom was supportive, but she was kind of scratching her head. She was, like, “If that’s what you want to do, just do it well. You’ll succeed.”

Source: Unsplash.com/thisisengineering

My grandma, she’s older, and she expressed, “I don’t think girls do engineering.” That was kind of the mindset. My grandma is 82 now, so, at the time, she just thought, “That’s an odd choice.” And really, when I went to school, there weren’t a whole lot of girls, especially in materials engineering.

Doug Glenn: It’s still relatively true.

Sasha Tupalo: Yes, it’s still true. At WPI, we actually had a pretty diverse group for our master’s degree; but once you get into metallurgy and the heat treating industry, it’s still predominantly a male industry.

Doug Glenn: The very first interview of this type that we did, in fact, the very first podcast that Heat Treat Today did, was with a female graduate from WPI. Her name was Hayley Sandgren (now Hayley Sandgren-Fox), and she was the very first podcast that we ever did.

Sasha Tupalo: That’s amazing!

Doug Glenn: It is. Years ago we did a survey of the thermal processing market. It was basically 98% male and 2% female. That was quite a few years ago, but I doubt that it’s changed significantly. If it’s 10–15% women, I would be surprised.

Sasha Tupalo: I think the latest research from the census bureau, that I’ve seen — in the workforce and STEM careers, it’s around 27–28% women.

Doug Glenn: Is that right?

Sasha Tupalo: Yes, something like that. And then, they have further distinguished between computer science and engineering; and the engineering numbers are quite low.

Sasha’s Experience in Heat Treating (10:55)

Doug Glenn: When you got to WPI, what did you study, specifically? What was your master’s thesis?

Sasha Tupalo: I had a master’s independent project. It was actually about heat treating: It was the microstructural and grain growth kinetics of 8620. It was a pretty neat project. It was very hands-on, which a lot of people who go to WPI will tell you that we really appreciate the projects the students have. They’re very involved; they’re hands-on. It gives you a better perspective of how to actually take what you’ve learned and bring it to the real world or to your job.

Doug Glenn: So, what is the application? I mean, is there a practical application of what you studied, or is it more theoretical?

Sasha Tupalo: It was pretty applicable just to the heat treating industry — austenitizing, quenching and tempering — grain growth kinetics, hardness variations, microstructural evolution. It’s actually all of the things I do now, so that was really helpful!

Doug Glenn: Workwise, specifically, what are some of the projects with which you’re involved?

Sasha Tupalo: I am very heavily involved on the high frequency induction welding side. That was something new to me, as I was graduating. I did a lot of continuing education in terms of welding, welding metallurgy, and now I’m the expert of high frequency induction welding.

Now, as far as the heat treating side goes, I am now involved in and looking into new 2-step, post-weld heat treating for high frequency induction welds to improve their toughness performance, especially for pipelines. Low temperature pipelines seem to be the trend these days, so we’re trying to help our customers to improve their Charpy properties.

Doug Glenn: Did you enjoy WPI?

Sasha Tupalo: Yes, absolutely. I had a really good experience.

Doug Glenn: What did you enjoy most? Was it the technical part, was it something outside of school, what was it?

Sasha Tupalo: Just the school itself, the campus. There’s a real sense of community at WPI. I had very good classmates and had a lot of, as I mentioned before, hands-on stuff, and practical training and seminars. It was very involved. It was nice to be in that atmosphere — where everybody is striving to do their best and learn something new.

Doug Glenn: After you got out, have you enjoyed the industry?

Sasha Tupalo: Yes. I enjoy industry very much so! There is something about putting your knowledge to actual, practical solutions that I really enjoy.

Doug Glenn: Do you get to go out into the field much? I know that you do R&D, but are you out in the field?

Sasha Tupalo: I do.

Doug Glenn: Tell us about that a little bit.

Sasha Tupalo: When I started at Thermatool, my first title was applications engineer, so I was traveling quite a bit. I would mostly visit our pipe and tube mills of our customers. They don’t differ much from steel mills.

Doug Glenn: You started as application engineer, and you are now lab manager? What was the progression there?

Sasha Tupalo: Applications engineer, materials engineer, senior materials engineer, and now lab manager.

Doug Glenn: You’ve been “climbing the corporate ladder.”

Industry Tips (15:50)

A couple other questions here: You mentioned that you continue to grow in your knowledge. If you were to recommend one helpful tool, for people similar to you in the industry, some sort of metallurgical resource or materials resource — do you have anything that’s a favorite?

Sasha Tupalo: I’d have to go with ASM. They have vast knowledge; they have classes and webinars; they publish books. There is just pretty much anything you might need, and you can find it. I have taken a couple of the classes myself because they were very niche; that’s not something you learn in school. I think if someone was looking for some resource, that’s a great resource.

Doug Glenn: Is there anything you would say, in way of encouragement, to younger people (I don’t know that many young people will be listening to this that aren’t in the industry already) but would there be anything you could say that would encourage people to say, “You know, you really ought to look into this industry”?

Source: Heat Treat Today

Sasha Tupalo: Yes. There are a lot of opportunities — and I’m sure you’ve heard it from other people too — we’re having a really hard time finding new workforce, especially younger people. There are lots of opportunities for growth. It’s fun. It’s a really fun industry — for me, it is, at least. If it’s something that interests you, I say go for it!

Rapid Fire Round (17:38)

Doug Glenn: Very good. This has been great, Sasha, we appreciate it. I want to wrap this up with maybe some stuff a little bit more away from business and education; just kind of some fun things to show people that, you know what, materials engineers are people too.

I’m going to give you a couple quick questions and you can give me a one-word answer, or you can give me an embellished answer. This is the “rapid fire round.”

Doug Glenn: Are you a MAC or a PC user?

Sasha Tupalo: I would have to go with PC. I’ve been a PC user since elementary school.

Doug Glenn: When you consume media (any type of media), what do you prefer — print or digital, both?

Sasha Tupalo: I would say both. I really enjoy getting email digests, either weekly or daily or whatever they are, but there is something about reading through an actual magazine, in print, that I prefer much better.

Doug Glenn: Very interesting. That’s great.

Which do you value more — I’m going to give you two options? Flexible work schedule or high pay? If you had to give up one or the other? Would you rather be paid high and have a rigid work schedule, or do you like the flexibility and maybe you’ll take a little pay cut for the flexibility?

Sasha Tupalo: I would probably say flexible schedule. It’s a tough one but . . . . I wonder if you would ask me that maybe 5 years from now if my answer would change. But, as of right now, it would be flexible schedule.

Doug Glenn: I ask that question because I’m a “baby boomer”; I was born in 1961, so I’m one of the old-timers, supposedly. I don’t feel like it, but they tell me I am. The stereotype is that we tend to be out for the higher paying jobs, but that the younger generation tends to be, “You know, money is not that important. I’m more interested in flexibility.” It has been interesting: Almost everybody, all of the younger people that we interview, most of them do say they’d rather have the flexibility. It’s not that money is not important.

Sasha Tupalo: Right. But if you have to choose one . . .

Doug Glenn: Yes, right, one or the other. It’s kind of an unfair question, but that’s okay; nobody said the questions were going to be fair.

The people at Thermatool, I’m sure, know that you love your job and that you’re not going anywhere. But, if money were no object whatsoever, what would be your dream job? If you didn’t have to worry about money, and you just did something you really enjoyed doing, what would you do?

Sasha Tupalo: I’ve never thought about it because I enjoy what I’m doing.

Doug Glenn: Yes, it could be that this is it!

Sasha Tupalo: Yes, this might be it for me!

Doug Glenn: So, nothing else? You’ve never thought, “You know, if I could just do this, that would be really interesting.”

Sasha Tupalo: No, I really haven’t, to be honest with you. I really enjoy being an engineer, working on solutions and being challenged.

Doug Glenn: Good for you. It’s good to be content.

So, outside of work, what occupies your time? Are you an outdoor person, or what do you do?

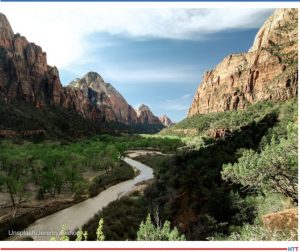

Source: Unsplash.com/Jeremy Bishop

Sasha Tupalo: Yes, I am. I really like hiking and camping. In fact, my husband and I are trying to visit all the national parks in the U.S. We’ve got a ways to go, but when we first started, there was 59 or 60 of them and now it’s up to 63. But we’ve got 20 on our list, so far.

Again, this doesn’t have to be technical, but can you tell us your favorite app, phone app, movie or magazine? Or you can give us one of each, if you’d like.

Sasha Tupalo: Favorite app? I guess I would go with the one that I use pretty much daily: I use Audible a lot lately.

Source: Unsplash.com/distingue

Doug Glenn: For audio books?

Sasha Tupalo: Correct, yes. I do so much reading for work, so when I do get a chance sometimes, I’ll do that. A lot of people do podcasts, and I do listen to some podcasts, as well, but I’ve found that audiobooks work for me too. And I can combine it if it’s commute or if I’m working out, I can do both.

Doug Glenn: So, how long is your commute?

Sasha Tupalo: Mine is actually not that long.

Doug Glenn: And what types of books are you listening to?

Sasha Tupalo: You know, same thing. I’m trying to be intriguing. I read a lot for work. I’m trying to go somewhere in a different direction. I’m working my way through the Game of Thrones series. I’m a little late to the party, but you know . . .

Doug Glenn: Very good, Sasha. It’s really been very much a pleasure to meet you and talk with you a bit. Congratulations, again, on the 40 Under 40 award.

Sasha Tupalo: It’s been a pleasure talking to you and thank you so much for having me.

Doug Glenn: You’re welcome.

About the expert: Sasha Tupalo began her career as a materials engineer at Thermatool Corp. in 2016 after finishing her master’s degree in Materials Science and Engineering at Worcester Polytechnic Institute. She has been very active supporting the Fabricators and Manufacturer’s Association educational programs, as well as ASM Heat Treat events. She provides process troubleshooting support for tube, pipe, and closed roll formed shape producers. She routinely evaluates weld samples and heat treat specimens as part of this process. Sasha delivers training both in-house at Thermatool and at customers’ sites and leads continuing education classes such as “Weldability of Advanced Steels, Stainless Steels and Aluminum” (delivered 2018 at LeTourneau University, Longview, TX), and “Oilfield Metallurgy” (an ASM Continuing Education Class) in 2017. She has written several papers and delivered presentations in her field just since 2016. Sasha is an active member of numerous scientific and technical committees such as ASM, ASTM (A01, E04 and E28), TMS, AIST and WAG (Welding Advisory Group) at AISI.

For more information: contact Sasha through the company website www.thermatool.com

To find other Heat Treat Radio episodes, go to www.heattreattoday.com/radio.