Heat Treat Radio host, Doug Glenn, interviews Greg Holland from eldec LLC on fluxless, inert atmosphere, induction brazing which could be a viable alternative to some flux-base furnace brazing applications.

Heat Treat Radio host, Doug Glenn, interviews Greg Holland from eldec LLC on fluxless, inert atmosphere, induction brazing which could be a viable alternative to some flux-base furnace brazing applications.

Below, you can either listen to the podcast by clicking on the audio play button, or you can read an edited version of the transcript.

Greg Holland (GH): I'm a sales engineer at eldec. My main duties are inside sales, marketing activities, trade show coordinating, as well as being a coordinator and scheduler for our in-house coil shop.

Source: eldec LLC

I've been in the induction industry here for about five years now. Prior to that, I spent time in both air filtration and the thin films industry. I feel that my experiences there have really given me a wide background. It's made me a well-rounded engineer, in my humble opinion, but it's also given me a lot of perspective and some background knowledge that some of my colleagues here don't necessarily have, which has been a good thing.

eldec was established in Germany in 1982 by a gentleman named Wolfgang Schwenk. In 1998, he packed his family up and moved here to Michigan. He established what was at the time eldec Induction USA in 1998. His goal was to better cover the North American market, and what better way to cover a market like that than to be in the market? He continued to have eldec in Europe, and then he started it here in the US.

In 2001, we moved into the building we're in now, and we've been here ever since. We've grown the facility a couple of times; in 2013, eldec, as a whole, was purchased by the EMAG Group from the machine tool industry, which I'm sure a lot of your listeners are familiar with. At that time, we changed our name to eldec LLC.

DG: Greg, is there an area of specialty that eldec focuses on, or is it “all things induction”?

GH: I would say all things induction. Our office, in particular, does not do a lot of the heat treating. That is handled by our sister company here in the US, EMAG. This is mainly because if they're selling the machine tools, they are typically the customers that are then looking to heat treat. So, it makes more sense for just one person to knock on the door. I'm not saying that we aren't versed in heat treating, we definitely are. Prior to 2013, all of that was sold out of our office in North America, and we have process development capabilities that, I would say, rival what our sister company EMAG has. They are also in the Detroit area.

DG: We're going to talk about something you and I have spoken a bit about, and that is induction, fluxless, inert atmosphere. Let's start at the very basics and work our way through. What is this thing we're talking about?

GH: When you're brazing in normal air, you end up with oxides on your parts. If you don't get the oxides off of your parts, then they end up in the joint between the metal layers and the alloy. A lot of times, people will use a flux. What we are looking to do here is to eliminate the need for that flux; so, we would use an inert atmosphere.

"We are looking to try to get rid of that flux because it adds steps in your process, meaning you have to apply the flux. Then afterward, you have to clean the flux off of the part. A lot of customers aren't afraid to do that, but it's cycle time, right? You have an extra step."

DG: Basically, we're talking about brazing in an atmosphere, using induction without flux, and the primary reason is to get rid of those oxides. You kind of answered this already, but why do we need it? Why do we need that type? What's wrong with using flux?

GH: A typical braze process would use that fluxing agent, so it's either an extra paste that you would put on, or in the event that you have your brazing copper, you would have maybe a silver alloy that would have phosphorous in there. That phosphorous acts as the flux. As the alloy melts the phosphorous, it interacts with the copper oxides and basically cleans the joint for you. It also allows the alloy to wet flow and fill the joint gaps.

We are looking to try to get rid of that flux because it adds steps in your process, meaning you have to apply the flux. Then afterward, you have to clean the flux off of the part. A lot of customers aren't afraid to do that, but it's cycle time, right? You have an extra step. So, it's time, or maybe it's an extra person, whatever the case may be. By eliminating that flux, you've eliminated those steps. You don't have to worry about cleaning the part afterwards, and if you're washing the parts to get the flux off, then you don't have to figure out what to do with that wastewater.

DG: Walk us through a typical braze process that uses flux. Let me try this and you tell me if I'm good. Basically, you've got to apply the flux, and then you also have to apply some sort of a braze paste, I would assume, correct? The actual filler material?

GH: Yes. You can use a paste. What we typically use is solid alloy. If you're brazing, say in tube brazing where your joints are round, a lot of the alloy will come as a ring. You can get it specially made from a supplier as a ring, so it slides right down over your tube. If you have plates that you're brazing together, you can get a foil. It's essentially a thin sheet that you can put between the plates. You can also use a stick form, almost like a welding stick or welding rod type. Or, if you have a trough that you're trying to braze, you can get it in pellet form--little solid pieces that will go down into that trough.

DG: So, if you were doing it with flux, you would apply a flux first, then those things, and then, of course, you'd have all of the cleanup of the flux afterwards, I assume.

GH: Correct. And typically, even before you put the flux on, you want to clean the parts and make sure that you don't have dirt and dust and other types of debris in there, too.

DG: It sounds like this brazing process, where it's fluxless, is replacing a standard flux-based brazing. We've already answered the question about the significance of fluxless; basically, you're not having to use that. The other part of the description is that it's in an inert atmosphere. I would imagine that everybody knows what an inert atmosphere is, but if you don't mind, explain what is inert atmosphere and why we need it for this process.

GH: By definition, an inert gas is essentially a gas that doesn't react with anything. You're looking at helium, argon, or nitrogen. Technically, an inert atmosphere could also be a vacuum. What the goal is here, amongst some other things, is to get the oxygen out and away from the joint. By using a vacuum, you have to essentially create a chamber that is airtight. Because, as you pull a vacuum, if it's not airtight, the oxygen in the normal atmosphere is going to be seeping into that chamber.

The advantage of an inert gas atmosphere is, by filling the chamber with a nitrogen or an argon, you essentially create a higher pressure in the chamber than you do in normal atmosphere, and so you don't have to be airtight. In all actuality, you don't want to be airtight because you want to be able to purge that space and allow the air that is in there to flow out.

DG: So, you're back filling. And, by the way, for those listening, we will put a link on the transcript of this podcast, to the video that you sent that actually shows that process. It's hard to see on radio!

GH: That's actually a process that we have as part of our trade show display. At various trade shows we'll have different displays, and that one in particular, is stainless steel brazing in an inert atmosphere.

Source: eldec LLC

DG: I'll describe it here just for a bit. Basically, there is a cylinder and they've got two parts inside that need to be brazed together. The cylinder, let's say it's a foot in diameter and maybe 16 or so inches tall, is a clear glass cylinder that comes down over the parts. I assume that you back fill with an argon or a nitrogen, and flush all of the oxygen out, and then it goes through a certain heating cycle and certain different KW and whatnot, and then cools at the end. Then, the lid lifts and you're off and running. That's basically how it looks

DG: Describe to us, if you don't mind, some of the industries that would use this process. What are the applications here?

GH: What we see is more so with stainless steel tube brazing, like fluid lines, automotive fuel lines, and that kind of a thing, where the end product doesn't get painted. It could be in an area that is visible to people, though, so they want it to look aesthetically pleasing. Those are the industries and processes where this gets used, but, ultimately, it can be used in any brazing application where you're currently using flux and don't want to have that additional step.

DG: You mentioned the automotive industry. Are there any other industries that you've seen it used in?

GH: We've had some other customers with essentially fittings on the end of a tube type of an application. I don't know what type of industries they ended up putting those into, but things like that are typically where we see these. But, again, it can be anything where you're heating, and honestly, it doesn't even have to be just brazing. If you have to heat something like that, you don't want to have the oxide layers and the discoloration. If you are back filling and purging that chamber with the inert gas, then as the part cools, and you allow it to cool in that inert atmosphere below the oxidation temperature, then you end up with a part that essentially doesn't even look like it was heated.

DG: Could this inert, fluxless, induction brazing potentially replace belt furnace brazing? Perhaps in some batch processes or torch brazing? Are there any savings in the process as far as manpower? I'm assuming you've still got to have somebody loading up the fixture to be brazed, right?

GH: Sure. You still have to have the fixture loaded. Depending on how the cell is laid out, it could be loaded manually, and it could be loaded by robot. You have some manpower requirements there. Typically, the actual loading isn't that much different than what you would have to do to load those parts into a fixture going through a belt furnace or to load them into a fixture heating them with a torch.

The advantage of induction over those two is not necessarily capital investment, but operating costs in the long run. You don't have the high cost of your gas. Typically, induction is more efficient than a furnace. It is a lot more efficient than a torch. You've got a guy out there with a torch that is heating your part, and then all of a sudden, he takes the torch and points it away as he does something else. All the while, the is gas burning, doing nothing. Again, with the furnace, whether you have a part flowing through there or not, you're heating that furnace and keeping it hot.

DG: Exactly. Whereas with induction, you're applying the heat and being done with it. Describe in a little bit more detail the actual process for an inert brazing process, fluxless.

GH: The chamber that you saw in the video is a large glass cylinder. They're not typically built like that. That one is built so that you can show it off and allow people to see what's actually going on. A lot of times, the chambers are much smaller. The goal is to make the space that you have to purge as small as possible, but still contain all areas of the part where the heat is going, because all of the space in that chamber has to be purged. That's an expense, so you want to limit that.

Now, depending on how long that purge cycle takes, how large your parts are, how long it takes to get to the temperature where oxidation starts to occur, you can start heating before the purge cycle is even done as long as you make sure that by the time you hit that oxidation temperature, all of the oxygen is gone. Then, you heat your part up to whatever temperature you need for your specific process.

Source: eldec LLC

In brazing, it depends on what type of alloy is being used and what your base metals are. And then, depending on how the coil design had to be designed for your process in your part shape, you might have to allow some additional soak time. Say you are putting a really weird-shaped fitting on the end of a part; you might not be able to get a full surround coil over the tube that's going into that fitting and realistically get that back out of the assembly. You might have a coil that only goes around 120 or 180 degrees, so to allow the heat to transfer around to the rest of that joint and come to a uniform temperature for the alloy to flow, a lot of times you have a little bit of a soak time. Which is what you see in that video, as well. After the soak time, the operator can typically see through a little window; or with our power supplies, we create a recipe with a set temperature, set power, whatever the case may be if you're using a pyrometer or not, and a specified length of time, and through a little bit of process development in the very beginning, we can create that recipe. So, from a push of a button, the operator doesn't even have to see, necessarily, whether the alloy is flowing or not.

We know for development you need this much power at this much time, maybe you need two or three steps at different powers and different times, and then, all of a sudden, you know that you're going to have a good joint, you shut the power off and allow the part to cool again in that inert atmosphere. If you're not worried about aesthetics, maybe you have a part that's going to get painted and the oxides are going to affect the adhesion of that paint, or you know that you're going to have to bead blast the part anyway, maybe you're not worried about it cooling in the atmosphere, in which case you don't have that cooling step, you can just open the chamber (but be careful because then you just have a hot part). You could essentially just open the chamber and pull that part out.

DG: Would you have to do it all in an inert atmosphere, if that were the case? If you weren't worried about the oxides, you could almost do it without, at all, right?

"What we typically see there, is we're up against a furnace brace and it boils down to not only capital investment, but operating costs in the long run, what the part volumes are."

GH: If you're just heating the part. But if you're looking to braze the part, you still either have to use the flux or the inert atmosphere to keep the oxide out of the joint area.

DG: It went through the cooling process, so now it's done.

GH: Yes, that's basically the process. Then, your chamber would open once the parts cool and your operator or your robot could unload the part and load the next one. Because of the purge and cool down time, a lot of customers will end up with a unit, a power supply, that has multiple outputs on it.

For example, we’ve built a unit with three outputs for a customer multiple times. So, in that particular case, there’s a part that has two or three different braze joint locations on it. However, what you are essentially looking at is the operator. Even if it's the exact same part in all three cases, the operator can load the part in one location, allow it to start purging, and then he can load the part in the next location. When the purge cycle is over, you can have that heat time automatically start with a self-controller.

So, the operator is literally just loading station after station, and when the first one is done, the second one is loaded, purged, and ready to heat; then the third one, and off you go. By the time the operator comes back to the first one, the part is cool, the chamber opens, and he takes it out.

Essentially, you just have an operator that is loading and unloading parts and you've saved all that cycle time by having a machine that is incrementally more capital investment but saves you so much in cycle time and process flow.

DG: Right. So, you're using that cooling time or soak time to do another function which keeps your production up. Can you tell us, without naming companies, any specific examples of where this was implemented and specifically what processes it might have replaced?

GH: The one that had the three outputs that I just talked about was for automotive fuel lines. Again, I can't say the customer’s name, and I can't say which OEM the parts actually went into, but I can tell you that it was automotive fuel lines. What we typically see there, is we're up against a furnace brace and it boils down to not only capital investment, but operating costs in the long run, what the part volumes are. If it's a car model that they don't sell a lot, then they may not be able to justify the capital cost of the induction, but if you're running typical automotive volumes, then the induction portion, split over however many hundreds of thousands of parts a year, is peanuts in the end.

DG: Do you have a sense of what the cost savings was per part or anything of that sort on that example you gave?

GH: Unfortunately, I don't. A lot of our customers don't share that kind of information.

DG: Wouldn't it be nice if they told you, because it would be a great selling point to be able to say, “Hey listen, they were furnace brazing these that cost them so much per part, now they're inert fluxless brazing with induction and it cost X minus whatever per part.” That would be a great marketing thing.

DG: I guess it's probably worth mentioning here that eldec does all different types of induction, not just inert, atmosphere, fluxless brazing, right? You're doing all kinds of different types of stuff. We were just focusing in on that specific process.

If people want to get in touch with you, Greg, or just to check out eldec, where do they want to go?

GH: We can be reached through our website. eldec actually has two different websites. We have a website that is essentially a worldwide website. I think there's eight different languages on it that you can choose from. That is www.eldec.net. On that website you'll see a lot of product lines and applications.

But here, specifically in North America, we have developed a site called www.inductionheatingexperts.com. That site is more tailored to our market here in North America. On that site, you won't necessarily see as much of the heat treating, because as I mentioned earlier, our sister company EMAG handles that. If you're interested in that, their website is www.emag.com. Here in our office, our main phone number is 248-364-4750 and our general email address is info@eldec-usa.com. Me personally, you can reach me at my desk at 248-630-7756 and my email address is gholland@emag.com.

DG: I did have one other question and that is what other resources are offered by eldec?

Source: www.inductionheatingexperts.com

GH: I mentioned our websites. Both websites will show a list of our products. There is at least one product line that is on the North America site that is not on the other site, and that's one that we developed and specifically developed here in North America. That's called our MiniMICO .

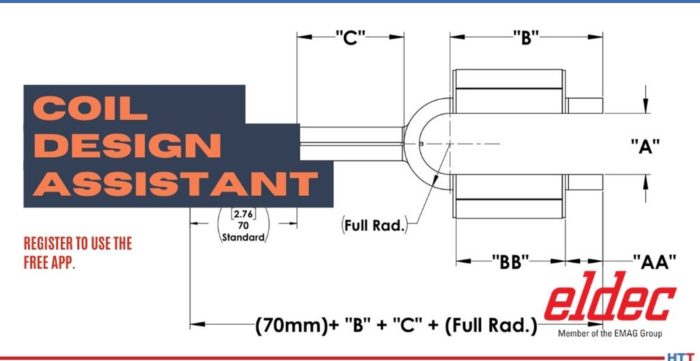

But also on our North American site is a tool that we've developed this year called the Coil Design Assistant. That's our CDA. I believe you guys did a little feature on it not that long ago, but that is a feature where customers can go on our website and essentially find a variety of different coil types and they can put in what dimensions they think they want or need and then we get an email and we can essentially do an approval drawing and a quote for them right there off of the web.

DG: Basically, it's a web tool to help you design a coil.

Doug Glenn, Heat Treat Today publisher and Heat Treat Radio host.

To hear this episode and other Heat Treat Radio podcasts, please check out heattreattoday.com/media/heat-treat-radio