Welcome to another episode of Heat Treat Radio, a periodic podcast where Heat Treat Radio host, Doug Glenn, discusses cutting-edge topics with industry-leading personalities. Below, you can either listen to the podcast by clicking on the audio play button, or you can read an edited version of the transcript. To see a complete list of other Heat Treat Radio episodes, click here.

Welcome to another episode of Heat Treat Radio, a periodic podcast where Heat Treat Radio host, Doug Glenn, discusses cutting-edge topics with industry-leading personalities. Below, you can either listen to the podcast by clicking on the audio play button, or you can read an edited version of the transcript. To see a complete list of other Heat Treat Radio episodes, click here.

Audio: James Jan & Andrew Martin on Development of Modeling Software

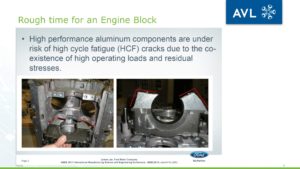

In this conversation, Heat Treat Radio host, Doug Glenn, publisher of Heat Treat Today, interviews Ford Motor Company’s James Jan about Ford’s cooperation with AVL on the development of modeling software to help predict and avoid cracking on aluminum cylinder heads. Andrew Martin from AVL also joins the conversation with what exactly it is they did with Ford.

Click the play button below to listen.

Transcript: James Jan & Andrew Martin on Development of Modeling Software

The following transcript has been edited for your reading enjoyment.

Mr. James Jan, Ford Motor Company (JJ): My name is James Jan. I graduated from the University of Michigan in Ann Arbor, and I have a Ph.D. in mechanical engineering and during my Ph.D. studies, I focused on multiphase flow. Basically it is the full mechanics but we deal with multiple phases—usually it is a mixture of liquid and gas. I graduated in 1994 and I’ve been working with industry, the automotive industry, to be more specific, since my graduation. I have worked in the auto industry for 20+ years, since 1994. However, I’ve been involved in quite a few different subjects in my career even though they are all sensor or fluid mechanics, spent three years writing software (which is also a CFD software), and I work on the intake exhaust manifold and work on the local problems. I was pulled into Ford for this current project back in 2011. That was the time I got very heavily involved in the development of the heat treat process. Before that CFD, but after that it’s about heat treat.

Doug Glenn, Heat Treat Radio (DG): As Mr. Jan says, he is now heavily involved with heat treat, specifically on modeling of the quenching process for aluminum cylinder heads. I asked Mr. Jan to explain the issue that Ford was having. But before he describes the situation, it is important for you to know that Ford was addressing this issue long before nearly all other car manufacturers and is, in fact, a leader in industry with regard to resolving this highly technical heat treat and product design situation. Here is how Mr. Jan describes the situation that set the ball rolling nearly 20 years ago at Ford.

JJ: The reason that they wanted to solve the problem is because during the heat treat process there are a lot of cracks. The cracking problem during heat treating has been a quality concern for Ford for many, many years. I would say that the problem has been there for 20 some years. In the past, during the cracking process, one of the remedies would be to do a lot of trial and error. For example, during water quench if they see a crack, they switch to air, and if the air doesn’t work, then they switch to polymer. Or if this is cracking somewhere or in some location, they add more material in that area. So, it’s pretty much like responding to the problem, rather than trying to understand the problem and to predict the problem. So that is where the whole thing comes in that the researchers started the project in 2002 because they believe that they really needed a tool to predict the problem rather than responding to it.

DG: So, the problem Ford was having was decades old. And it is a problem that many manufacturers have. It is the age-old problem of being able to predict residual stresses formed during the quenching process that ultimately result in cracking and component failures. Ford, like many other manufacturers, were simply doing trial and error until they got the right combination of part geography, heat treat cycle, and quenching medium and quench orientation. The problem is, that process takes a long, long time and it costs a huge amount of money. Here is Mr. Jan describing the issue with a trial and error approach.

JJ: Every time they make a change to a design, they have to build a prototype part. There will be cost involved because when you build the prototype, you still need a die, you still need the testing process, and then once you have built it you have to run the test to see if it cracks or not. This back and forth just simply takes too much time and too much cost.

DG: The thinking was that if the design engineer and manufacturing engineer could talk earlier in the process, it would help save time and money. Specifically, it would be better if the design engineer could interact with some sort of predictive modeling system that fairly accurately represented the heat treating and quenching portion of the manufacturing process to predict residual stresses and potential cracking issues before they happened. If that were possible, it would save Ford thousands if not hundreds of thousands of dollars. Here is Mr. Jan describing the idea.

JJ: This has something to do with the product development process. When any company tries to development product, their first objective is to satisfy the functional requirement. So basically, if you have an engine and you want a certain horsepower, you want to make sure your engine will satisfy the horsepower. At the beginning of design, their only concern is about functionality, they don’t care about anything else. Once the design is fixed, somebody needs to make it. I belong to manufacturing engineering, so we do not deal with designing, we deal with how to make that part.

During the design process, they usually do not have manufacturing information. Once the design is done, which is usually pretty late in the design cycle, the part has pretty much been determined already. Then we come to manufacturing and we try to quench it, and find, “Oh, gee, it’s cracked.” Then we tell product development, “We have a cracking problem,” and they say, “I wish you had told me earlier.” That is where the problem comes in. Because we are not able to know if the process works or not until we have a physical part, so that’s why Ford’s research tried to initiate a project that said even though design is still ongoing and the manufacturing generally has not started yet, let’s try to do some virtual process simulations to see whether it will crack or not.

DG: The specific tool that Ford was looking for was a tool that could predict multiphase flow quenching outcomes, what many of our listeners would recognize as the Leidenfrost Effect or vapor boiling. According to Mr. Jan:

DG: The specific tool that Ford was looking for was a tool that could predict multiphase flow quenching outcomes, what many of our listeners would recognize as the Leidenfrost Effect or vapor boiling. According to Mr. Jan:

JJ: The boiling process, because the physics is very complicated, we couldn’t find any commercial software on the market that would solve the problem. So, we contacted AVL at the time.

DG: As Mr. Jan said, since they weren’t able to find any commercially available software to predict the multiphase Leidenfrost Effect, they turned to AVL. So, Heat Treat Radio put a call into AVL Powertrain Engineering in Plymouth, Michigan, and spoke with Andrew Martin, who is the direct of advanced simulation technologies. We asked him about AVL’s relationship with Ford.

Andrew Martin, AVL (AM): Our relationship has gone back to about 20 years now. Twenty years ago, Ford was seeing cracking in the cylinder heads—and not only Ford but many of its competitors out in the marketplace. So, this was something they wanted to explore. AVL as a company, currently at about 10,000 engineers, has always had a strong relationship with Ford. We develop engines and transmissions together, and things like that. Ford came to us and asked can you look into this? They knew that we had a good CFD code and we were doing a lot of multiphase work, especially on things like fuel injection and boiling in water jackets and things like that. They knew we had a reputation in those areas, so they wanted to work with us on coming up with some sort of a simulation and analysis approach for the boiling that occurs during quenching analysis. Between us, we did the research and that led to a technical paper that was published, I think ASME, but that was in 2002. James (Jan) was involved in that paper back then as well.

DG: I asked Andrew to briefly describe the cylinder head issue that Ford brought to them.

AM: Cylinder heads are very complicated because they have so many cavities. When you quench something like that, then the vapor gets trapped in certain areas and that can lead then to localized residual stresses.

DG: And what did AVL have to bring to the table?

AM: Previously, they were doing it the old-fashioned way, they were doing with thermocouples. They would thermocouple a cylinder head and quench it and then look at the data and get the HTCs (heat transfer coefficients) from it then feed that back into the CFD code and then make some assessments about the residual stresses and the distortion. But that is a very expensive way of doing it and it doesn’t lend itself very well as a designing tool. They wanted to find some mathematical approach for doing that. James is extremely experienced in CFD and has used a whole bunch of our CFD codes that compete with AVL FIRE. But he then started using FIRE and realizing that given all the tools that he had at his disposal, FIRE was the one that was giving the best results for doing this boiling analysis.

DG: Andrew referred to AVL FIRE which is a brand name of a specific product offered by AVL. I asked him to briefly explain that product.

AM: AVL FIRE is a CFD (computational fluid dynamics) code. It is an engineering discipline that is quite common and quite popular. We then used CFD to model the boiling that goes within a tank of water and the interface between the component and the water, the so-called film boiling barrier. We model what happens with FIRE CFD code, we model what is happening at the transition of the interface between the metal component and the water. Because when something that hot gets plunged into water, it is quite an interesting thing that happens—it is called the Leidenfrost Effect. Initially, what happens is the component is so hot, it forms a film around the outside of it, a vapor film, and perversely that vapor film then insulates the component from the water. That film slowly breaks down then you get into nucleate boiling and things like that, and that becomes a lot more aggressive and the cooling happens much faster until you eventually get a single phase. But actually modeling the boiling process is what the CFD code does. That is the secret sauce that we’re bringing to the party here.

DG: And, in fact, this secret sauce that Andrew refers to is quite unique. Earlier, James Jan from Ford mentioned that the AVL model was able to handle multiphase analysis, where most other models simply ignored one of the phases, usually gas, and focused exclusively on the interaction between the hot metal and water. I asked Andrew to unpack this more sophisticated modeling process and what developments have been made since they initially started working with Ford.

AM: Since then, it’s matured a lot further within the software. We now have different meshing approaches and we’ve also moved beyond water as well, of course. A lot of quenching is done in water, but there is also a lot of gas quenching, so blown air quenching, which takes longer but is less aggressive. And then we’ve got into steels as well. The original work we did with James was more on aluminum and that doesn’t have the same phase transformation issues as steel does. So

we’ve done a lot more work with steel recently, where we have to take account of that latent heat, that then forms a sort of a knee in the cooling, so we then model that. When we doing steel, of course, we’re using oil more commonly, so then we have different properties of oil to consider, different fluid properties of that. Most recently and what has been very interesting, we’ve been involved with a Canadian casting company on spray quenching. There you have a mix

between blown air and actually liquid itself where we’re spraying a jet of fluid at the component. Mathematically, that is a heck of a lot more complicated because you have to model the spray and you have to model the Ledienfrost Effect and the cooling and so on.

DG: Given the solution that AVL brought to Ford, I was curious if both Ford and both AVL were happy with the partnership. First, James Jan from Ford on how Ford and AVL worked together to develop the tool.

JJ: As a matter of fact, even though AVL worked with us to provide us the technology, it is not like we just go buy it and use it.

Actually, we worked together about 3 to 4 years. On our end, we provided a lot of testing data because we work with a university and we also have an experiment facility inside Ford. When they provided the tool to us, it is still like a banana. They have the basic formulation working but they haven’t tested or validated, so there are 3 to 4 years where we were actually working like partners. It is not like, ok, I’m going to Home Depot, buy a tool and come home and use it. No. We actually did not put the AVL tool into production use until 2015. So there was about 3 to 4 years of time going back and forth trying to improve software. Until today, we still own a small piece of the technology, that is proprietary to our company Ford. Even though to AVL and buy their software and they bring it home, they may not produce the same results that we do, because we have a secret recipe in Ford.

AM: We’ve been very happy with the willingness of Ford to develop the process further, to mature it. They saw that we had something that was useful and beneficial and brought value, but actually James has been phenomenal, because he’s really pushed that agenda as well, and written papers and taken it to conferences, and I think he’s been very impressed with what AVL FIRE has been able to do, so he will talk to anybody about it. So we love it.

DG: Finally, I asked Andrew Martin from AVL who, in his estimation, would also benefit from the AVL fire and similar products, and what changes are being made for the future.

AM: It’s casting companies for sure. I was talking to a British company that makes castings, like high-end blocks for Astin Martins and Land Rovers and so on, and they have certain specifications they have to meet. They are not allowed to have a residual stress more than a certain level in a certain direction. Now how do they know that that’s the case? They can actually cast a few and then heat treat them and then cut them up and see how the material releases, but that rather destroys the actual component in the first place. So companies like that that want to know where are the residual stresses in the component and they want that as something that they can certify the component for, it is very good for that sort of company. Automotive is an obvious candidate, but also we’ve been doing a lot more work in aerospace where the residual stresses that they do want to know where are they and how much are they. Things like landing gears and stuff like that.

DG: And how about the future?

AM: Well, our software is developed over in Europe. I talked to Dr. David Greif the product manager the other day asking him where are we going with this. We’re making it a lot more easy to use. We’re putting workflows in place in AVL FIRE that sort of lead the user through the steps needed to predict the residual stresses and so on. The meshing of the components got a lot simpler using this polymeshing and it more leads you by the hand, as opposed to being a general purpose CFD code where you’ve got to build your own methodology to start off with. FIRE has a methodology built in for doing quenching and that’s brilliant. We’re doing a lot of work with gears at the moment. We’re working with a vacuum furnace company in Wisconsin called ECM Group and they’ve been using AVL FIRE for predicting the residual stresses in the components, so we’ve got a great relationship with ECM and that’s taking us in different directions as well. They are especially doing work on the gear side, so that’s been interesting.

DG: In fact, the whole relationship between Ford and AVL is interesting, as well as the ability to bridge the gap between design and heat treatment. Specifically, the quenching part of heat treatment. With advances in technology and modeling packages like AVL’s FIRE, high volume producers like Ford and other automotive, as well as aerospace manufacturers, have the opportunity to save significant dollars by modeling the process before they jump into the manufacturing process with both feet.

This interview is a follow up to an article in Heat Treat Pro, a publication of ASM International, “Using Virtual Tools for Quenching Process Design” by James Jan and Madhusudhan Nannapuraju. Images from powerpoint presentation and provided by AVL.

To find other Heat Treat Radio episodes, go to www.heattreattoday.com/radio and look in the list of Heat Treat Radio episodes listed.