Heat Treat Radio host Doug Glenn talks with Joe Powell of Integrated Heat Treating Solutions in this third of a four episode series about bringing heat treating into the 21st century. This episode covers the fascinating heat treatment of a fracking pump valve seat.

Heat Treat Radio host Doug Glenn talks with Joe Powell of Integrated Heat Treating Solutions in this third of a four episode series about bringing heat treating into the 21st century. This episode covers the fascinating heat treatment of a fracking pump valve seat.

Below, you can either listen to the podcast by clicking on the audio play button, or you can read an edited version of the transcript.

The following transcript has been edited for your reading enjoyment.

Doug Glenn (DG): We're continuing our conversation with Joe Powell of Integrated Heat Treating Solutions. on rethinking heat treating. I strongly recommend that you listen to parts 1 and 2 of this series as well as today's episode. All three are fascinating. To hear the first two parts, click here.

Today, we’ll be talking about what I think, if you've listened to the first two episodes of this four part series, is a very fascinating, I think, somewhat revolutionary advancement in heat treat.

Today, basically what we want to talk about is a really interesting example of the general concept of what we talked about in session one. I want to review that first session very briefly and ask you a couple of other quick questions before we jump into the example of a fracking pump valve seat, which is where we're headed today. But first, maybe from a 30,000-foot view, Joe, tell us what we're talking about here. If you were to put this in a minute, how would you describe what it is you've been doing over at Integrated Heat Treating Solutions?

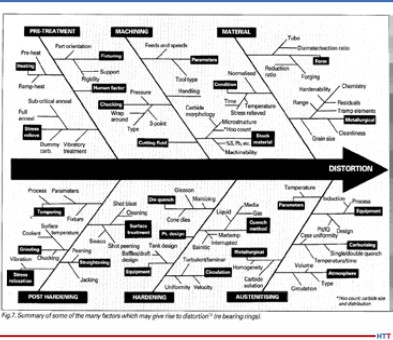

Joe Powell (JP): Integrated Heat Treating Solutions (IHTS) is a consultancy that takes 75 years of practical commercial heat treating and applies it to help part-makers make better parts by using heat treating knowledge. We also work with the material-makers who want to get more added value out of a given hardenability material. What IHTS is essentially doing is taking off from the idea that quenching causes the most problems in heating: it causes distortion, part cracking and size change that is unpredictable. That distortion engineering has been part of the ASM and other societies that have had task forces, committees, and various conferences that are dedicated to the control of distortion.

(Source: American Gear Manufacturers Association, sourced by Joe Powell)

The reality is that the control of distortion has been approached by many, many people, including Dr. George Tautin, who was one of the inventors of the reverse solubility polymers when he worked for Dow Chemical and Union Carbide, and Dr. Kovosko in the former Soviet Union, who was my partner in IQ Technologies starting back in 1999. What we've discovered working with all of these very smart people is that the quench cooling rate and its relationship to causing part distortion or part cracking is a bell shape curve. In other words, if you quench very slowly in air or gas or hot oil or martemper salts, hot salts for austempering, you will not crack the part. But, if you quench faster in brine, water, or even water polymer mixtures that don't have enough polymer in them to act like an oil quench, the cooling rate will become relatively fast. That relatively fast cooling rate will give you a much higher probability of part cracking, until on some parts you'll literally crack every part you put in the quench if it's quenched in water.

If you can create a shell on the outside of the part and quench it 752°-1112° F (400°- 600° C) per second, that shell will literally hold that hot part while the hot core thermally shrinks underneath and pulls that shell under compression. As that thermally cooling shell and hardened shell of martensite goes through volume change and actually increases in volume, the grains are actually pushed up against each other under compressive surface stresses, and that compressive surface stress holds the part like a die. So, regardless of its geometry or mass, that part is going to come out of the quench having cooled by uniform conduction down to its core through that shell in a very predictable shape.

DG: That's exactly what I wanted to get to: what we're talking about here is a quenching issue. It's quenching parts fast enough so that, in a sense, what you're doing is creating a hard outer, immovable shell, if you will, pretty much instantaneously, which holds that part in place while the core cools down to the temperature that is needed.

The quenching media, in one sense, don't really matter. It can be done. The issue is getting that shell formed quickly, uniformly and then holding it at a certain temperature until the core cools.

You and I have spoken in the past, Joe, about a kind of interesting quote which I'd like you to comment on before we get to the fracking pump valve seat example of what we're talking about. Here’s the quote I'd like you to address, “Everyone knows how to heat treat. All you need is a torch and a bucket of water.”

"Every day I learn that in the 23 years that I've been working on heat treat quenching and focusing on that and controlling of distortion, there is always something new, and there is always something new in the field of, what I call, metallophysics."

JP: That's correct. Every machinist you'll ever meet, and even a machining handbook, will tell you how to heat treat a part, and do it quick and dirty. The problem is everybody thinks that it’s because they've heat treated a part in the past, that they know a lot about heat treating, and that is just not the case. There is so much to know, that all I can tell you is that every day I learn something new. Every day I learn that in the 23 years that I've been working on heat treat quenching and focusing on that and controlling of distortion, there is always something new, and there is always something new in the field of, what I call, metallophysics.

DG: Right. It brings me back to a couple of thoughts along that line. One, it's the whole idea that “a little knowledge is a dangerous thing” – we think we know and yet, we don't. You've told me a story in the past and I think it's worth our listeners hearing it, and that is just an abbreviated version of the Jack Wallace story. Again, Jack Wallace, the head heat treat metallurgical guru at Case Western Reserve University, comes into your shop and you tell him, “I can quench these things so super-fast,” and he looks at you and says, “You are a crazy man. It's not possible.”

JP: Actually, it was worse than that. Dr. Michael Aerinoff came from Russia and was telling Jack about this technology that Dr. Kovosko discovered back in the former Soviet Union. So, it had two strikes against it. Not only was it new information and contrary to the idea that the faster you quench, the more likely you are to blow up the part, but it was also contrary to the information, “Hey, we're in the United States. We know all about heat treating and metallurgy!” At the end of the day, this metallophysics twist that Dr. Kovosko put on the dynamics of the heating and cooling process is really the key to understanding and viewing metallurgy from another dimension – the dimension of residual and current compressive stresses that are affecting the part. That's what Dr. Kovosko told us about, and finally, that's what unlocked the ability of the parts that Professor Wallace witnessed being quenched and not cracking.

DG: I would have loved to have been there and seen the eyebrows of Dr. Wallace.

JP: The other two metallurgists who were in the room besides me – two owners of heat treating companies, Wayne Samuelson of Shore Metal Treating at that time and John Vanas at Euclid Heat Treating – both of them basically wrote Michael off as a crackpot because they had heard what professor Wallace had said. I was the only one dumb enough to think, “Well, come on down. If you want to demonstrate some parts, they're either going to blow up or they're not. If they don't blow up, it'll be interesting, and if they do blow up, it will be funny, so let's try it!”

DG I wanted our listeners to hear some of the other people who are now, as I say in quotes “true believers.” You've got Jack Wallace who now believes what you say is actually true. You've also got, I believe, George Tautin, who is kind of the “king of quench.”

JP: Absolutely. He's actually written a book with us. It's an ASTM book; it's publication #64, I believe, and that book tells you exactly how to build the first and second generations of IQ (intensive quenching) equipment. George also said in 2014, after he retired from making polymer quenches, that you don't really need oils or polymer quenches. You can do quenching very nicely with a properly designed quenching system and water, or water and a little bit of salt. That was a pretty strong statement from a guy who literally spent his career making those quenches better.

DG: You had mentioned one other individual, Robert O'Rourke.

JP: Yes, he is a metallurgist with over 30 years of experience with ductile iron. Bob worked with one of the industry giants, Chip Keough,* who founded Applied Process and also austempered ductile iron. Chip's company not only worked with the ductile iron society for many years, but also with Bob O'Rourke, who was one of the principals at the Ductile Iron Society; in fact, he was president back in 2015. At the end of the day, he basically said that we could take this kind of crappy material, ductile iron, and austemper it. Chip made a very good business out of austempering ductile iron at Applied Process and converted many, many parts from either as-cast ductile or even steel parts to austempered ductile iron parts.

That, to me, showed that it's possible to take a heat treating process and apply it to a material and literally create a new material out of as-cast ductile irons. Chip even said, “I know what you guys are doing. When we quench in salt, it's very uniform. There is no film boiling. There is no nonuniformity in the cooling. All you're doing is just kicking it up a notch with higher intensity and knocking off the film boiling with the intensive agitation.” And I said, “You're absolutely right, Chip.” What we did not know at that time was that it could be applied to ductile iron.

DG: Let's jump into this fracking pump valve seat. A couple basic questions. First off, we're talking about a pump that is used in the fracking industry to extract out, I assume, the fracking fluids, and things of that sort.

JP: It's actually to inject the high-pressure water sand. They call the sand a proppant. After the pump has fractured the shale layers, then they inject water and sand to hold up and prop up those cracks in the geology and allow the gas to flow out more quickly.

DG: Good. So, the point is, it is very rugged and the pump takes a beating. What was the problem that the company was having? How did it come to your attention?

JP: The frackers were having to rebuild the pumps every 40-60 hours and replace these valve seats. They had high pressure water and sand flowing through the valves. The valve would open and close under pressure at about four times a second, and that constant abrasion of the valve opening and closing and banging into the seat was causing the seat to wear out. Once the seat is worn, then the pump can't maintain its pressure, and they're not getting anywhere in terms of putting that fluid down in that well, and therefore, making it produce more oil and gas products.

DG: Essentially, you've got fracking companies who are having to replace valve seats and rebuild the valves every 40-60 hours. What was the material that was being used for the valve seat?

JP: For years, these types of seats were made of 8620 carburized steel. They usually start with a forged ring, and then they machine that ring into a valve seat with a taper and a strike face where the valve closes onto the valve seat. That part is generally carburized around 90,000th of an inch effective case step and tempered and then put into the pumps. Again, that case hardened surface is 60–65 Rockwell and wears very, very well and resists the abrasion of the sand and water. Because it's 8620, it has a ductile core underneath the strike face that absorbs the impact of the valve opening and closing on top of it every four seconds under pressure.

You have to have a combination of hard, yet ductile. And you have to have a tough part that resists wear and abrasion.

DG: These guys were using it and still having to replace it every 40-60 hours, so what was your thinking on it and how did you guys help?

JP: A whole bunch of people had tried to put tungsten carbide inserts into the strike face to make the strike face even harder than case hardened material. Then a company came out with a solid sintered tungsten carbide valve seat that costs upward of $500–800 each. You’ve got to remember that there are ten of them in the pump, and they were built as a lifetime valve seat because they actually outlasted the pump block and some of the other parts of the pump. But that was not a great solution because, at that point, you have a seat that's lasting longer than the pump block. You still had to take apart the pump anyway for other things that were worn; it's too good and it's too expensive. If you've got $8,000 worth of seats, you're not going to throw the pump block out because it's worn out, you're going to try to remove those seats.

(Source: Joe Powell)

Again, what they were looking for was a longer life valve seat, not necessarily a lifetime valve seat, but something that would last for all of the stages used by that pump at a certain well. They would move it at the time that the well completely fracked and started to produce and take it back and rebuild it at their shop. They were shooting for 200 hours.

DG: Right. Again, the normal was 40-60 hours with the 8620 material.

JP: Right. Having had the experience with the elongator roll and the ability to make something that was literally so hard they couldn't knurl it, we had to temper those elongator rolls back quite a bit in order for them to knurl them and then use them at the mill. I thought, if we don't temper the valve seat back and just leave it that hard, it should be carbide-like hard, because if a carbide tool can't knurl it, it's pretty doggone hard. We fired up our existing piece of equipment that we had at Akron Steel Treating, a 6,000-gallon intensive quenching tank. We heated the parts and quenched them in that big batch tank, and we got very nonuniform results.

One of the things we did not understand back in 2012 was that ductile iron, because of all the graphite particles that are in there, has a very low thermal diffusivity, meaning that in order to get the heat into it or out of it during the quench, you had to be more than intensive; you had to be, what I call, instantaneously impacting that surface with high pressure water that literally pulls the heat out at a rate that will allow you to get to the martensite start temperature, cool to the martensite start temperature, and form that shell in less than 2/10th of a second – and you have to do that all over the part surface to create that shell. This required the making of some new induction heating equipment that have an integrated quench system built into it. This integrated quench system is going way past the ability of our 6,000-gallon tank with its propellers flowing the water laminally across the surface and literally impacting the part instantaneously after the induction heat is turned off.

DG: I want to mention to the listeners that we'll put a photo of this part in the transcript that we'll have on the website so that they can get a much better sense of what the part is; there are some lips and turns and there is an inside diameter and an outside diameter. As you say, if you're flowing water laminally over this, you're going to be missing parts and you're going to be missing areas of the part, so you need to get it quenched quickly.

JP: They actually did crack in the O-ring groove and under the flange out of our 6,000-gallon tank, so we knew we had to do something different. The first thing we tried was to put in the flange and the O-ring groove after it was heat treated, but that wasn't going to work because the part-maker didn't want to have to machine it twice. We had to come up with a way of delivering that water all over the shell of that part and also keeping the core relatively ductile. We didn't want to harden it all the way through and make it brittle, so that's what we came up with while working with the folks at Induction Tooling in North Royalton.

DG: So, it was basically an induction heat and an integral induction quench, very high impact, instantaneous, probably way beyond what anybody else has seen. Describe very briefly, what kind of horsepower was needed to go into the quench.

JP: We used a 60 gallon/minute pump for the ID and a 60 gallon/minute pump on the OD. Both pumps were operating at 60 psi, so there is quite a bit of pressure and quite a bit of flow over a very, very small area.

DG: Which is exactly what needed to be done. So, talk about the results. You're hinting at them here, but what are we talking about in regards to Rockwell hardness and that type of stuff?

JP: We're getting 60+ Rockwell hardness. Again, you've got to remember that this is an apparent hardness because the Rockwell machine is fooled by the very soft graphite particles that are in the matrix. You have very, very hard martensitic iron and carbon in the surface, but you also have these little particles of spherical graphite, and that graphite acts as, what we believe, a lubricant. We haven't quantified it in the valve seat, but we've quantified it for some dies that gives lubricity that's not present in a steel part. The graphite lubricates whatever is traveling over the surface of the part. The other thing that we learned is that the compressive residual surface stresses, when tested by x-ray defraction, are about double that you get when you do carburization of the 8620 valve seat. The very high residual compressive surface stresses also hold those grains of iron carbides in place and does not allow them to abrade or erode. In the first testing, we had three seats that went out to the field somewhere in west Texas, and they lasted 166 hours. We were almost there.

So, we've modified the quenching system, we've modified our heating recipe on the induction tooling, and we made another set of valve seats which we are currently sending out for more field testing. We hope we're there and we'll see what happens. But we literally created a new material. The history of ductile iron goes from as-cast to austempered ductile iron and now, what we call, instantly quenched ductile iron or IQDI

DG: Nice. It all sounds very, very interesting, but I can see some people listening to this saying, “Ok, how much is this going to save me?” Let's talk about the ways that this process saves money. In my mind, you've got a shorter processing cycle time, you're using less expensive material, and you're getting a longer life. Are those the three major ones?

"With the valve seat, the forging and the 20 hour carburizing cycle are eliminated, and it’s machined three times faster. One customer let slip that they were saving about 66% on the material cost."

JP: There is also one other and that is ductile iron because those graphite particles machines about three times faster than steel. So your through-put in your CNC machine goes up by 2 or 3 times when you're making the part and that is no small matter. Also, because the quench is so impactful and so uniformly impactful, it sets the part and you literally get a part that quenches to fit. Once the green size before heat treating is adjusted, the part may not need much, or if any, final grinding.

DG: So, you're saving on post heat treat processing, as well.

JP: Right. And, because we use no oil, we don't have to wash the parts and we don't have to worry about disposing of quench oils or about quench oil fires. And, the process can be done in the machining cell, so it's an in-line process versus a batch carburizing process that has to go someplace for 20 hours to be carburized.

DG: Significant. I think you threw out a dollar figure when we spoke about this previously. What are the savings per valve seat?

JP: With the valve seat, the forging and the 20 hour carburizing cycle are eliminated, and it’s machined three times faster. One customer let slip that they were saving about 66% on the material cost.

DG: Wow. Significant cost savings is the point, so something worth looking into. We're going to have one more episode where we talk about another example. What do you think we'll talk about in the last episode?

JP: The integration of heat treating into the forging process.

DG: Alright super. Thanks for being with us, Joe. It’s always interesting and intriguing.

JP: The integration of heat treating into the forging process. The forging industry association sponsored a project with IQ Technologies. Akron Steel Treating is a member of the forging industry technical committee and has been for years, and we've always thought that there should be a closer alliance between forgers and their heat treaters. We're going to take the information that we gained from this 4 year project, the published final report will be on our website, and we're going to try to commercialize that for a lot of different parts.

*John (Chip) Keough is the son of W. R. Keough, founder of Applied Process (1962).

To find other Heat Treat Radio episodes, go to www.heattreattoday.com/radio and look in the list of Heat Treat Radio episodes listed.