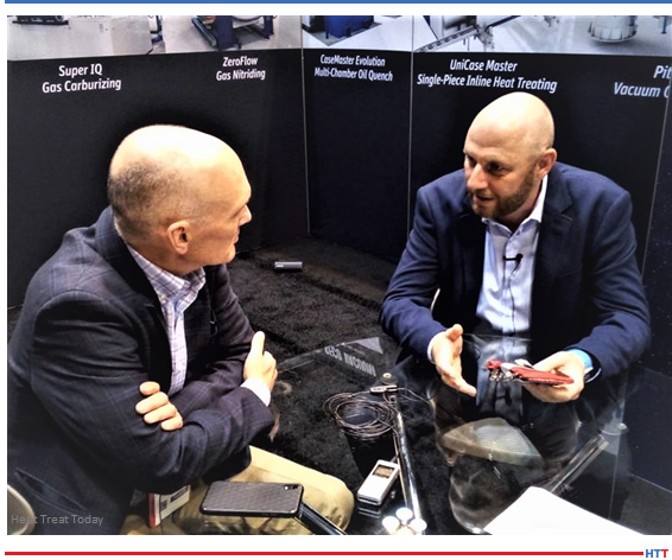

Heat Treat Today publisher, Doug Glenn, sat down with heat treating specialist, Piotr Zawistowski, the managing director at SECO/VACUUM, to hear what he believes the future of heat treat holds. Karen Gantzer and Bethany Leone from Heat Treat Today also joined the conversation, recorded at the ASM Heat Treat Show 2021. In this episode, you’ll learn why Piotr believes LPC, automation, and predictive maintenance are the future of heat treat and how to get there.

Heat Treat Today publisher, Doug Glenn, sat down with heat treating specialist, Piotr Zawistowski, the managing director at SECO/VACUUM, to hear what he believes the future of heat treat holds. Karen Gantzer and Bethany Leone from Heat Treat Today also joined the conversation, recorded at the ASM Heat Treat Show 2021. In this episode, you’ll learn why Piotr believes LPC, automation, and predictive maintenance are the future of heat treat and how to get there.

Below, you can watch the video, listen to the podcast by clicking on the audio play button, or read an edited transcript.

The following transcript has been edited for your reading enjoyment.

Bethany Leone (BL): Peter first shared how SECO/WARWICK was on a mission to actualize the future of heat treat.

Piotr Zawistowski (PZ): I think we are on a mission, that is, SECO/WARWICK and I. I think the future of heat treatment will be LPC for carburizing, and gas quenching for quenching instead of oil. I think the future is LPC and hydrogen quenching, to be honest. Right now, most of carburizing is done in a carburizing atmosphere, and most of the quenching, as I know it. I think that everything is moving in the vacuum direction, if you will, but we're not there yet. So, that's our mission, in general.

I think I showed you a graph with what is the difference in quenching between oil and gas. Right now, with 25 bar quenching, we are on the level of slow oil. To get there, we have to use helium, but it's expensive, it's not economical. We can go to hydrogen, which is the speed of oil and it's everywhere, it's cheap. I think this is the future.

BL: This idea that the future of heat treat will be LPC and gas quenching – specifically with hydrogen – means moving in the vacuum direction, as Peter noted. But how fast will this transition come, especially given safety concerns with the use of hydrogen as a quenchant?

PZ: Exactly, that is the concern right now. I think it will come, but we are far away from it. Anyway, we don't have to go to hydrogen immediately, but I think we should go to nitrogen for now. We have some solutions for that, and on top of that, I think we will go from regular carburizing to LPC. It's not easy for people to switch, so our mission is for us to try to convince people to switch to LPC. We would like to make it as easy as possible for them so that's why—maybe 20 years ago—we thought about starting. Because we had quenching and carburizing, we thought, let's maybe leave quenching the same and start with carburizing. So, we developed vacuum oil quench furnaces just to make it easier so they only have to change one thing at a time. But then, we thought, it's a leap for them anyway because those are different oils and it's a vacuum oil. So, right now, we're introducing a furnace with vacuum carburizing with the regular atmosphere is a quenching chamber in regular oils that all the heat treaters have known for years.

DG: This is the SuperIQ?

PZ: This is the SuperIQ. I don't want to make it commercial, but this is another step. If you look at our wall here, we have six different products and five of them are for carburizing. It starts with Vector. It can have carburizing but it doesn't have to be, but anyway, they all are connected with carburizing. I think the mission is to convince people and to switch, in the industry, from all the messy dangerous, open-fire furnaces to new, clean, better technology.

BL: As we just heard, these are big transitions. So, if the first step towards heat treat with LPC is for heat treaters to use atmosphere carburizing with oil quench, what are the next steps to move to a fully vacuum-based future?

PZ: Step number two is vacuum oil quench and step number three is vacuum carburizing or LPC and high pressure gas quench. That is the future, in my opinion, and with hydrogen.

BL: As a review, moving to LPC could look like, first, using a traditional vacuum furnace with atmosphere capabilities, then, heat treating with vacuum oil quench, and finally, heat treating with LPC and high pressure gas quench. If such a transition is appealing, it would be good know what the productivity improvements of LPC are. . .

PZ: So, it depends; there are a couple factors. First, we have to take into account what kind of a case that we're talking about. But, in general, I can tell you that the productivity increase should be 50%, or even 100%, or more.

DG: You can double the amount of product through in the same amount of time?

PZ: Yes. And, it's just as simple with increasing the temperature, so we are not limited with low pressure carburizing with the temperature, whereas there is a limit that atmosphere carburizing can be done. So, we have a lot of possibilities here.

BL: So, a 50-100% increase in productivity and an increased temperature range comes along with low pressure carburizing, LPC. When considering LPC, there is the question of how traditional specification, which clearly state the necessity of atmosphere carburizing, can be compatible with this newer technology.

PZ: Yes, and those specs are changing.

DG: Is that going to be a hindrance?

PZ: Yes, it is right now, especially in aerospace. The automotive industry, they moved already to LPC, but aerospace we are trying to help to change those specs, and they are changing as we speak. A lot of those specs are still from the '80s, and there was no LPC back then. As you know, in aerospace, it is not easy to change a spec, but this is happening right now, as we speak.

DG: Are you guys involved with changes from Nadcap and all?

PZ: Yes, and we are involved in major aerospace players. We are doing tests for them and we are delivering them LPC furnaces. Some of them are still doing R&D, but this is a first step. With some of them, we are starting to see real production with LPC in aerospace, so we are getting there.

BL: To be sure, integrating the technical creation of specs by bringing heat treaters in touch with key end-users in the industry is necessary to have standards reflect effective heat treating techniques. Aside from standards, is there any resistance to adopting low pressure carburizing?

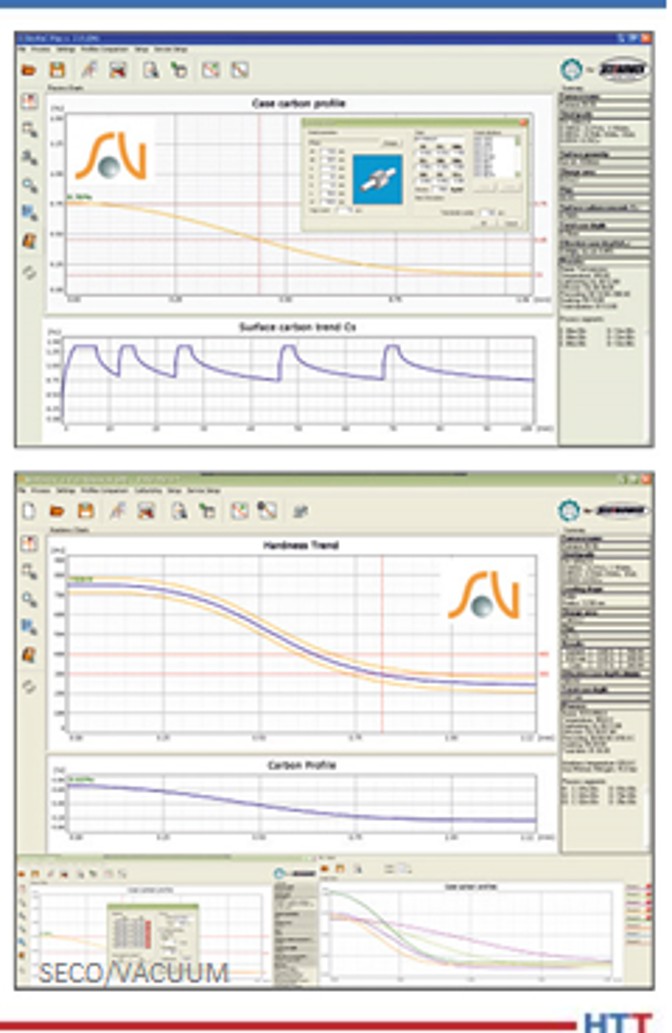

PZ: I think, people are afraid of what is new: atmospheric carburizing is very simple and it is well known, vacuum carburizing is something different. So, for atmosphere carburizing, it's only to control the potential in the furnace and time of carburizing. In vacuum carburizing, it's not that easy- you have to have a special simulator to create a recipe. People are afraid of it, but they shouldn't be because there is software. We have software that can make that recipe really easy and pretty quick. People are just afraid of something new.

We have it [simulator] to create a recipe for LPC for the purpose of carburizing and we actually provide it. This is our own simulator and we provide it with the equipment so it's very, very easy.

BL: In addition to an aversion to the new and the changes that may be involved, folks have a real concern with distortion. Peter then addressed this concern. . .

PZ: High pressure gas quenching, in general, is better, but there are other methods. It is not only us, but we are all trying to limit the distortions; we cannot say “eliminate” because that is impossible, but we can try to limit the distortion and control the distortions. What we introduced to the market is our 4D quench technology, “fourth” dimension is that we rotate the part during quenching.

BL: While there is resistance that may be from outdated industry specs, a suspicion of the new, or technical concerns which the industry is continually addressing, Peter was sure note that there are, in fact, drivers that are encouraging heat treaters to move towards LPC.

PZ: I think, the driver is both productivity and safety. As an example, the [US] Biden administration just committed to reduce CO2 emission by 50% by the end of the decade. This is good technology and there is a lot of fuel to emission out of atmosphere carburizing, internal and external. But, there will be a push for climate change and CO2 emission. I think, it's not only mandates, but, I think, in Europe, for example, they have a lot of grant; there is a lot of government money you can get if you are reducing the CO2 emission. I think, for the heat treaters, it should be easy to capitalize on it. As I said, no CO2 emission on LPC. There is no emission at all. That is the beauty of the technology.

BL: Certainly, financial incentives to adopt “greener” technologies as well as personal desire to do so would be motivating. Is there anything about the heat treated parts cosmetically that would make LPC attractive?

PZ: Of course. And, you don't have to wash it after, which is great. It depends, as we still can have LPC and oil quench, you have to wash it, but if you can get to the gas quench, you've eliminated the wash part. They just look nice and shiny and bright. The color is better and you can eliminate washing.

BL: It is clear that LPC, one of the factors that plays into the future of heat treat as Peter envisions, has challenges and benefits for heat treaters to consider. Peter then talked about two additional factors for the future of heat treat: automation and predictive maintenance.

PZ: There are two other factors. One is automation, which is something big and it's more and more especially nowadays with the labor issue. But, it is to eliminate the human error part of it. On top of that, it is the traceability of the parts. More and more customers would like no operators and the machine has to run by itself. We have that—a full system of equipment. You just place the basket with parts, or several baskets, and then the robot takes it to the furnace, carburizes, quenches, tempers, washes and then it comes out, completely untouched. Robots are the automated loader. That is the direction.

Another is predictive maintenance, which is a big deal right now. By predictive maintenance, I mean that the system has to predict the failures or the downtimes. A lot of systems, which are available on the market are called “predictive maintenance”, but they are reactive. For example, they have sensors on the machine and if something breaks, it sends you an email message, or whatever. Our SECO/PREDICTIVE, which is our predictive maintenance, is based on an algorithm. The algorithm is written in such a way that the system learns on failures and the more equipment we have connected to it, the more data we have, like everything we have around us right now, all the Googles and Amazons and so on. I think this is the future, as well. So, everything has to be connected to one database to predict what will happen before it happens.

DG: Can you give me an example? Let's say you've got a high temperature fan inside a vacuum furnace. How would the SECO/PREDICTIVE or predictive maintenance work on that?

PZ: I think we would control the vibration on it. I think that's one way to do it. And, at a certain level, it would send a signal – "Watch out! - you are about to have a problem". It is better to do it that way because, then, there is time to order a replacement or schedule something so it will not break. But, the goal is to predict the failure before it happens.

BL: With thoughts of LPC, automation, and predictive maintenance on our minds, we then walked over to a display of various furnaces to see how SECO/VACUUM applied these insights to their own furnaces. Peter began with the Vector, a versatile high pressure gas quench furnace.

BL: With thoughts of LPC, automation, and predictive maintenance on our minds, we then walked over to a display of various furnaces to see how SECO/VACUUM applied these insights to their own furnaces. Peter began with the Vector, a versatile high pressure gas quench furnace.

PZ: This is a single chamber, multipurpose furnace. It is for LPC carburizing and high pressure gas quenching. This is the main furnace and, I think, 70% of what we sell. Maybe this is, like 50%.

Then 20% are the vacuum oil quench furnaces. The vacuum oil quench furnaces heat processing chambers are the same as the Vector but then we can quench it in oil or we can have three chambers that can be continuous production or you can have oil quench on one side and high pressure gas quench on the other side. We call it CaseMaster Evolution. This is our middle step. As I said, our goal is to go for LPC.

Then 20% are the vacuum oil quench furnaces. The vacuum oil quench furnaces heat processing chambers are the same as the Vector but then we can quench it in oil or we can have three chambers that can be continuous production or you can have oil quench on one side and high pressure gas quench on the other side. We call it CaseMaster Evolution. This is our middle step. As I said, our goal is to go for LPC.

But, then, there is another one, the new baby in the family. [Peter then gestures to, what they call, the Super IQ vacuum furnace.]

But, then, there is another one, the new baby in the family. [Peter then gestures to, what they call, the Super IQ vacuum furnace.]

For people, it was not easy to make a switch, so this is like a hybrid. The processing chamber is vacuum carburizing but the quenching chamber is like a traditional atmosphere quench. It is like a pure replacement: you can take one out and put this guy in. You have all the benefits from low pressure carburizing but you operate mainly like an old and traditional furnace. This is to make it easier in the transition.

BL: After learning how certain furnace designs can be helpful to heat treaters who have different processing needs or who are trying to convert to LPC, we then moved to see how LPC is being brought to pit-furnace size loads.

BL: After learning how certain furnace designs can be helpful to heat treaters who have different processing needs or who are trying to convert to LPC, we then moved to see how LPC is being brought to pit-furnace size loads.

PZ: This is another one, another tool in our mission, I would say. This is a pit carburizing furnace but with LPC. Right now, for big, heavy parts, they are carburizing atmosphere in pit furnaces and then they open the furnace and they just transfer it with a crane to an oil tank. This is basically the same, but the pit furnace is with LPC. There is nothing like this on the market right now.

We are trying to bring the LPC advantages to big parts and pit-style carburizers, as well.

BL: From LPC for large loads, we ended our tour with an LPC furnace with an interesting way to maintain traceability.

PZ: This is a single-piece carburizing furnace which we talked about.

So “CaseMaster”, which was the name of our traditional integral quench carburizing furnace in the past, we no longer do. Right now, if we have an RFQ for atmosphere carburizer, we go with LPC.

Thank yous from the group.

To find other Heat Treat Radio episodes, go to www.heattreattoday.com/radio and look in the list of Heat Treat Radio episodes listed.